Method for preparing alum-free vermicelli by utilizing plant extract

A plant extract and alum powder technology, applied in the field of food processing, can solve problems such as loss of brightness and toughness, potential safety hazards, and the use of chemical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Processing of plant extracts:

[0032] (1) wash with water and place the elm bark in clear water to scrub, remove the outer skin, keep the bast and dry it;

[0033] (2) Milling: Cut the bast into knots, put it into a flour mill and grind it into powder, the particle size of the flour milled into powder is 100 mesh, and obtain the elm bark extract, which is reserved for future use.

[0034] Preparation of alum-free vermicelli using plant extracts:

[0035] Step 1 prepares cross-linked starch, takes 100 jin of potato starch and weighs it and places it in a container, then adds 0.6 jin of elm bark extract to the container, stirs and mixes evenly to obtain 100.6 jin of cross-linked starch;

[0036] Step 2: Take 1.5 catties of gorgon powder from the cross-linked starch as the raw material of gorgon powder, put it into a container, add 0.8 catties of hot water at 45 degrees, stir and dissolve, then add 10 catties of boiling water, stir quickly until it becomes a transparent ...

Embodiment 2

[0041] Processing of plant extracts:

[0042] (1) wash with water and place the elm bark in clear water to scrub, remove the outer skin, keep the bast and dry it;

[0043] (2) Milling: Cut the bast into knots, put it into a flour mill and grind it into powder, the particle size of the flour milled into powder is 100 mesh, and obtain the elm bark extract, which is reserved for future use.

[0044] Preparation of alum-free vermicelli using plant extracts:

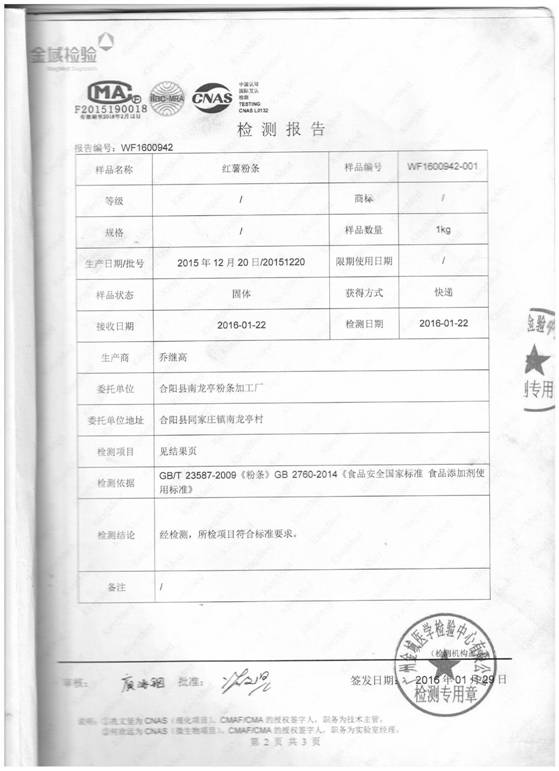

[0045] Step 1 prepares cross-linked starch: Take 200 jin of sweet potato starch and put it in the container after weighing, then add 1.2 jin of elm bark extract to the container, stir and mix evenly to obtain 201.2 jin of cross-linked starch;

[0046] Step 2: Take 3 catties of gorgon powder from the cross-linked starch as the raw material of gorgon powder and put it into a container, add 1.6 catties of hot water at 45 degrees and stir to dissolve, then add 20 catties of boiling water, stir quickly until it becomes a transpar...

Embodiment 3

[0051] Processing of plant extracts:

[0052] (1) wash with water and place the elm bark in clear water to scrub, remove the outer skin, keep the bast and dry it;

[0053] (2) Milling: Cut the bast into knots, put it into a flour mill and grind it into powder, the particle size of the flour milled into powder is 100 mesh, and obtain the elm bark extract, which is reserved for future use.

[0054] Preparation of alum-free vermicelli using plant extracts:

[0055] Step 1 prepares cross-linked starch, takes 80 jin of sweet potato starch and weighs it and places it in a container, then adds 0.5 jin of elm bark extract to the container, stirs and mixes evenly to obtain 80.5 jin of cross-linked starch;

[0056] Step 2: Take 1.2 catties of gorgon powder from the cross-linked starch as the raw material of gorgon powder, put it into a container, add 0.6 catties of hot water at 45 degrees, stir and dissolve, then add 8 catties of boiling water, stir quickly until it becomes a transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com