Raw material stirring device for highway bridge duct grouting

A technology for channel grouting and highway bridges, which is applied in cement mixing devices, clay preparation devices, grain processing, etc., can solve the problems of inability to crush bulk raw materials and affect the mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

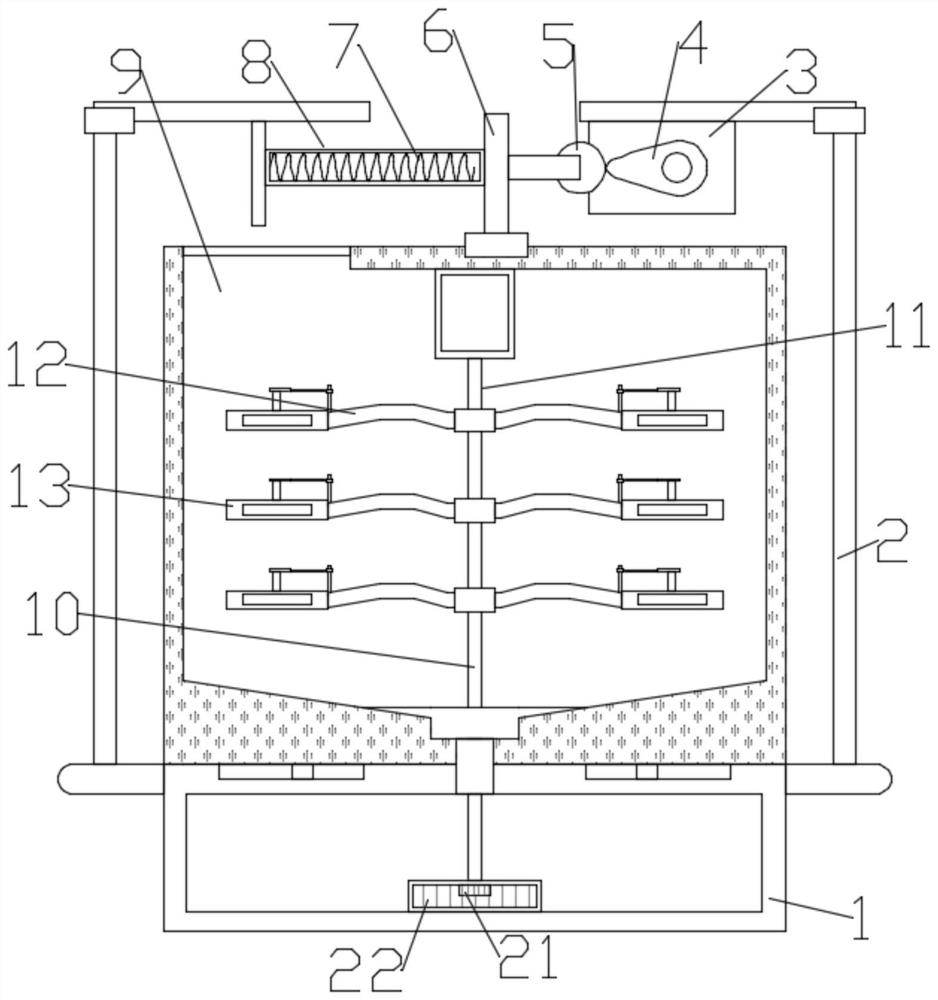

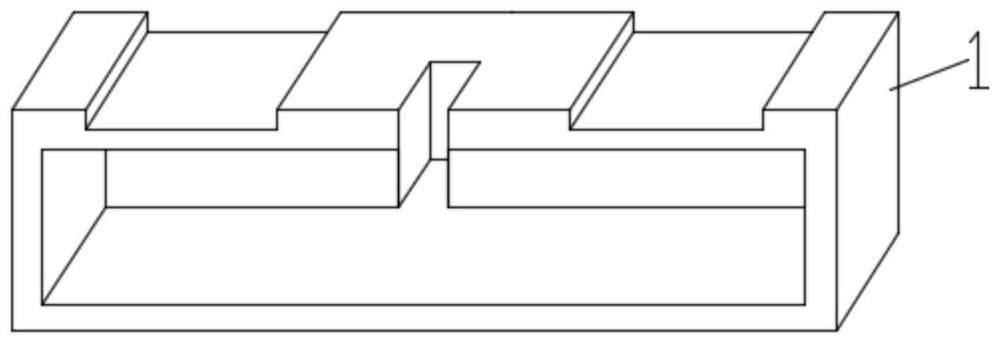

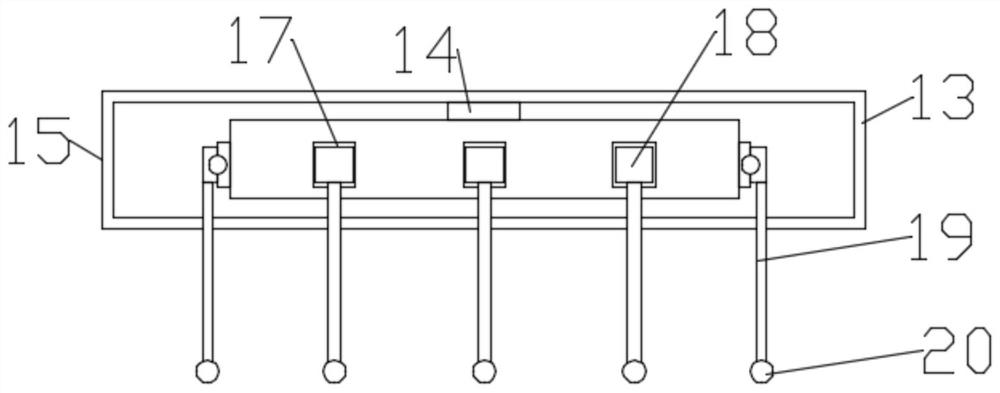

[0024] Such as figure 1 As shown, in the embodiment of the present invention, a kind of raw material mixing device that is used for grouting of highway bridge channel comprises base 1, support 2 and stirring box 9, and the top of base 1 is provided with stirring box 9, and the outside of stirring box 9 is equipped with There is a support 2, and the inside of the stirring box 9 is provided with a stirring assembly 10, and a crushing assembly 13 for crushing raw materials is installed on the stirring assembly 10;

[0025] The top of the bracket 2 is fixedly installed with a motor mounting seat 3, and a servo motor is fixedly installed on the motor mounting seat 3. The output end of the servo motor is connected with a cam 4 through an interference fit. One side of the cam 4 is provided with a column 6, and the bottom of the column 6 is Fixed on the mixing box 9, the side of the column 6 close to the cam 4 is fixedly equipped with an extrusion block 5, the extrusion block 5 is mad...

Embodiment 2

[0032] Such as figure 1 As shown, in the embodiment of the present invention, a kind of raw material mixing device that is used for grouting of highway bridge channel comprises base 1, support 2 and stirring box 9, and the top of base 1 is provided with stirring box 9, and the outside of stirring box 9 is equipped with There is a support 2, and the inside of the stirring box 9 is provided with a stirring assembly 10, and a crushing assembly 13 for crushing raw materials is installed on the stirring assembly 10;

[0033] The top of the bracket 2 is fixedly installed with a motor mounting seat 3, and a servo motor is fixedly installed on the motor mounting seat 3. The output end of the servo motor is connected with a cam 4 through an interference fit. One side of the cam 4 is provided with a column 6, and the bottom of the column 6 is Fixed on the mixing box 9, the side of the column 6 close to the cam 4 is fixedly equipped with an extrusion block 5, the extrusion block 5 is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com