Electric control rotating table with lubricating mechanism and for welding production line and application method of electric control rotating table

A welding production line and lubricating mechanism technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not being able to realize the automatic lubrication of the device, reminding to add lubricating oil, shortening the service life of the device, and not being able to clean the welded parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

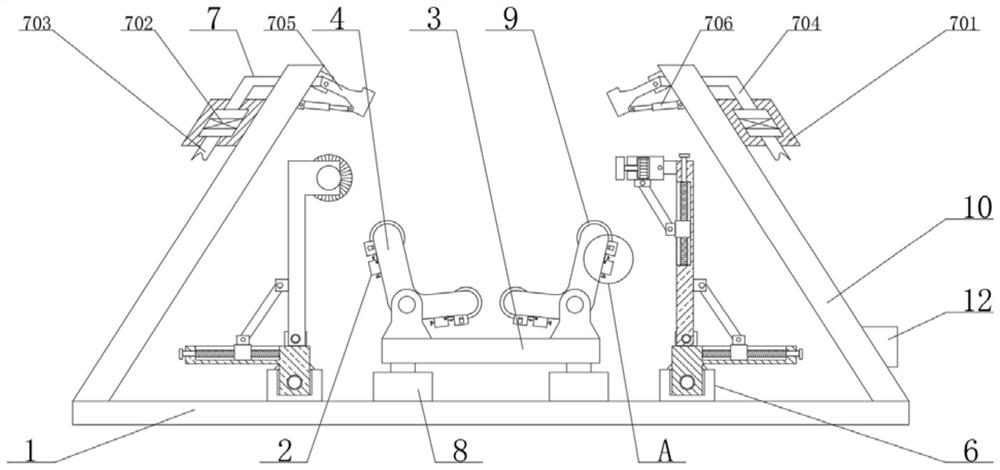

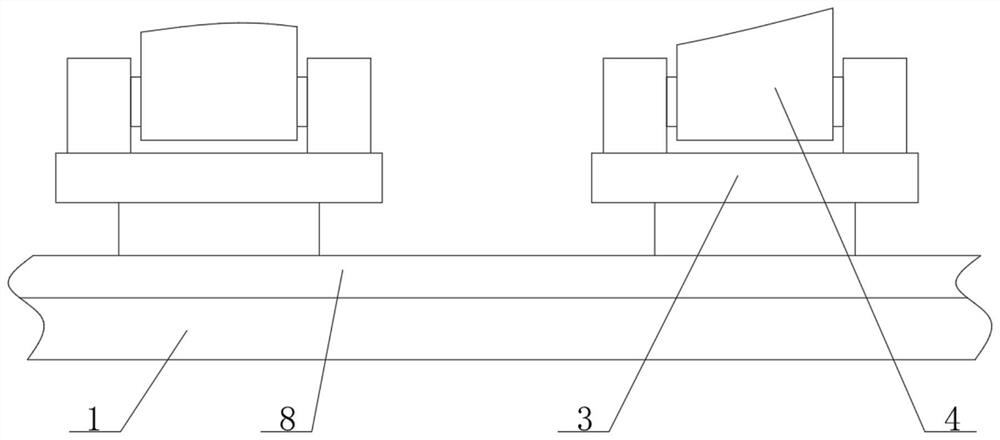

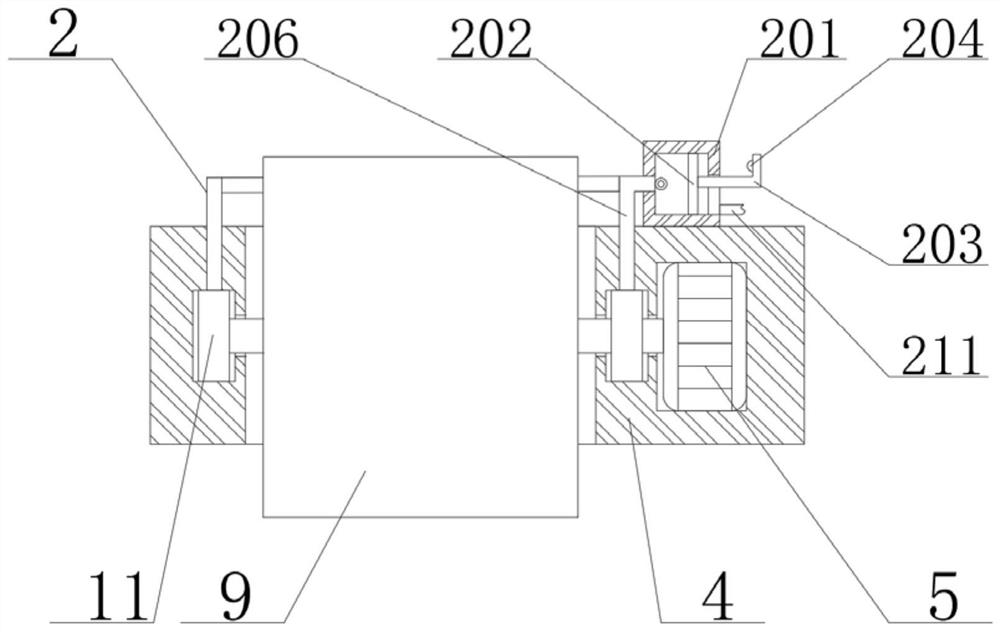

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Figure 7 and Figure 8 , the present invention provides a technical solution:

[0034] An electronically controlled rotary table with a lubricating mechanism for a welding production line and its use method, including a base plate 1, a lubricating device 2, a cleaning device 6 and a protection device 7, the top of the base plate 1 is provided with a cleaning device 6, and the cleaning device 6 includes a second slide Rail 601, second motor 602, first threaded shaft 603, first fixed block 604, first positioning rod 605, second threaded shaft 606, first support block 607, first fixed rod 608, grinder 609, third Slide rail 610, the third motor 611, the third threaded shaft 612, the second fixed block 613, the fourth threaded shaft 614, the second support block 615, the second fixed rod 616, the second positioning rod 617, the fourth motor 618 and Cleaning brush 619, bottom plate 1 top right side is fixedly...

Embodiment 2

[0043] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , the present invention provides a technical solution:

[0044]An electronically controlled rotary table with a lubricating mechanism for a welding production line and its use method, including a base plate 1, a lubricating device 2, a cleaning device 6 and a protection device 7, the top of the base plate 1 is provided with a cleaning device 6, and the cleaning device 6 includes a second slide Rail 601, second motor 602, first threaded shaft 603, first fixed block 604, first positioning rod 605, second threaded shaft 606, first support block 607, first fixed rod 608, grinder 609, third Slide rail 610, the third motor 611, the third threaded shaft 612, the second fixed block 613, the fourth threaded shaft 614, the second support block 615, the second fixed rod 616, the second positioning rod 617, the fourth motor 618 and Cleaning brush 619, bottom plate 1 top right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com