Method and device for improving mechanical flexibility of hydraulic valve control cylinder system

A flexible, hydraulic valve technology, applied in the field of servo control, can solve the problems of cumbersome integrated design, increased system design workload, difficult control, etc., to achieve the effect of improving system flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

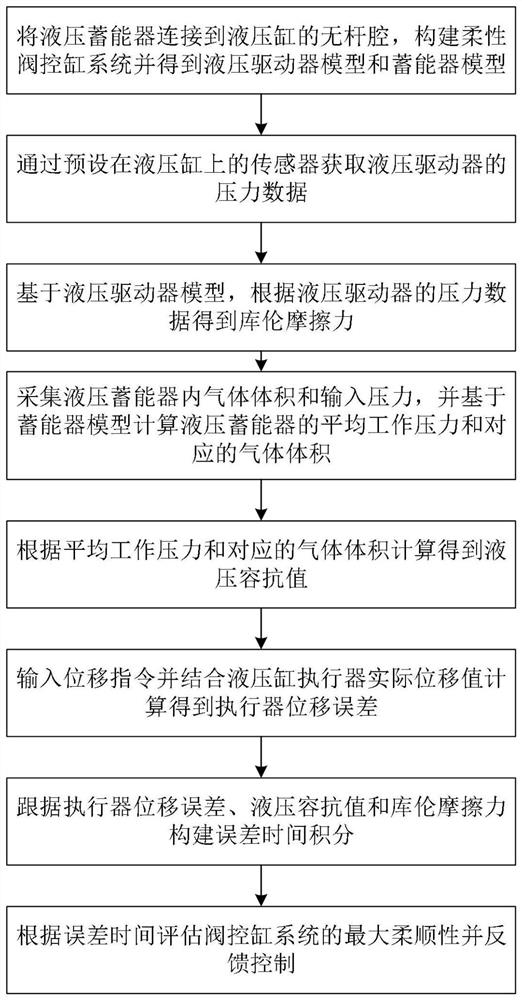

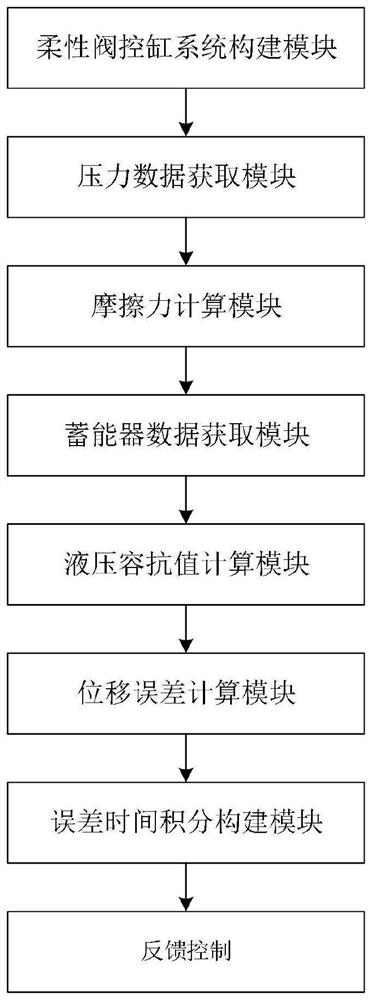

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For the step numbers in the following embodiments, it is only set for the convenience of illustration and description, and the order between the steps is not limited in any way. The execution order of each step in the embodiments can be adapted according to the understanding of those skilled in the art sexual adjustment.

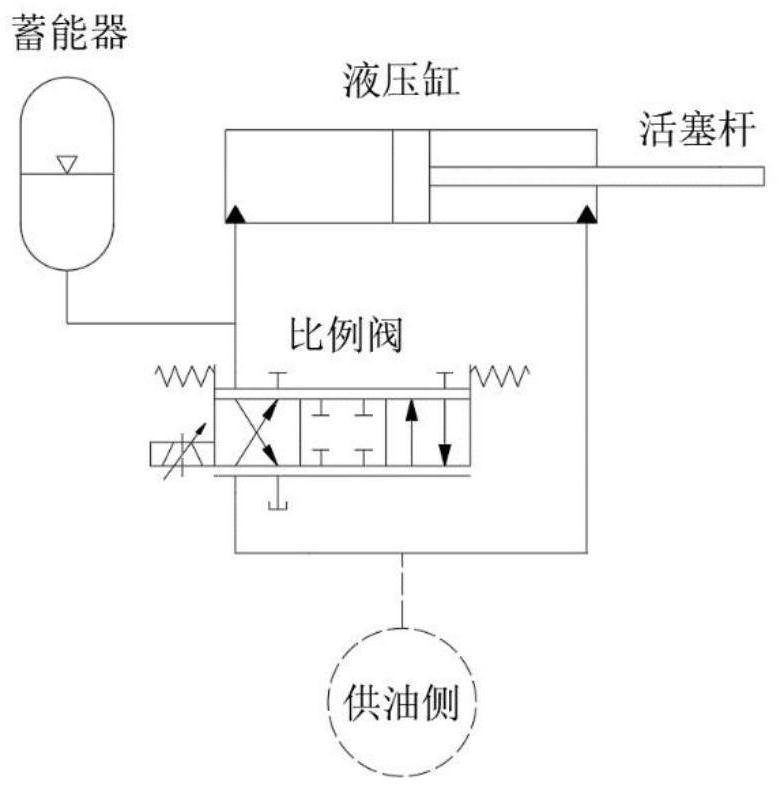

[0041] During the completion of the entire technology, the necessary components of the valve-controlled cylinder system are: hydraulic cylinder, hydraulic accumulator, proportional valve, displacement sensor; configuration relationship: the hydraulic accumulator is connected to the rodless chamber of the hydraulic cylinder through a circuit; The proportional valve is connected to the two chambers of the hydraulic cylinder through a circuit; the displacement sensor is arranged on the hydraulic cylinder; the component c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com