An Automatic Verification Method for Standard Platinum Resistance Thermometer

A thermometer and platinum resistance technology, applied in the field of automatic verification of standard platinum resistance thermometers, can solve problems such as damage to platinum resistance thermometers and fixed points, and achieve the effects of saving manpower, stable operation, and avoiding accidental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

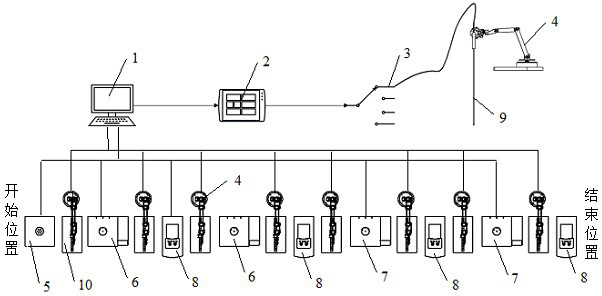

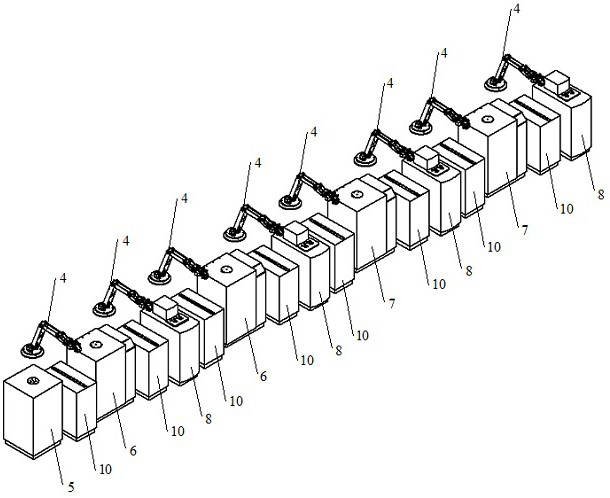

[0022] see Figure 1 to Figure 2 , in this embodiment, an automatic verification method for a standard platinum resistance thermometer, the system includes a computer 1, a precision temperature measuring bridge 2, a transfer switch 3, a flexible grabbing device 4, an annealing furnace 5, and a metal fixed point device 6 , No. 2 metal fixed point device 7, water triple point bottle 8, standard platinum resistance thermometer 9, and waiting area 10.

[0023] The precision temperature measuring bridge 2 is used to measure the resistance value of the tested standard platinum resistance thermometer 9, the transfer switch 3 is used to switch between different tested standard platinum resistance thermometers 9 and the precision temperature measuring bridge 2, and the flexible grabbing device 4 Used to grasp the tested standard platinum resistance thermometer 9 to realize automatic operation, the annealing furnace 5 is used for the annealing operation of the tested standard platinum r...

Embodiment 2

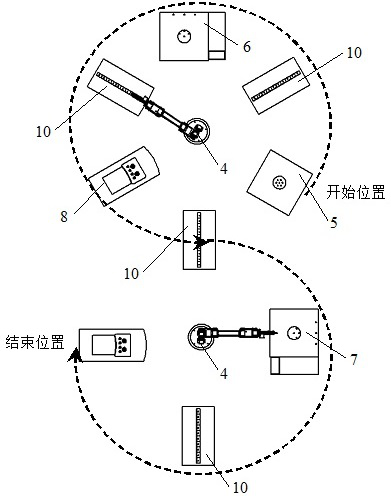

[0033] see Figure 3 to Figure 4 , in this embodiment, an automatic verification method for a standard platinum resistance thermometer, the system includes a computer 1, a precision temperature measuring bridge 2, a transfer switch 3, a flexible grabbing device 4, an annealing furnace 5, and a metal fixed point device 6 , No. 2 metal fixed point device 7, water triple point bottle 8, standard platinum resistance thermometer 9, and waiting area 10.

[0034] The precision temperature measuring bridge 2 is used to measure the resistance value of the tested standard platinum resistance thermometer 9, the transfer switch 3 is used to switch between different tested standard platinum resistance thermometers 9 and the precision temperature measuring bridge 2, and the flexible grabbing device 4 Used to grasp the tested standard platinum resistance thermometer 9 to realize automatic operation, the annealing furnace 5 is used for the annealing operation of the tested standard platinum r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com