Grating structure, optical waveguide and near-to-eye display system

An optical waveguide and grating technology, applied in the optical field, can solve the problems of low degree of freedom in design, few adjustable parameters, and poor diffraction efficiency of diffractive waveguides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

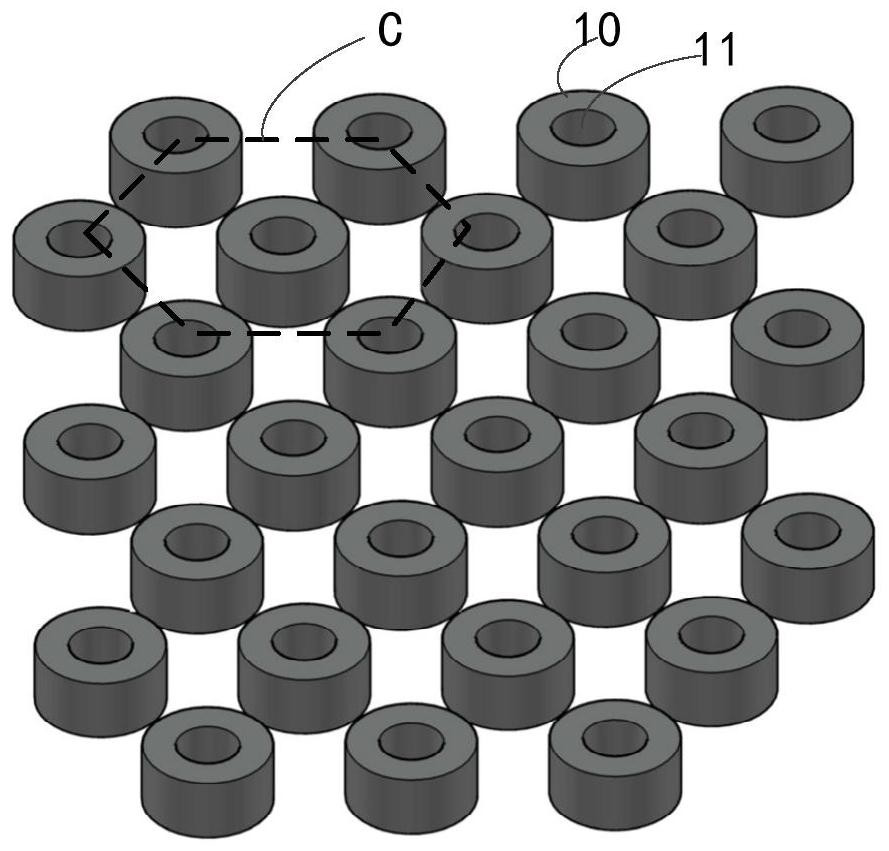

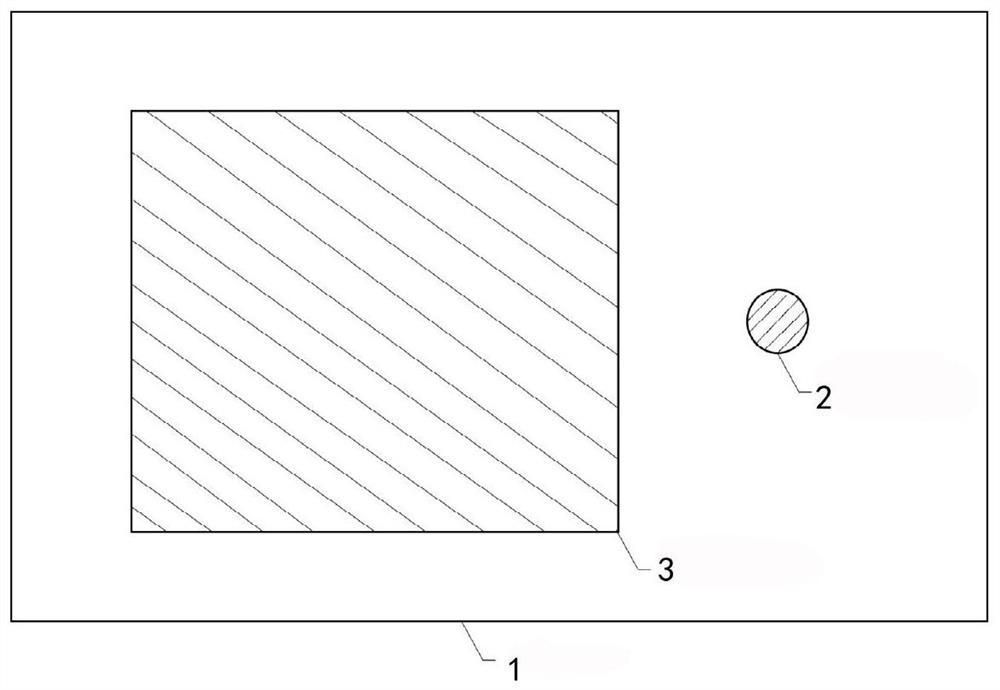

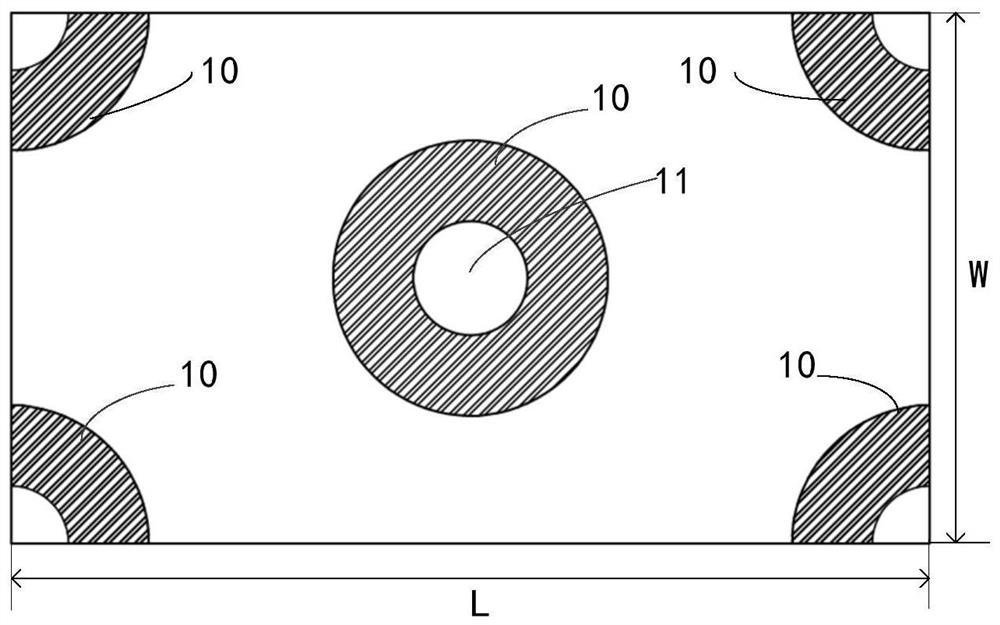

[0037] Embodiment 1: In this embodiment, the grating used in the optical waveguide is a hollow annular cylindrical grating, the inner diameter of each hollow annular cylindrical grating is 90nm, the outer diameter is 300nm, and the height is 100nm. period, see image 3 , a complete hollow annular cylindrical grating 10 is distributed in the middle, and a quarter of the hollow annular cylindrical grating 10 is distributed at the four corners. The long side dimension L of each grating period is 200nm-2μm, and the long side dimension L and the short side dimension The ratio of W is Also simulate the grating shown in this example, see figure 2 , arrange the grating periodically in the coupling-in region 2 and the coupling-out region 3 of the optical waveguide, so that the refractive index of the grating layer is 1.8, the forward order diffraction efficiency is 62.53%, the extended order diffraction efficiency is 8.35%, and The outcoupling order diffraction efficiency is 1.04%,...

Embodiment 2

[0038] Embodiment 2: In order to observe the change of the diffraction efficiency of the hollow annular cylindrical grating with different inner diameters, please refer to Figure 4 , we also provide a graph of the relationship between the inner radius of the grating structure and the diffraction efficiency. In this embodiment, the same grating structure as that shown in Embodiment 1 is that the outer diameter of each hollow annular cylindrical grating is 300nm and the height is 100nm, and in each grating period, please refer to image 3 , a complete hollow annular cylindrical grating 10 is distributed in the middle, and a quarter of the hollow annular cylindrical grating 10 is distributed at the four corners. The long side dimension L of each grating period is 200nm-2μm, and the long side dimension L and the short side dimension The ratio of W is The difference from the grating structure shown in Embodiment 1 is that in this embodiment, different optimizations are made to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com