Adjustable crawler-type building garbage treatment combined device

A construction waste, combined device technology, applied in grain processing and other directions, can solve problems such as adjustment and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

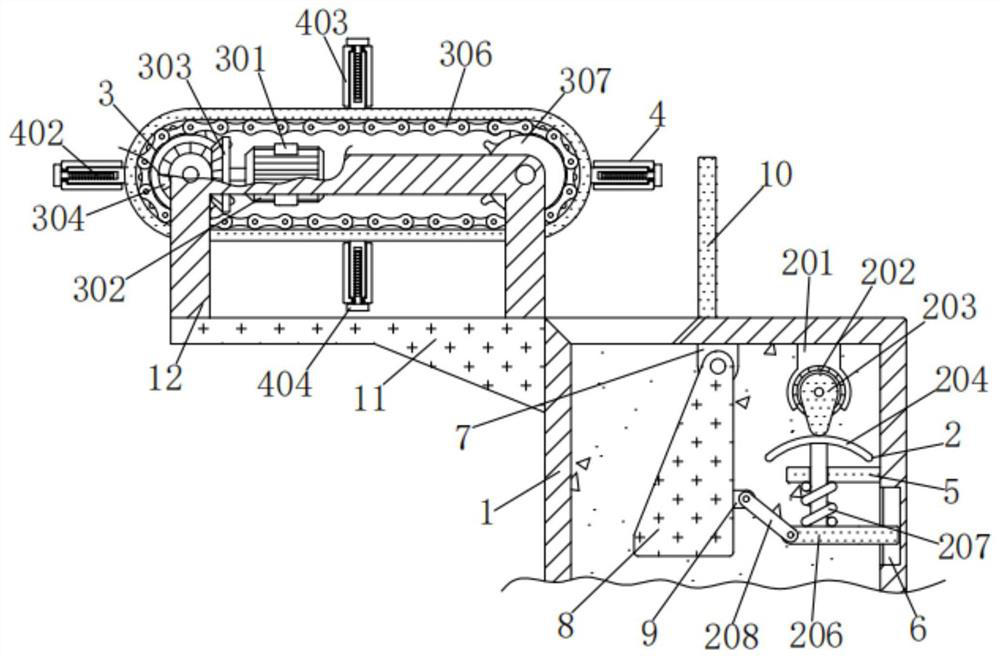

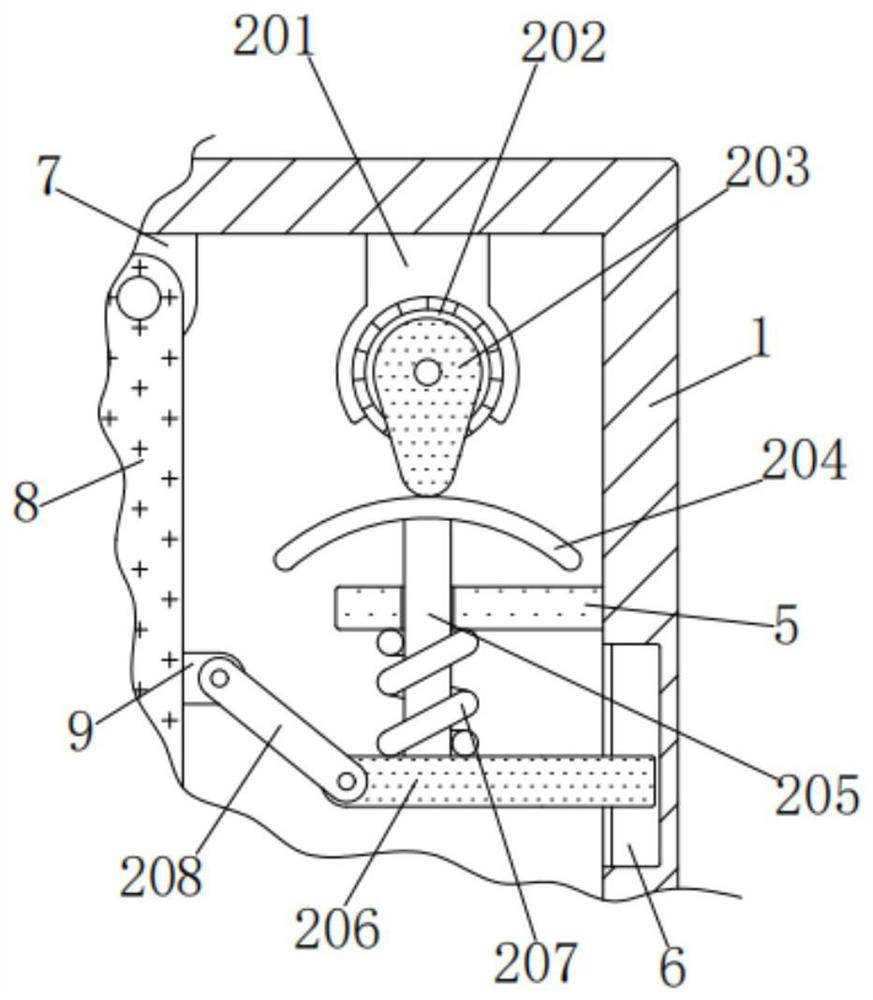

[0043]An adjustable crawler-type combined construction waste treatment device, comprising a housing 1, a horizontal plate 5 is fixedly connected to the right side of the inner wall of the housing 1, a chute 6 is processed on the lower right side of the inner wall of the housing 1, and the top right side of the inner wall of the housing 1 is installed Control mechanism 2 is arranged, and control mechanism 2 comprises first support 201, first motor 202, curved plate 203, arc plate 204, vertical bar 205, thick plate 206, spring 207 and inclined plate 208, the top of first support 201 and shell The top right side of the inner wall of 1 is fixedly connected, and the inner wall of the first bracket 201 is fixedly connected with the top of the outer wall of the first motor 202. The model of the first motor 202 is Y2-1, and the output end of the first motor 202 is connected to the curved plate 203 The inner wall of the vertical bar 205 is fixedly connected, the bottom of the curved pla...

Embodiment 2

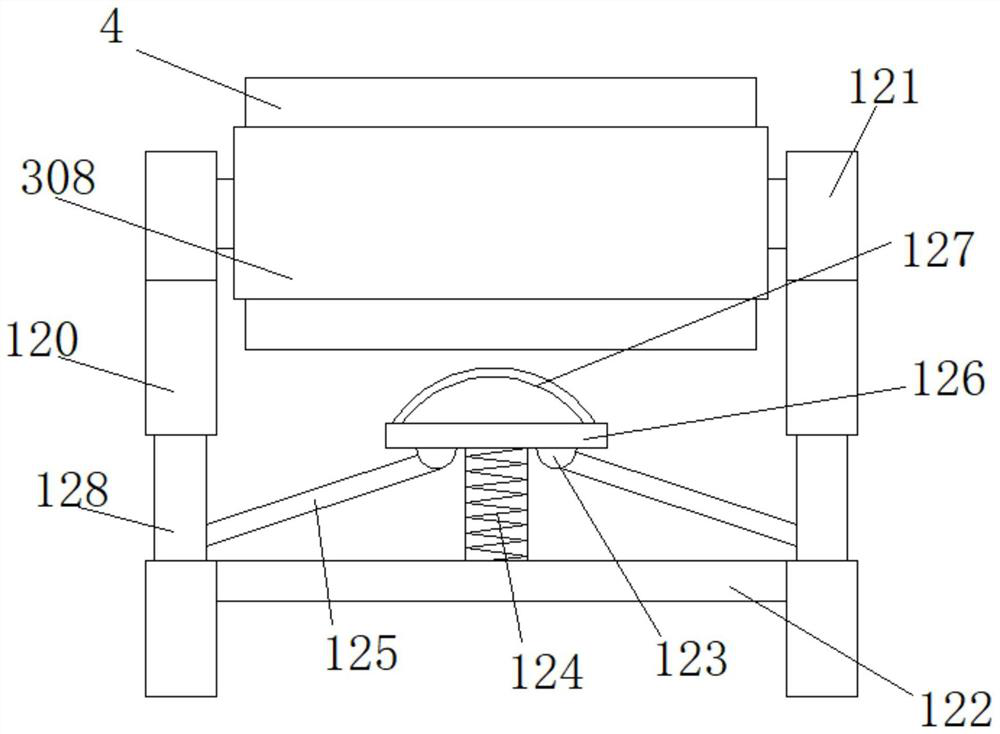

[0045] As an option, see figure 1 , 2 , 5, 6 and 7, adjustable crawler-type construction waste treatment combination device, the inner top of the shell 1 is fixedly connected with the first short plate 7, the front of the first short plate 7 is connected to the top of the curved block 8 in rotation, and the curved block 8 The force is rotated through the front pin shaft of the first short plate 7, the second short plate 9 is fixedly connected to the lower right side of the curved block 8, the front of the second short plate 9 is connected to the top of the slant plate 208 in rotation, The force is rotated through the pin shaft on the front of the second short plate 9, the top left side of the casing 1 is fixedly connected with a support 11, the top of the support 11 is fixedly connected with a square frame 10, and the rear end surface of the square frame 10 is equipped with a power mechanism 3. The power mechanism 3 includes a second bracket 301, a second motor 302, a first g...

Embodiment 3

[0051] As an option, see figure 1 , 5 And 7, an adjustable crawler-type construction waste treatment combination device, the outer wall of the belt 308 is equidistantly equipped with an adjustment mechanism 4, the adjustment mechanism 4 includes a first vertical plate 401, a threaded rod 402, a second vertical plate 403 and a square plate 404, the first The bottom of a riser 401 is fixedly connected to the top of the belt 308, the inner wall of the first riser 401 is threadedly connected with the outer wall of the threaded rod 402, and the threaded rod 402 is forced to rotate up and down through the first riser 401, and the outer wall of the threaded rod 402 The top is rotationally connected with the top of the second riser 403, the threaded rod 402 is forced to rotate through the bearing on the top of the second riser 403, the inner wall of the second riser 403 is matched with the outer wall of the first riser 401, and the threaded rod 402 The top of the shell 1 is affixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com