Clothes drying method and washing and drying all-in-one machine adopting clothes drying method

A drying and washing technology, applied in the control device, application, household appliances and other directions of washing machines, can solve the problems of long drying time, poor accuracy and high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

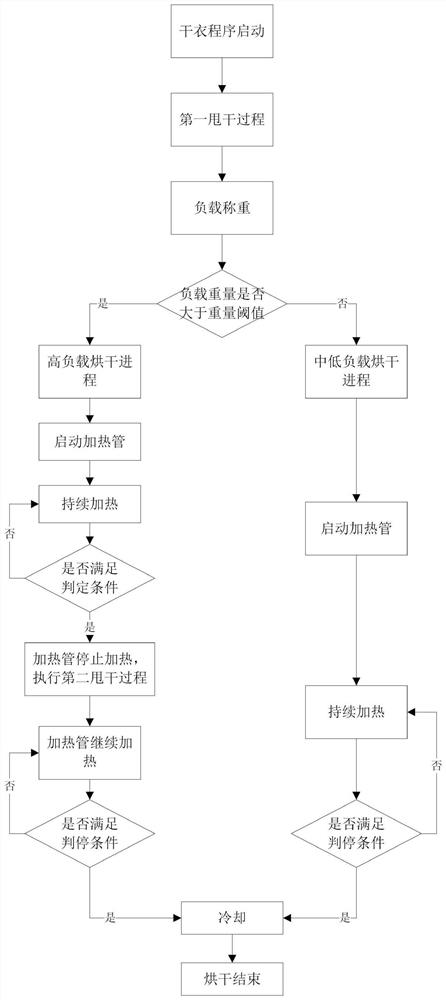

[0043] In the prior art, there are a variety of drying equipment and drying methods. In the drying process of clothes, especially for the drying process of heavy load clothes, the accuracy of drying judgment and drying time are often poor. In order to solve this problem, as shown in the drawings, this embodiment proposes a clothes drying method, including:

[0044] S1, the drying program starts;

[0045] Among them, taking into account the difference in drying equipment, especially the equipment with the washing-drying function as the main function, such as a washer-dryer, etc., it can perform a separate washing function, or a separate drying function, or it can perform Washing-drying is the continuous laundry processing function, so for the execution of a separate drying function, the user turns on the drying function, the user presses the drying start button and other actions, which can be regarded as the drying program start; For the continuous laundry processing function of wa...

Embodiment 2

[0062] In this embodiment, on the basis of Embodiment 1, a supplementary description of the drying method is provided.

[0063] Between step S1 and step S2, an additional spin-drying step is set up, specifically:

[0064] In step S1, after the drying program is started, step S1 further includes: S10, the first spinning process; that is, after the drying program is started, step S10 is executed, and then after the first spinning process is completed, step S2 is executed.

[0065] Among them, for the single drying program, the user puts the laundry into the drum, and the first high-speed spin drying process is the first spin drying process;

[0066] For the washing-drying process, after the last rinsing of the washing process, the spin-drying and dehydration process of the laundry is the first spin-drying process.

[0067] Therefore, in this embodiment, after entering the drying process, the load is first dried for the first time, and then the subsequent steps are performed, so that part ...

Embodiment 3

[0095] This embodiment proposes a clothes drying device on the basis of any of the embodiments 1-3. The clothes drying device adopts the clothes drying method in any of the embodiments 1-3. The clothes drying device It is a device with washing-drying function as its main function, such as a washer-dryer.

[0096] It should be noted that for clothes drying equipment such as a washer-dryer, in the prior art, it is often a drum structure, including conventional structures such as a shell, a drum, a heating tube, a condensation end, and a motor. Components; the drying device in this embodiment also has a corresponding structure, since it is the prior art, it will not be repeated here.

[0097] In addition, on the basis of the clothes drying method proposed in this application, the clothes drying equipment further includes:

[0098] The central processing unit is used to execute the clothes drying method and control the opening and closing of the relevant parts of the clothes drying equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com