Passive-type building stainless steel assembly-type reinforcement structure system

A passive building, stainless steel technology, used in building components, building structures, buildings, etc., can solve the problem that the demand for stainless steel consumption is difficult to meet at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0024] It should be noted that in this embodiment, the stainless steel used is sorbite stainless steel, so the description in this embodiment refers to sorbite stainless steel, but this does not limit the type of stainless steel mentioned in the present invention. In other embodiments, designers can adjust the type of stainless steel according to actual needs.

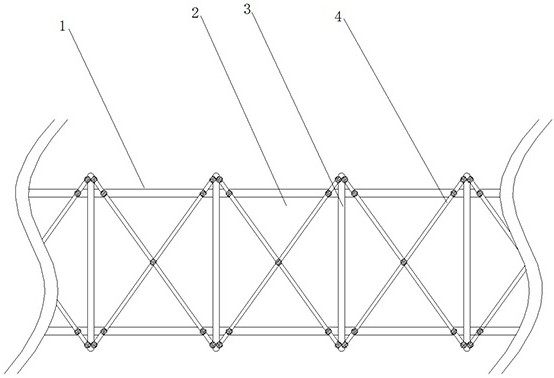

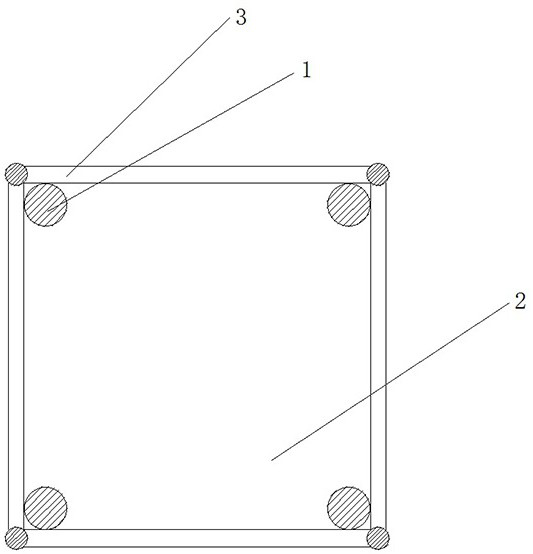

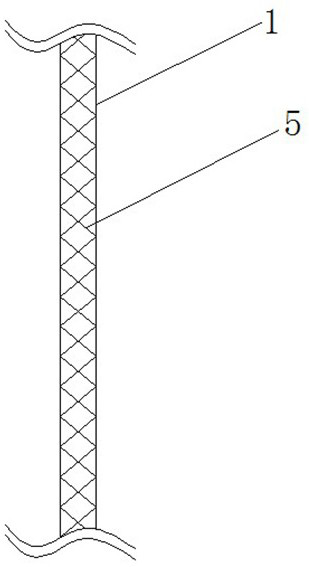

[0025] A stainless steel prefabricated reinforcement structure system for passive buildings, including a plurality of main reinforcements 1 made of stainless steel with the same extension direction. The main reinforcements 1 are arranged as a pouring space 2 for pouring concrete materials. In this embodiment, the four main reinforcements 1 are It can enclose a pouring space 2 for pouring concrete materials without consuming more main reinforcement 1. In other embodiments, the number of main reinforcement can also be three, five or adjusted according to actual needs. The outer peripheral surface of main reinforcement 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com