Rotational flow material distribution device for classificator

A material distributing device and concentrator technology, which is applied in swirling devices, devices whose axial direction can be reversed, solid separation, etc., can solve the problems of poor effect of low-grade mineral materials, waste of resources, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-7 The application is described in further detail.

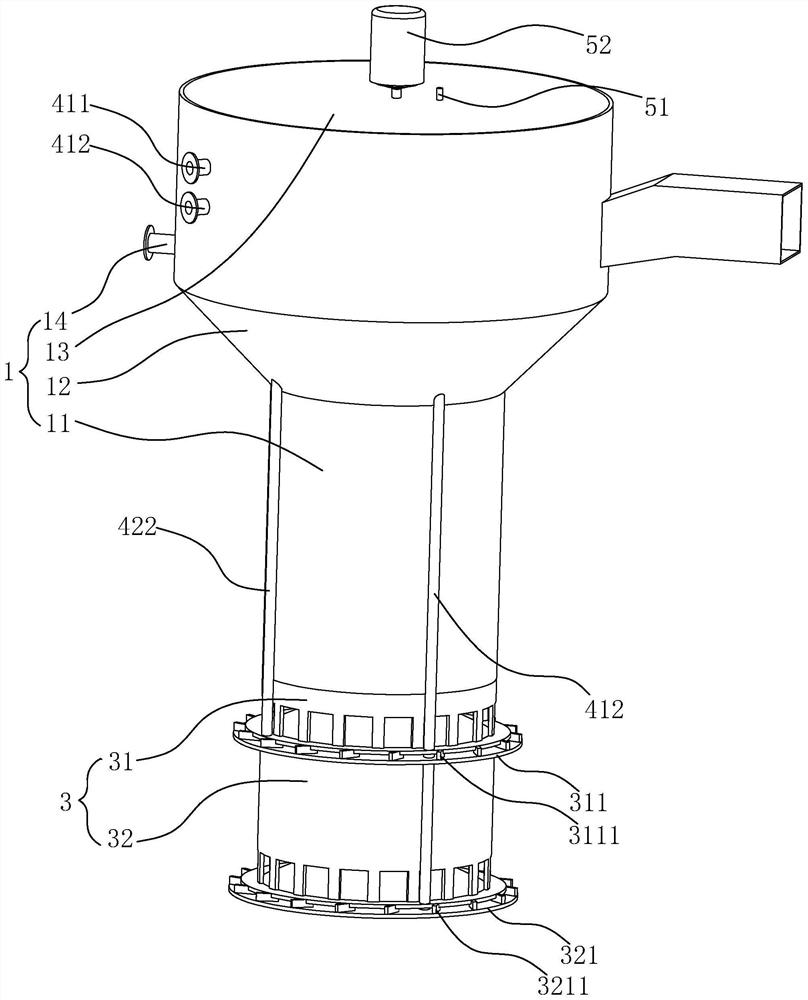

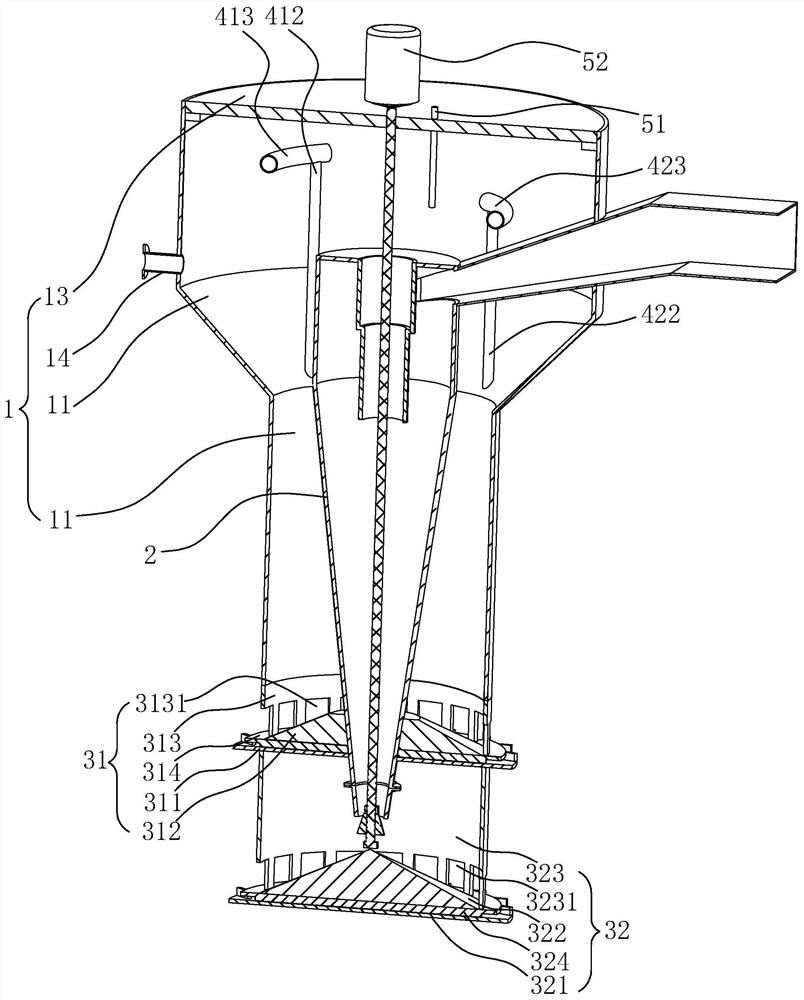

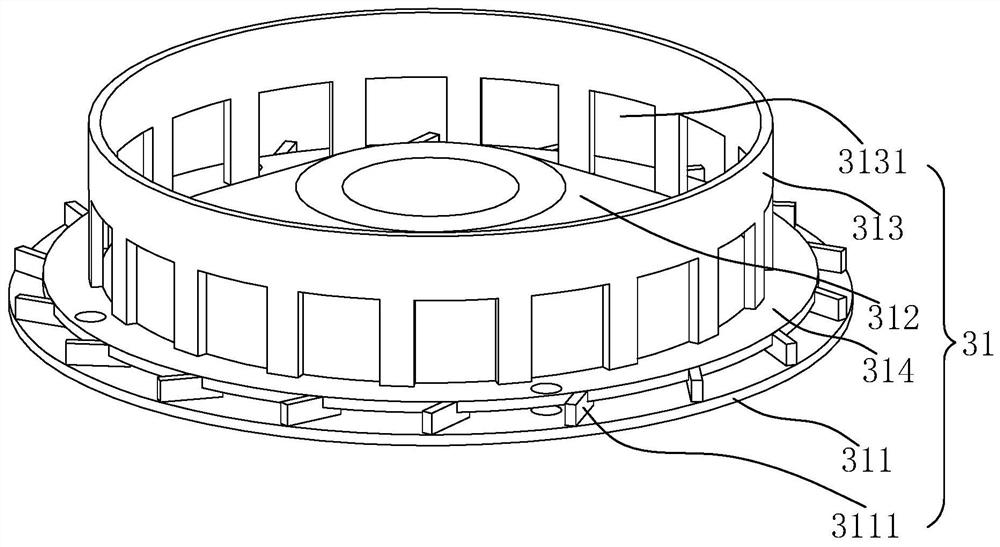

[0045] The embodiment of the present application discloses a swirling flow distribution device used on a concentrator. refer to figure 1 and figure 2 , a swirling flow distributing device used on a concentrating machine, arranged above the sorting barrel of the concentrating machine, including a distributing outer barrel 1 and a cyclone 2, the swirling device 2 is located inside the distributing outer barrel 1, and the swirling flow The top of the cyclone 2 has a first overflow port, the bottom of the cyclone 2 has a bottom flow port, the inlet of the cyclone 2 extends out of the cloth outer barrel 1 through the feed pipe, and the cloth outer barrel 1 is provided with a second Two overflow outlets, the second overflow outlet is provided with a valve, the second overflow outlet is provided with an outwardly extending overflow pipe 14, and the swirl distribution device also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com