Impact-resistant heat-resistant flame-retardant polyester, polyester product, preparation method and application thereof

A flame-retardant polyester and impact-resistant technology, applied in the field of polymers, can solve the problems of unsatisfactory flame-retardant performance and insufficient heat resistance, and achieve increased toughness, good heat resistance and flame retardancy, and improved elongation at break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In some embodiments, the preparation method specifically includes: reacting the first glycol, terephthalic acid or its esterified product, the second glycol, and an esterification or transesterification catalyst at 160-260°C for 1-8.0 h, then add a polycondensation catalyst and a stabilizer, and react for 1 to 8.0 hours at a temperature of 200 to 300° C. and a vacuum below 300 Pa to obtain an impact-resistant, heat-resistant, and flame-retardant polyester.

[0039] In the above embodiments of the present invention, the structure of the phosphorus-containing aromatic dihydric alcohol is as formula III:

[0040] .

[0041] Formula III

[0042] The phosphorus-containing aromatic dihydric alcohol can be prepared by reacting phenol, p-hydroxybenzaldehyde and DOPO, followed by further hydroxyethylation.

[0043] In some embodiments, the second glycol includes cyclohexanedimethanol.

[0044] In some embodiments, the molar ratio of the phosphorus-containing aromatic diol t...

Embodiment 1

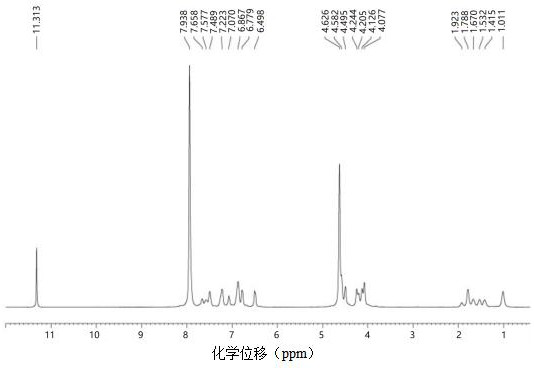

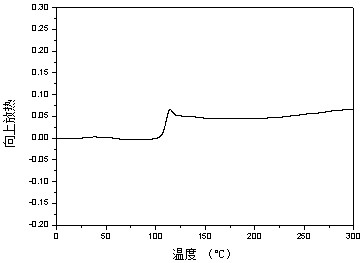

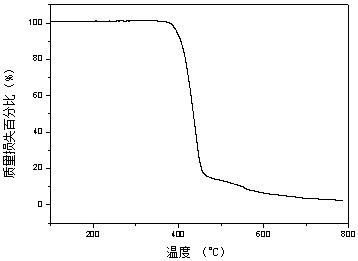

[0088] Example 1 Add dimethyl terephthalate, phosphorus-containing aromatic diol, 1,4-cyclohexanedimethanol, and ethylene glycol into the reactor in a molar ratio of 1:0.20:0.2:2.1, and then add Anhydrous zinc acetate with a molar weight of 1.0‰ of dimethyl terephthalate, heated to 180°C, reacted for 3.5 hours, then added antimony trioxide with a molar weight of dimethyl terephthalate of 0.6‰, di Phosphorous acid with a molar mass of methyl ester of 0.8‰, vacuum degree of 30Pa, heating up to 285°C, and reacting for 4.0h to obtain polyterephthalic acid phosphorus-containing aromatic glycol ethylene glycol cyclohexanedimethanol copolyester, 1 H-NMR such as figure 1 Shown; DSC spectrum such as figure 2 Shown; the glass transition temperature is 108°C, and the TGA spectrum is as image 3 shown. The flame retardant performance test is V0 level, and the elongation at break of the copolyester is 120%.

Embodiment 2

[0089] Example 2 Add dimethyl terephthalate, phosphorus-containing aromatic diol, 1,4-cyclohexanedimethanol, and ethylene glycol into the reactor in a molar ratio of 1:0.15:0.2:1.05, and then add Anhydrous manganese acetate with a molar weight of 0.6‰ of dimethyl terephthalate, heated up to 160°C, reacted for 8.0 hours, then added antimony trioxide with a molar weight of dimethyl terephthalate of 0.5‰, di Triphenyl phosphate with a molar mass of methyl ester of 0.8‰, vacuum degree of 15Pa, heating up to 285°C, and reacting for 4.0h to obtain polyterephthalic acid phosphorus-containing aromatic glycol ethylene glycol cyclohexanedimethanol copolyester, vitrified The transition temperature is 105°C, the flame retardant performance test is V1 level, and the elongation at break of the copolyester is 160%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap