Rotary air preheater system and working method thereof

An air preheater, working method technology, applied in the direction of combustion method, lighting and heating equipment, combustion product treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

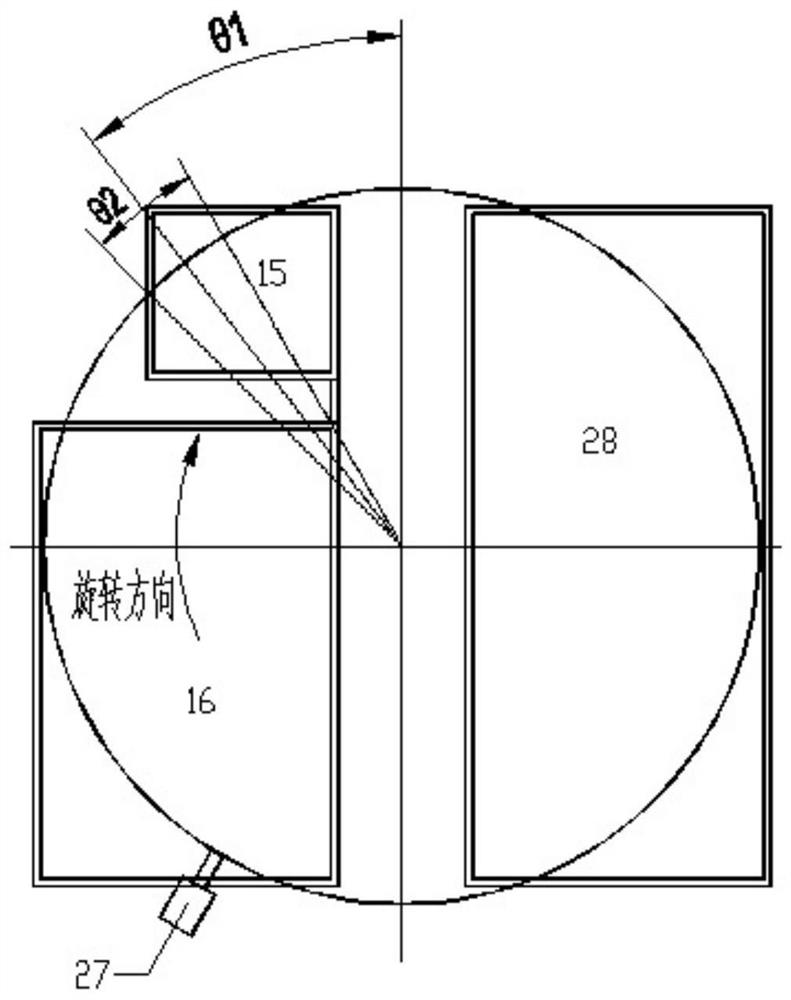

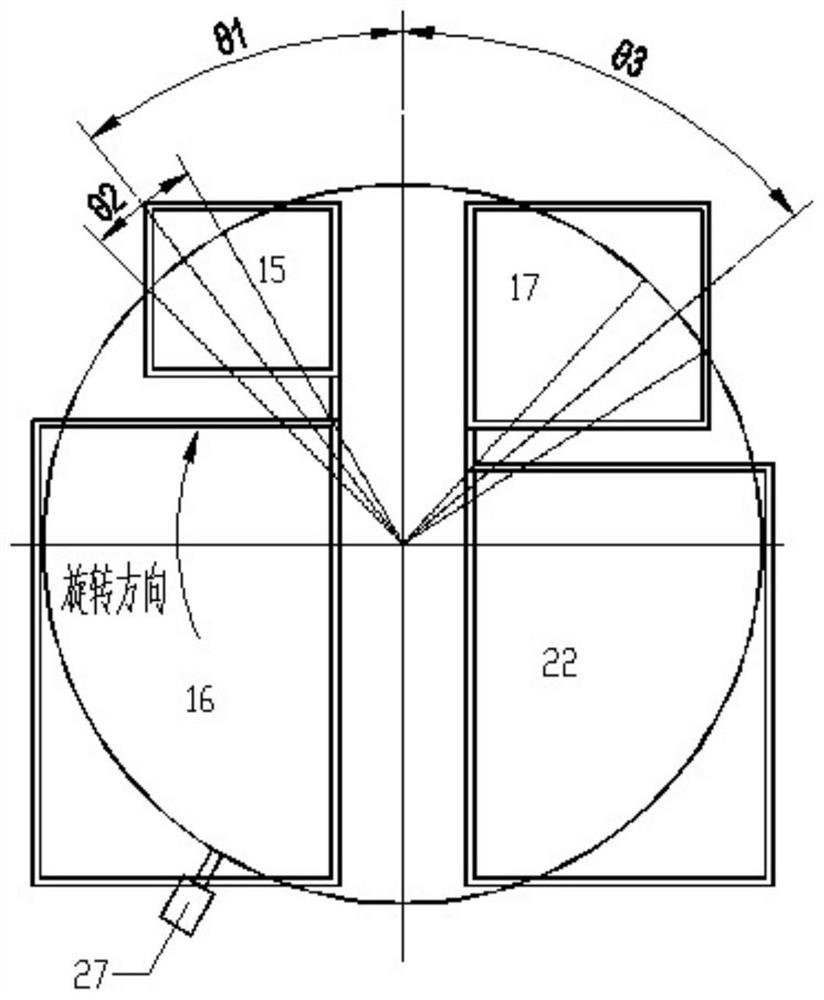

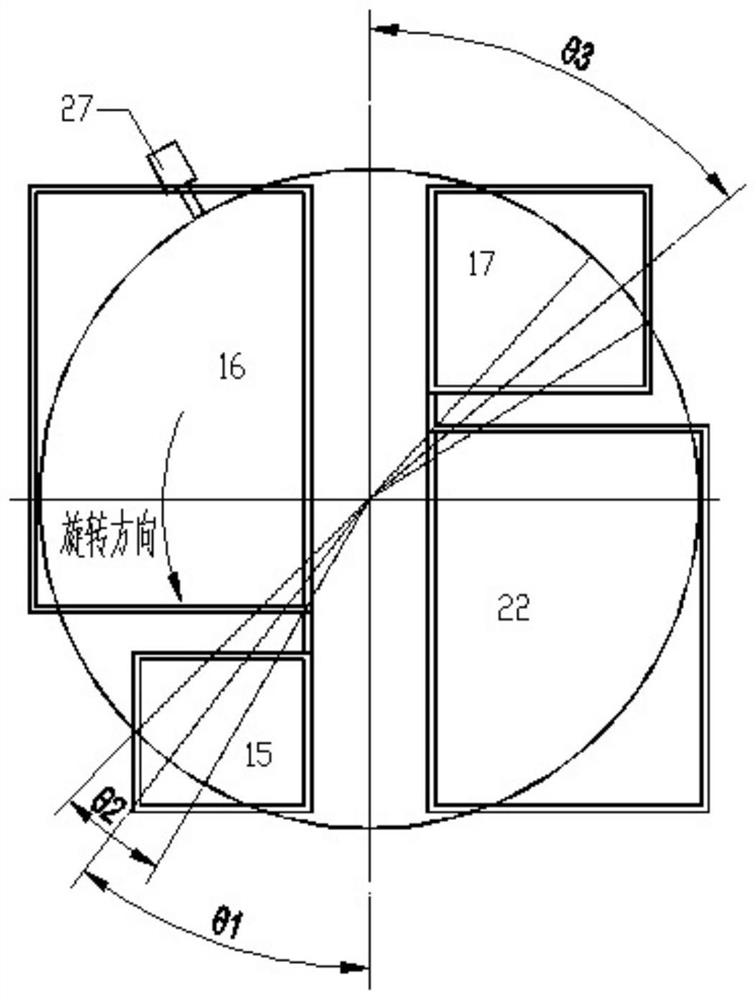

[0055] Such as figure 2 (forward rotation mode), Figure 5 , Figure 6 and Figure 7 ~ Figure 9 As shown, for a 600MW unit, the original design air preheater is a three-compartment rotary air preheater with a rotating heating surface (hereinafter referred to as the traditional three-compartment), which adopts a modular compartment structure, and the air preheater rotor is set There are heat exchange elements, and all heat storage elements are installed in 48 compartments, and the angle of the center of each compartment is 7.5°. After being modified by applying the present invention, its air preheater has a structure of double smoke chambers and quartered chambers, that is, the 24 chambers on the flue gas side are divided into two parts, one part is the unblocking smoke chamber 15, and the rotation direction of the flue gas side is divided into two parts. It consists of three modulus compartments at the end (smoke compartment number 22-24), the corresponding central angle θ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com