Erosion-resistant repair coating material capable of being quickly cured at room temperature

A fast-curing, erosion-resistant technology, applied in the field of coatings, can solve problems such as affecting efficiency, long drying time, blade erosion damage, etc., to reduce waiting time and improve process efficiency.

Inactive Publication Date: 2020-10-20

AVIC BEIJING INST OF AERONAUTICAL MATERIALS

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Erosion-resistant coating refers to a coating that can resist gas, liquid, solid or multi-phase coupling erosion. It is widely used on steam turbines, turbines and compressor blades. After the engine has been in service for a period of time, the blades will have different degrees of erosion damage. , At this time, it is necessary to use erosion-resistant repair paint for repair and maintenance. At present, the drying time of the existing erosion-resistant repair paint is long. If the workpiece needs to be transferred to another place for the next step, it will take a long time to wait. In the repair process, most of the workpieces are large-sized workpieces, and the heating and curing process cannot meet the conditions. Therefore, the drying time and room temperature curing time of the coating seriously affect the efficiency of field repair and maintenance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

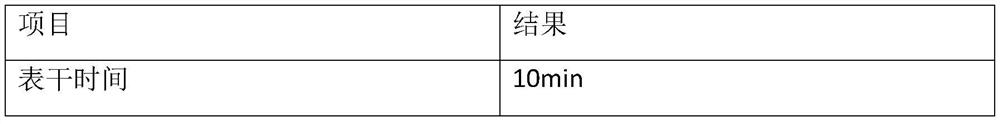

[0023] Component and content (by weight) of Table 1 Embodiment 1

[0024]

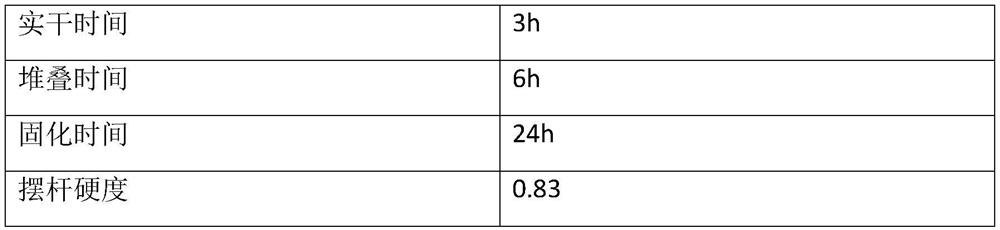

[0025] The test result of table 2 embodiment 1

[0026]

[0027]

Embodiment 2

[0029] Component and content (by weight) of table 3 embodiment 2

[0030]

[0031] The test result of table 4 embodiment 2

[0032] project result Surface dry time 5min hard work time 3h stacking time 4h curing time 24h Pendulum hardness 0.81

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of coating materials, particularly to a scouring-resistant repair coating material capable of being quickly cured at room temperature. According to the invention, the coating material is a two-component coating material, wherein the first component is composed of an epoxy resin, a scouring-resistant filler and a solvent, the second component is composed of a curing agent and an accelerant, the surface drying time of a coating layer prepared through mixed use is within 30 min, the hard drying time is within 2 h, the stacking time is within 6 h, the normal-temperature curing time is within 3 d, and the hardness of a coating layer swing rod is 0.8 or above. According to the invention, room-temperature rapid curing can be realized, waiting time is reduced, arapid repairing effect is achieved, and the scouring resistance requirement of an original coating is met.

Description

technical field [0001] The invention relates to the field of coatings, in particular to an erosion-resistant repair coating capable of rapid curing at room temperature. [0002] technical background [0003] Erosion-resistant coating refers to a coating that can resist gas, liquid, solid or multi-phase coupling erosion. It is widely used on steam turbines, turbines and compressor blades. After the engine has been in service for a period of time, the blades will have different degrees of erosion damage. , At this time, it is necessary to use erosion-resistant repair paint for repair and maintenance. At present, the drying time of the existing erosion-resistant repair paint is long. If the workpiece needs to be transferred to another place for the next step, it will take a long time to wait. In the repair process, most of the workpieces are large-sized workpieces, and the heating and curing process cannot meet the conditions. Therefore, the drying time and room temperature curi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D163/02C09D7/61

CPCC08K2003/2227C09D163/00C09D7/61C08K3/22C08K3/38C08K3/36

Inventor 王志德李静关振威

Owner AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com