Vapor-water conversion type bubbler of nuclear power station

A technology for bubblers and nuclear power plants, applied in chemical instruments and methods, dissolving, mixing methods, etc., can solve problems such as high labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

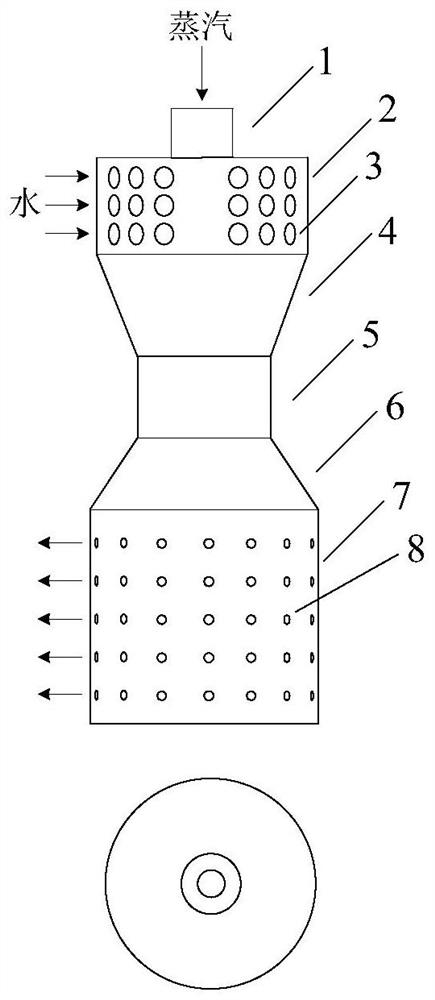

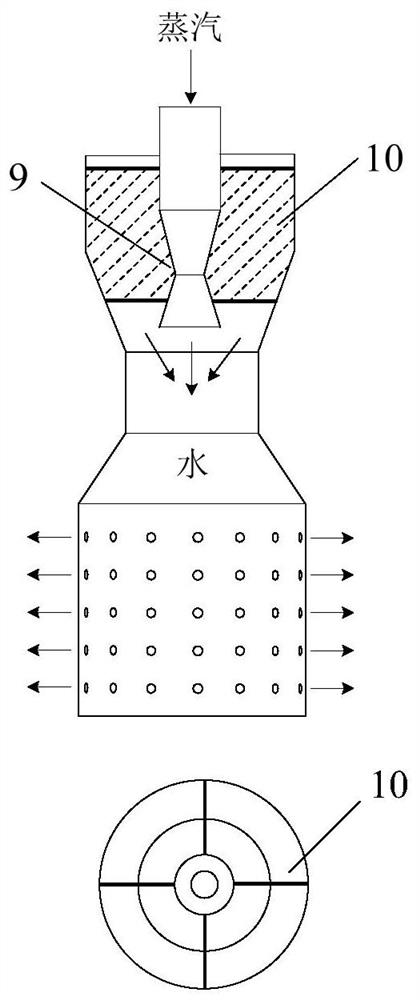

[0013] The steam-water conversion type bubbler of the nuclear power plant is usually set in the normal temperature water tank of the containment, submerged in water, and the pipeline of the pressure relief system is connected with the steam inlet pipeline of the bubbler. The steam-water conversion type bubbler itself mainly includes a steam inlet pipe, a water inlet chamber, a water inlet hole, a shrinkage chamber, a mixing chamber, a boost chamber, a bubble chamber, a bubble hole, a scaling nozzle and a support plate. During normal operation, when there is no steam discharge from the pressure relief system, the steam-water conversion type bubbler is filled with water. When the pressure relief system discharges steam, the steam is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com