PID control method for industrial robot with preset performance

A technology of industrial robots and control methods, applied in the directions of comprehensive factory control, program control manipulators, manipulators, etc., can solve the problems of high development cost, controller integral saturation, long development cycle, etc., to solve mechanical wear, control accuracy determination, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

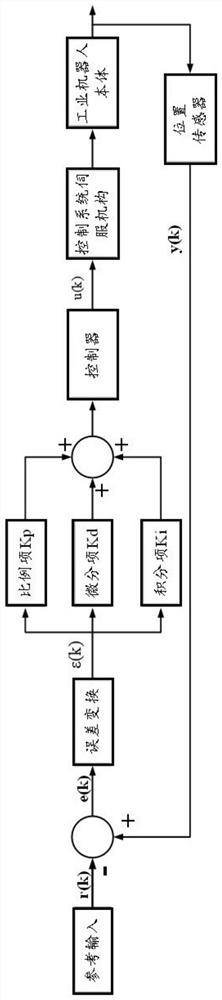

[0051] The traditional PID control method is as follows:

[0052] u(k)=-K p *e(k)-K i *∑e(k)-K d *(e(k)-e(k-1)) / T (1)

[0053] in:

[0054] u(k) represents the controller output;

[0055] e(k) represents the position tracking error;

[0056] K p Indicates the proportionality coefficient;

[0057] K i Indicates the integral coefficient;

[0058] K d Represents a differential system;

[0059] T represents the sampling period.

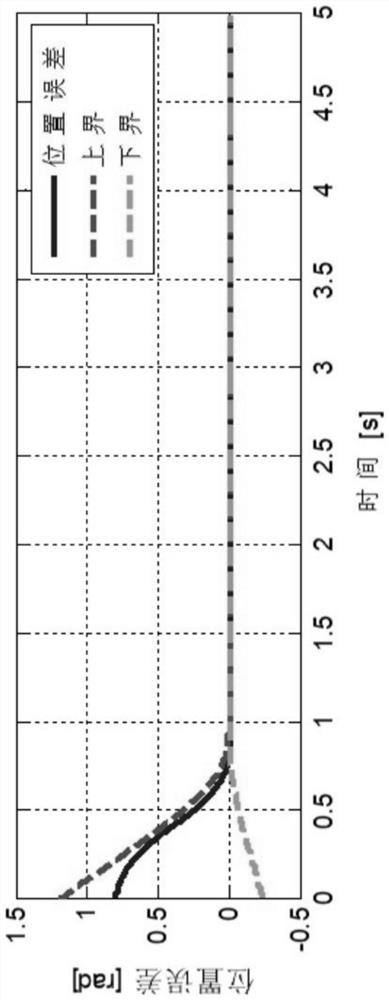

[0060] In the control system of industrial robots, the drift of steady-state control performance is a common phenomenon. With the increase of the service cycle and frequency of industrial robots, this drift of performance will become more and more serious, and even eventually affect the control system of industrial robots service life. Steady-state control performance drift means that the position tracking error of the indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com