Raw material stirring device for agricultural feed

A technology of mixing device and feed, which is applied in the directions of feed, application, transportation and packaging, etc., can solve the problems that the mixing mechanism cannot move, the mixing is uneven, and the mixing effect is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

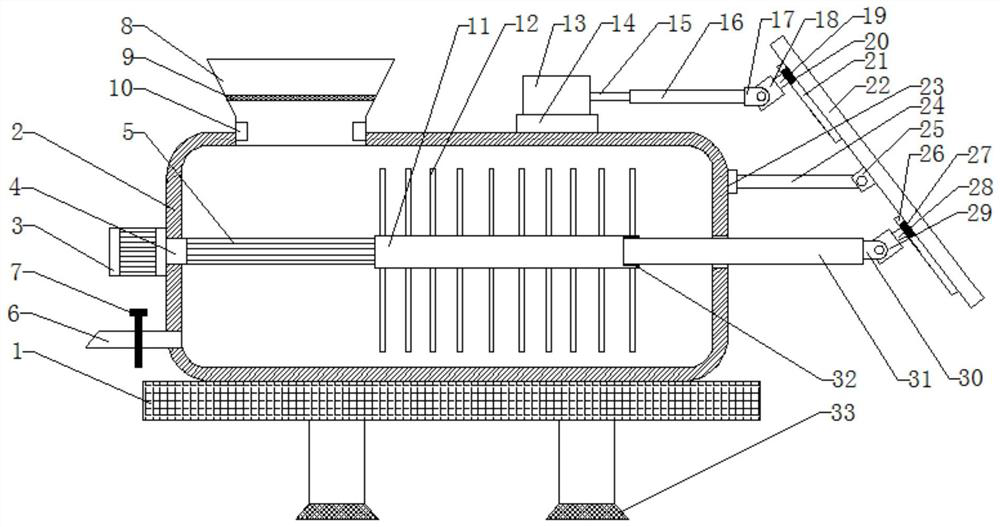

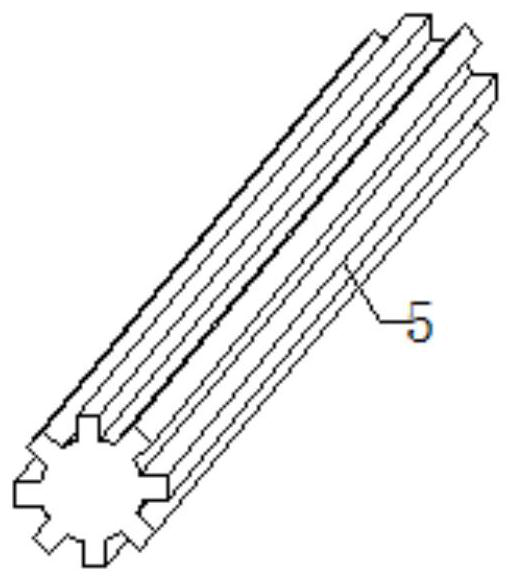

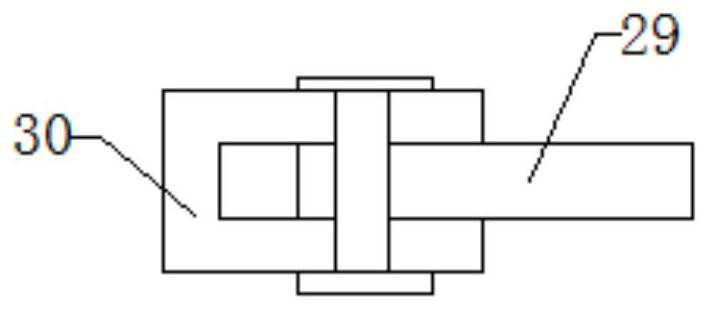

[0023] see Figure 1~2 , in an embodiment of the present invention, a raw material stirring device for agricultural feed, comprising a base 1 and a stirring box 2, the stirring box 2 is fixedly installed on the base 1; a motor 3 is fixedly installed on the left outer wall of the stirring box 2 , the output end of the motor 3 is fixedly connected with a rotating shaft 4, the rotating shaft 4 passes through the left wall of the stirring box 2 and extends to the inside of the stirring box 2, and one end of the rotating shaft 4 located inside the stirring box 2 is fixedly connected with a connecting shaft 5 , the movable sleeve at the right end of the connecting shaft 5 is provided with a stirring shaft 11, and the stirring shaft 11 is fixedly equipped with a stirring rod 12; The transmission rod 31 passes through the right wall of the mixing box 2 and extends to the outside of the mixing box 2; the right end of the second transmission rod 31 is movably connected with the third tr...

Embodiment 2

[0032] see figure 1 In order to make the raw material stirring device for agricultural feed of the present invention filter the impurities in the raw material, this embodiment has made a further improvement on the basis of Embodiment 1. The improvement is: the inside of the feed port 8 is fixedly installed There is a detachable filter layer 9, and a magnetic block 10 for absorbing metal impurities in the raw material is fixedly installed inside the feed port 8.

[0033] The working principle of the present invention is:

[0034]When using the raw material stirring device for agricultural feed of the present invention, at first the raw materials are sequentially added to the mixing tank 2 through the feed port 8, during this process, the impurities in the raw materials will be blocked by the filter layer 9 on the upper side of the filter layer 9, At the same time, the magnetic block 10 will absorb the metal impurities in the raw materials to prevent the quality of the feed fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com