Grinding tool for thickness of sacrificial layer of airplane composite skin

A technology for grinding tools and sacrificial layers, which is used in aircraft assembly, manufacturing tools, grinding machines, etc., and can solve the problems that the level difference is difficult to meet the design requirements, the tolerance is large, and the removal amount cannot be accurately controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

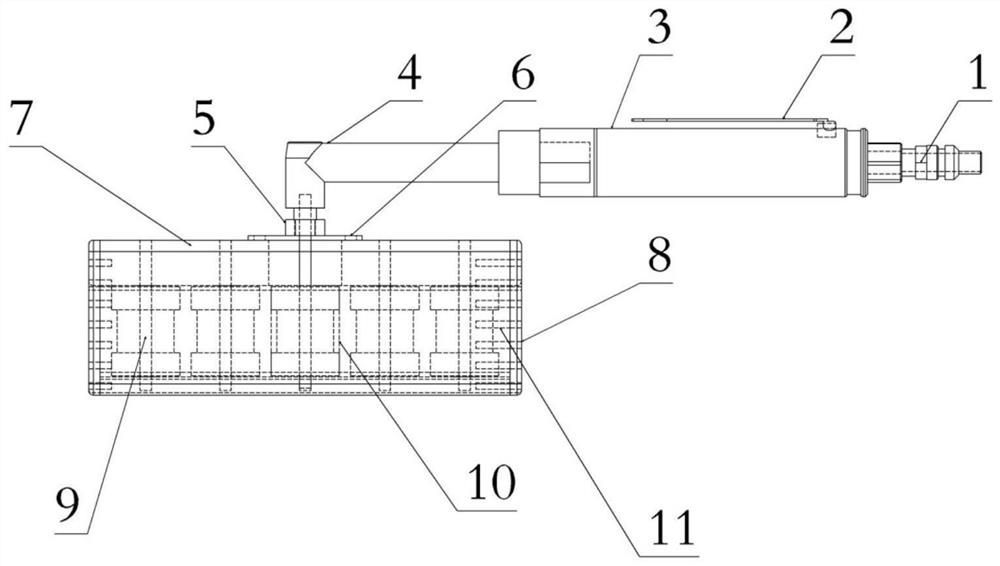

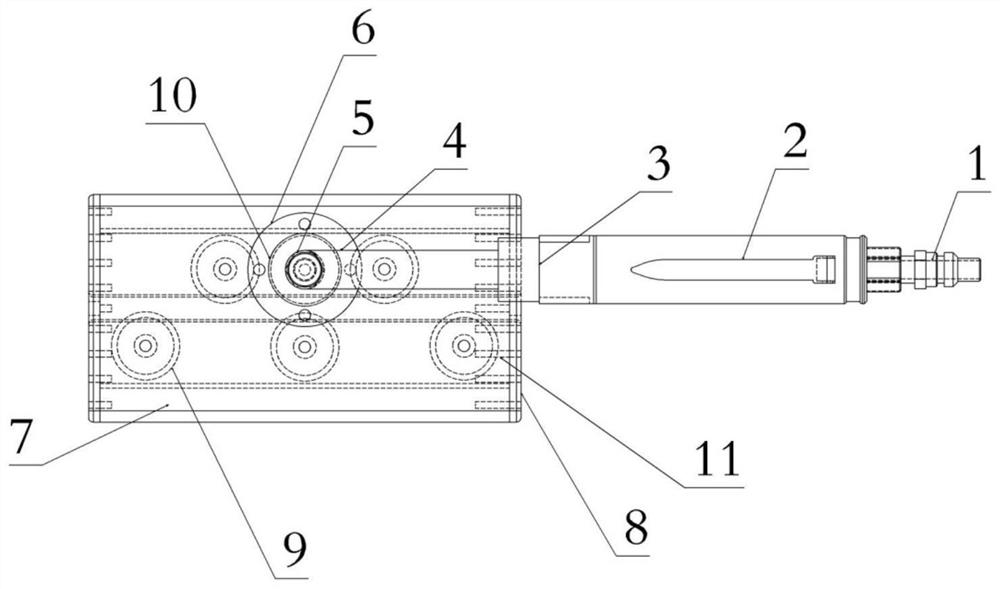

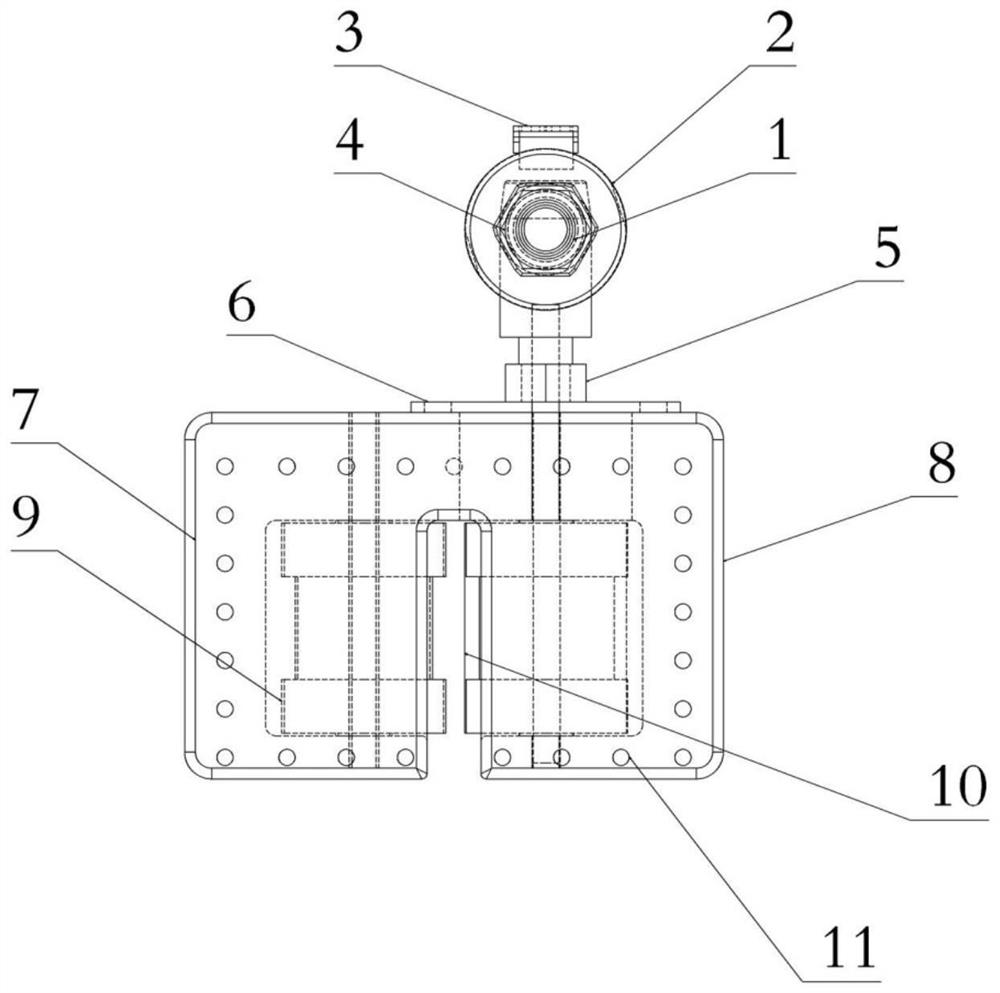

[0013] Aircraft composite skin sacrificial layer thickness grinding tool is composed of the following components: 1 intake nozzle, 2 start switch, 3 turbine motor, 490° angle head, 5 fastening nut, 6 flange, 7 end cavity, 8 sealing Cover, 9 limit wheel, 10 grinding tool, 11 countersunk screw.

[0014] One end of the air intake nozzle 1 is connected to the air source, the other end is connected to the turbine motor 3 through a screw connection, the corner end of the 90° angled head 4 is connected to the fastening nut 5, and the fastening nut 5 is fastened to the grinding tool 10. The elastic nut is disassembled, the end cavity 7 and the flange 6 are connected by bolts, the cover 8 has two front and rear covers, and the countersunk head screw 11 is connected with the end cavity 7 to form a semi-enclosed space, and there are 5 limit wheels 9 in total , bearings are embedded inside, and are connected with the end cavity 7 through an interference fit through the mandrel.

[0015] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com