A kind of high-homogeneous large-size ultra-high-strength steel ingot and its manufacturing method

An ultra-high-strength steel and a manufacturing method technology, which are applied in the field of high-homogeneity large-size ultra-high-strength steel ingots and their manufacturing fields, and can solve the problem of unpredictable large-size steel bars with unsatisfactory homogeneity, unsatisfactory permeability, and not belonging to large-size steel bars. stick level etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

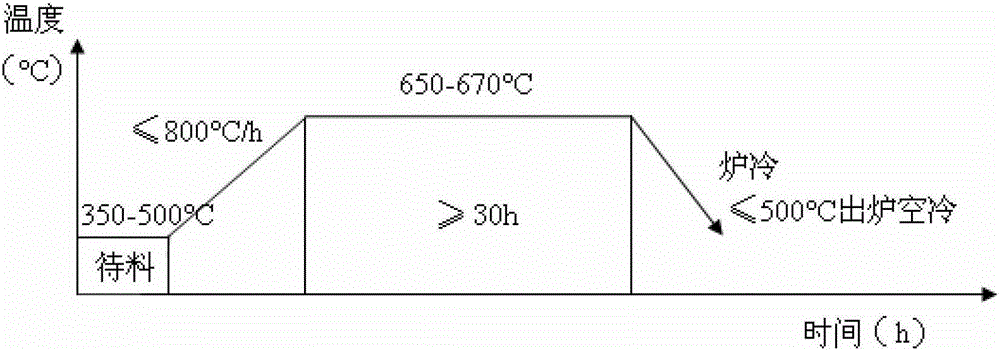

Method used

Image

Examples

Embodiment 1

[0055] (1) Vacuum induction furnace VIM melting

[0056] (a) Raw materials: Raw steel Chemical composition (wt%): C: 0.30%, Si: 0.35%, Mn: 0.04%, S: 0.001%, P: 0.004%, Al: 0.03%, Cu: 0.06%, the rest For Fe. The metal Fe is made of industrial pure iron with special specifications, the specification is 100*100*300, and the surface is smooth, rust-free and dirt-free.

[0057] The raw steel is smelted by EAF+LF+VD three-step method according to the above chemical composition ratio, and it is made after hot rolling, cutting and polishing. The hot rolling is rolled according to the 30# steel process of GB699, and it is delivered to vacuum induction after polishing Furnace for batching.

[0058] (b) Vacuum induction furnace melting:

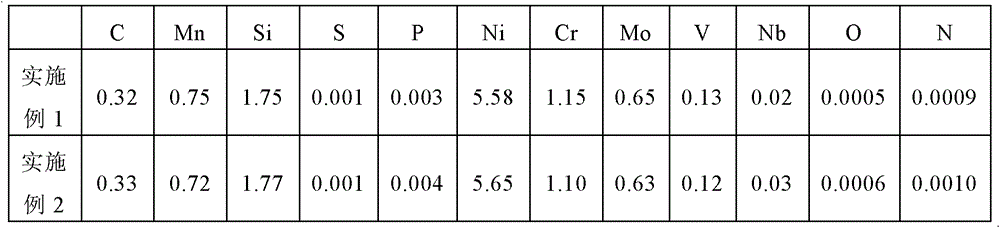

[0059] Melting: dosing according to the chemical composition shown in Table 4 (metal Mo, metal Ni, metal Cr, crystalline Si, metal Mn, Nb, V, carbon particles, etc. have smooth surfaces, no rust, no dirt), and remove all Mn Add the other materials i...

Embodiment 2

[0074] (1) Vacuum induction furnace VIM melting

[0075] (a) Raw materials: Raw steel Chemical composition (wt%): C: 0.30%, Si: 0.35%, Mn: 0.04%, S: 0.001%, P: 0.004%, Al: 0.03%, Cu: 0.06%, the rest For Fe. The metal Fe is made of industrial pure iron with special specifications, the specification is 100*100*300, and the surface is smooth, rust-free and dirt-free.

[0076] The raw steel is smelted by EAF+LF+VD three-step method according to the above chemical composition ratio, and it is made after hot rolling, cutting and polishing. The hot rolling is rolled according to the 30# steel process of GB699, and it is delivered to vacuum induction after polishing Furnace for batching. (b) Vacuum induction furnace melting:

[0077] Melting: Carry out batching according to the chemical composition shown in table 4 (metal Mo, metal Ni, metal Cr, crystalline Si, metal Mn, Nb, V, carbon particles etc. have smooth surface, no rust, no dirt), remove all manganese Add the other materia...

Embodiment 3-4

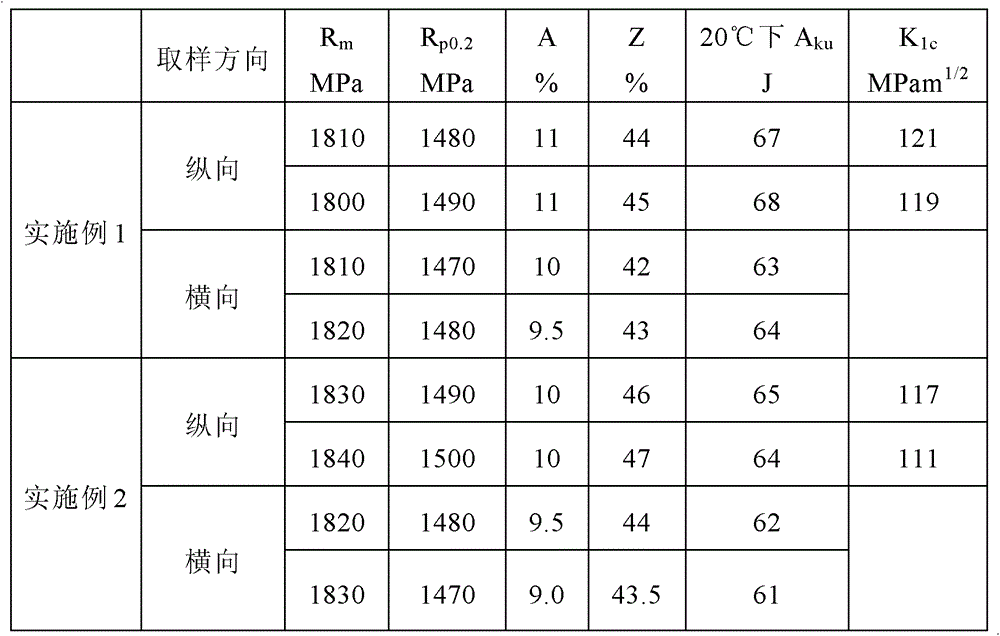

[0099] The chemical composition and mechanical properties of the high-homogeneous large-scale ultra-high-strength steel ingots of Examples 3-4 are shown in Table 7 and Table 8 respectively, and the manufacturing method is the same as that of Example 1.

[0100] Table 7 Units: % by weight

[0101]

[0102] Table 8

[0103]

[0104] The obtained high-homogeneous large-scale ultra-high-strength steel ingots of Examples 3 and 4 were forged by upsetting and drawing with a 4000-ton fast forging machine to obtain steel bars with a diameter of ∮400mm. After testing, the longitudinal mechanical properties of each steel bar were: R m ≥1800MPa,R p0.2 ≥1470MPa, A≥10%, Z≥44%, A ku ≥60J, the ratio of transverse mechanical properties to longitudinal mechanical properties reaches over 92%, meeting the requirement of high homogeneity, and the white spot, dark spot, radial segregation and annual ring segregation in the low-magnification tissue respectively reach AAAB level, excellent I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com