Forced centering device capable of being freely lifted, recycled and capable of achieving integrated operation

A forced centering and free technology, applied in the field of measuring instruments, can solve the problems of unobservable, low precision, low operating efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The embodiment of the present invention is a forced centering device that can be freely lifted, recycled and integrated. The forced centering device is suitable for all foundation pit projects, especially for foundation pits with large areas and irregular shapes (pit in pit, The foundation pit project of continuous pit) has better economic benefits. In addition, the forced centering device can also be better applied to foundation pit monitoring.

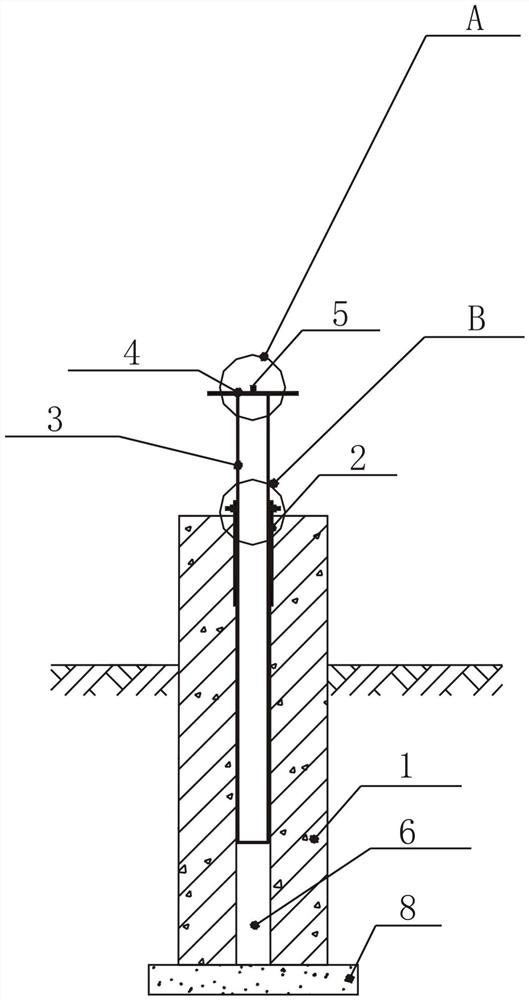

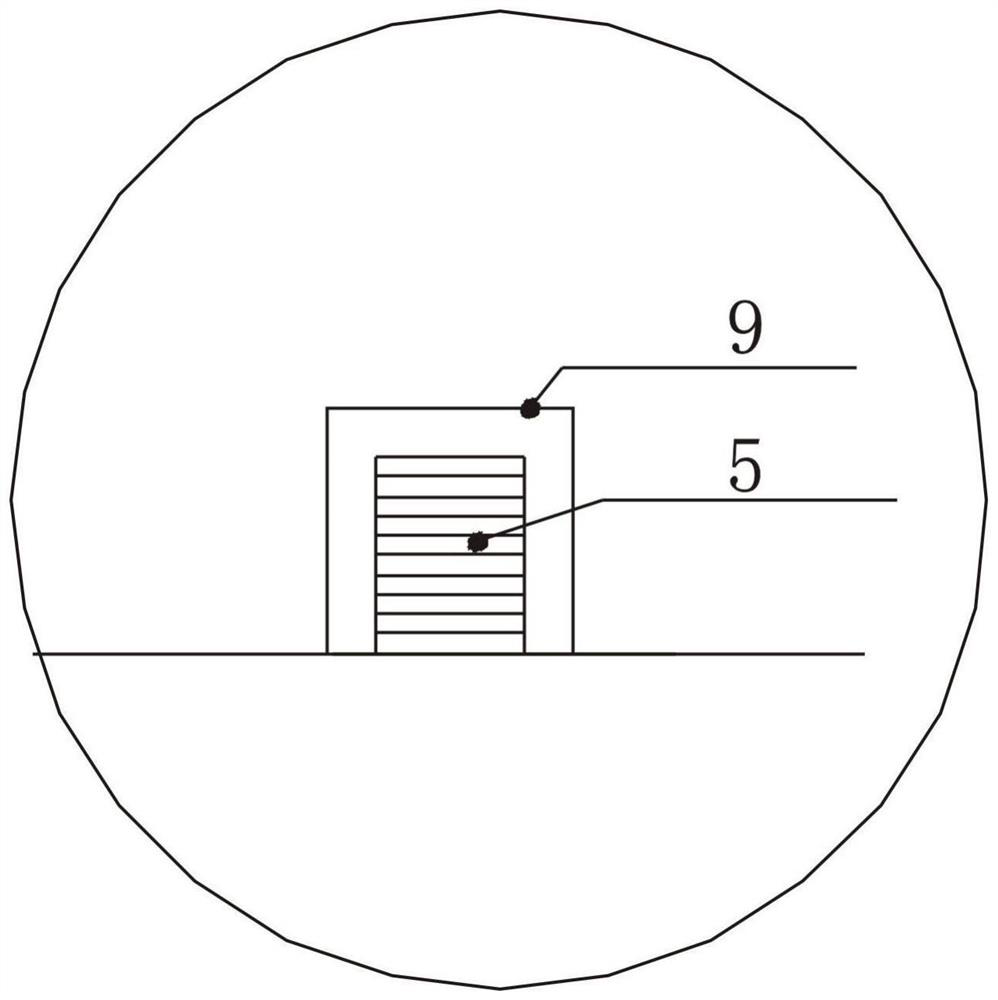

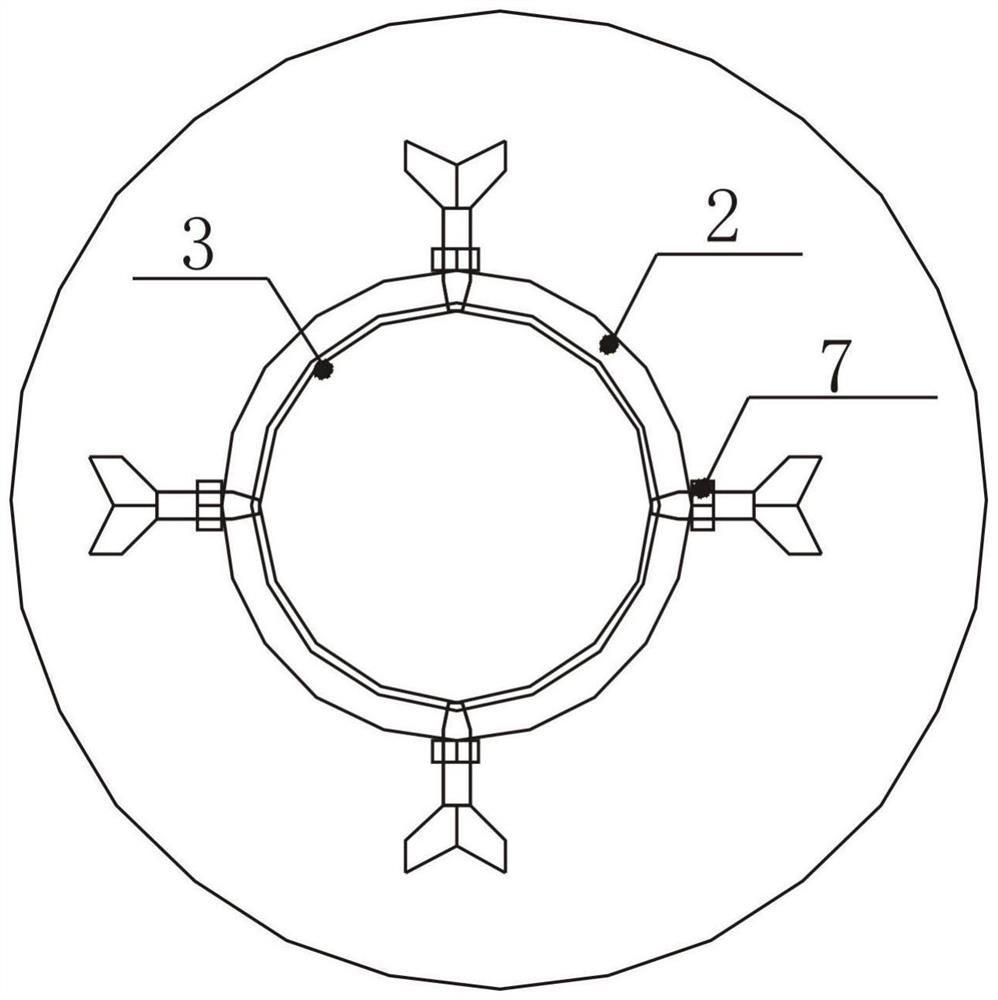

[0040] Such as Figure 1-4 As shown, the forced centering device includes a concrete pier 1 , a steel casing 2 , a steel pipe column 3 , an instrument erection platform 4 and a centering screw 5 .

[0041] specific,

[0042] Such as figure 1 As shown, two-thirds of the concrete pier 1 is buried underground, and the center of the concrete pier 1 is provided with a circular lifting channel 6 along its axial direction, and the steel casing 2 is embedded in the top opening of the circular lifting channel 6. The steel pipe colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com