Double-layer offset grating for 1×2 beam splitting of normal-incidence quartz with tm polarization

A technology of vertical incidence and grating, applied in diffraction grating and other directions, to achieve the effect of high diffraction efficiency, flexible and convenient use, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

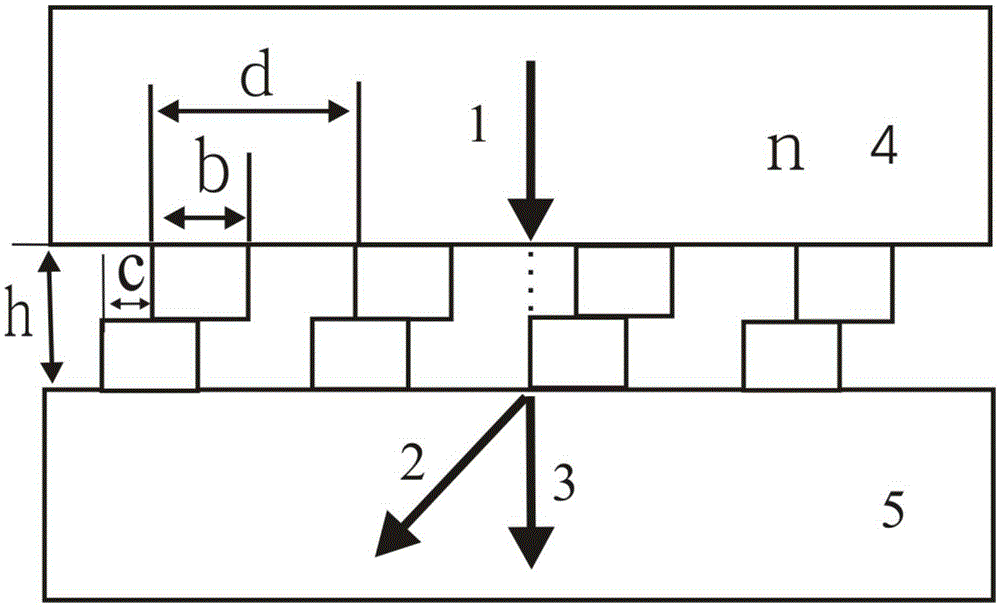

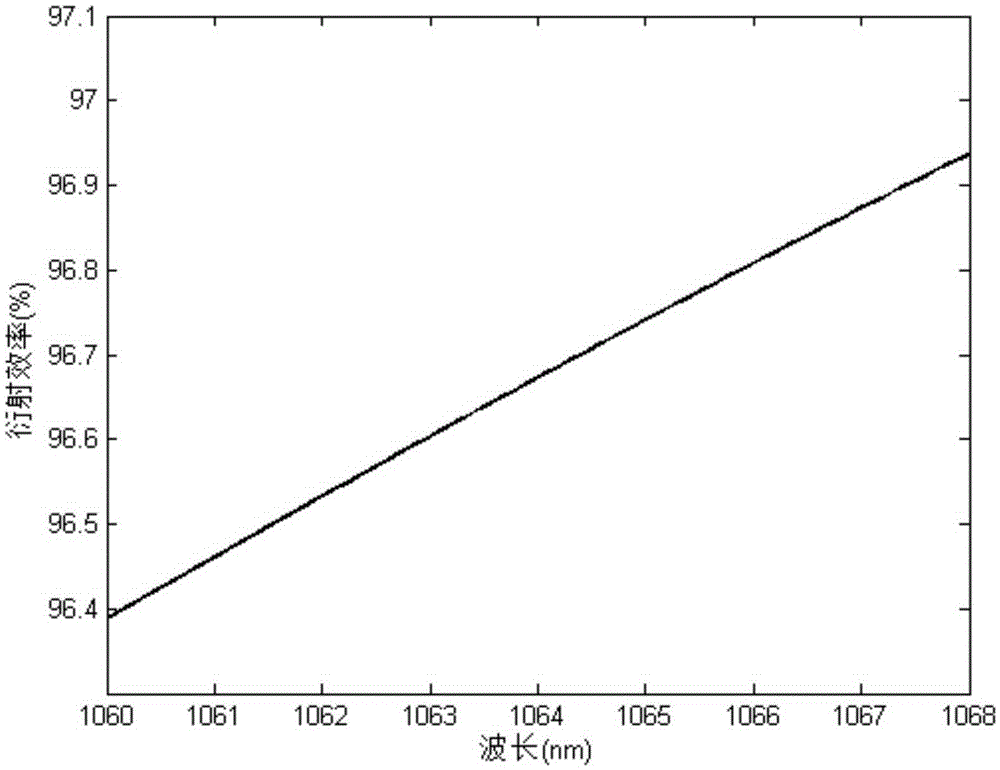

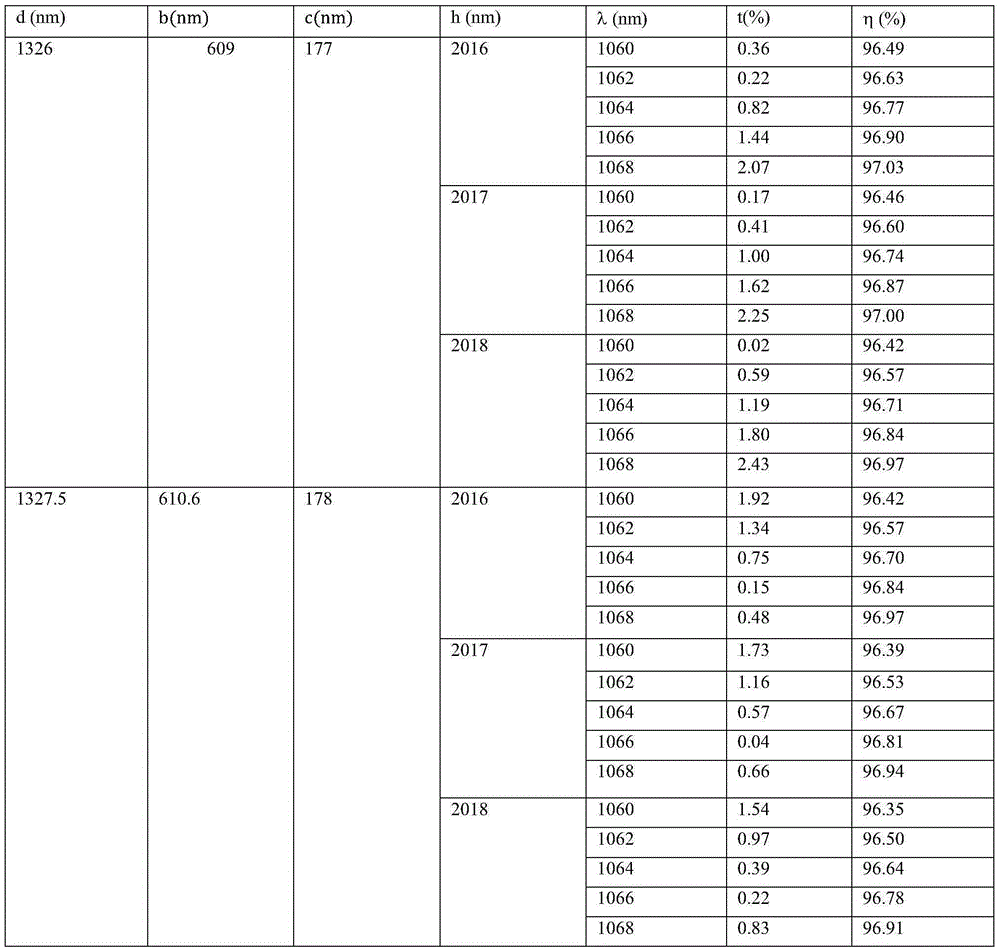

[0015] see first figure 1 , figure 1 It is the geometry structure of double-layer shifted grating for 1064 nanometer wavelength TM polarization of the present invention with vertical incidence quartz 1×2 beam splitting. In the figure, regions 4 and 5 are both fused silica (refractive index n=1.45). It can be seen from the figure that the present invention is a double-layer shifted grating for TM polarization with a wavelength of 1064 nanometers for vertical incidence quartz 1×2 beam splitting. The grating period of the grating is 1327.5 nanometers, and the offset is 178 nanometers. The ridge width is 610.6 nanometers, the total grating depth is 2017 nanometers, and the structure parameters of the upper and lower gratings are the same.

[0016] in such as figure 1 Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com