Gas diffusion layer for improving water management capability of fuel cell and preparation method of gas diffusion layer

A gas diffusion layer and fuel cell water technology, which is applied to fuel cell parts, fuel cells, electrical components, etc., can solve the problems of moisturizing, drainage effect reduction, no consideration of cathode and anode, and inability to moisturize, etc., to achieve improvement Effects of water management ability, improvement of output performance, and improvement of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

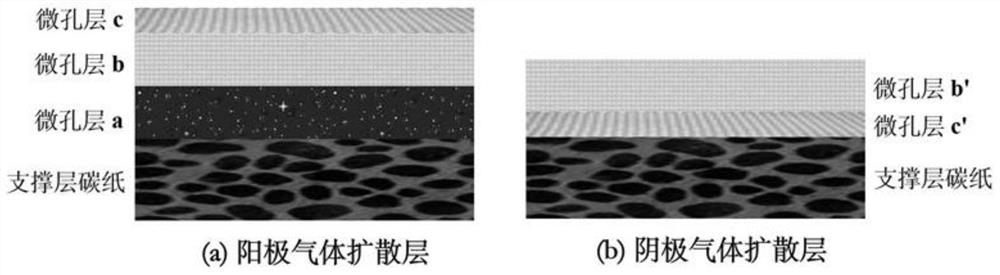

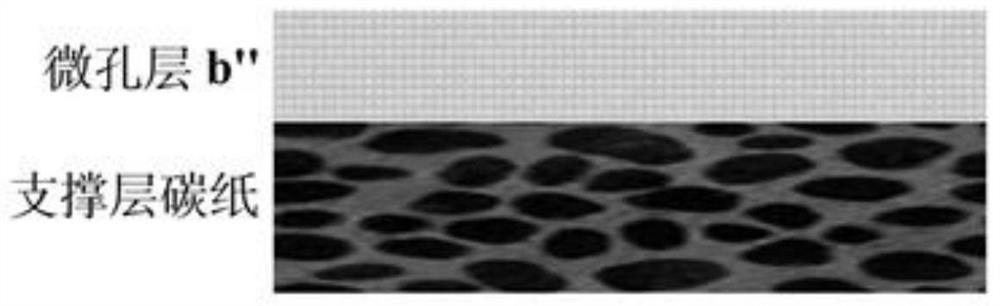

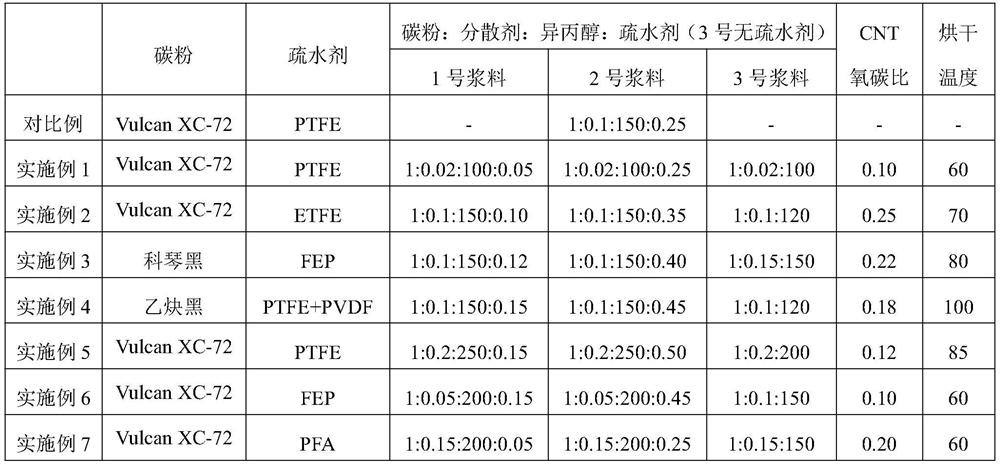

[0032] A method for preparing a gas diffusion layer for improving the water management capability of a fuel cell, comprising the following steps:

[0033] Step 1: Select carbon nanotubes with a diameter of 30nm, and use an acid oxidation method to oxidize the carbon nanotubes, and the oxygen-carbon ratio in the oxidized carbon nanotubes is 0.10;

[0034] Step 2: Mix Vulcan XC-72, dispersant, isopropanol and PTFE according to the mass ratio of 1:0.02:100:0.05 and 1:0.02:100:0.25 respectively, and make a slurry evenly by stirring, ultrasonic and sand milling Material No. 1 and slurry No. 2; the oxidized carbon nanotubes, dispersant and isopropanol were mixed in a mass ratio of 1:0.02:100, and the slurry No. 3 was uniformly mixed by stirring, ultrasonication, and sand milling;

[0035] Step 3: Apply slurry No. 1 on the surface of the support layer carbon paper, dry at 60°C to form microporous layer a, apply slurry No. 2 on the surface of microporous layer a, and dry at 60°C to fo...

Embodiment 2

[0039] A method for preparing a gas diffusion layer for improving the water management capability of a fuel cell, comprising the following steps:

[0040] Step 1: Select carbon nanotubes with a diameter of 50nm, and use an electrochemical oxidation method to oxidize the carbon nanotubes. The oxygen-to-carbon ratio in the oxidized carbon nanotubes is 0.25;

[0041] Step 2: Mix Vulcan XC-72, dispersant, isopropanol and ETFE according to the mass ratio of 1:0.1:150:0.10 and 1:0.1:150:0.35 respectively, and make a slurry evenly by stirring, ultrasonic and sand milling Material No. 1 and slurry No. 2; the oxidized carbon nanotubes, dispersant and isopropanol were mixed in a mass ratio of 1:0.1:120, and the slurry No. 3 was uniformly mixed by stirring, ultrasonication, and sand milling;

[0042] Step 3: Apply slurry No. 1 on the surface of the support layer carbon paper, dry at 70°C to form microporous layer a, apply slurry No. 2 on the surface of microporous layer a, and dry at 70°...

Embodiment 3

[0046] A method for preparing a gas diffusion layer for improving the water management capability of a fuel cell, comprising the following steps:

[0047] Step 1: Select carbon nanotubes with a diameter of 100nm, and use an electrochemical oxidation method to oxidize the carbon nanotubes. The oxygen-to-carbon ratio in the oxidized carbon nanotubes is 0.22;

[0048] Step 2: Mix Ketjen Black, dispersant, isopropanol and FEP according to the mass ratio of 1:0.1:150:0.12 and 1:0.1:150:0.40, respectively, and make a slurry evenly by stirring, ultrasonic and sand milling No. 1 and No. 2 slurry; the oxidized carbon nanotubes, dispersant and isopropanol are mixed according to the mass ratio of 1:0.15:150, and the slurry No. 3 is uniformly mixed by stirring, ultrasonic and sand milling;

[0049] Step 3: Apply slurry No. 1 on the surface of the support layer carbon paper, dry at 80°C to form microporous layer a, apply slurry No. 2 on the surface of microporous layer a, and dry at 80°C t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com