Lifting appliance special for overhead turnover unloading of container

A container and spreader technology, applied in the direction of loading/unloading, transportation and packaging, load hanging components, etc., can solve the problems of long time, cargo damage and leakage, heavy environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

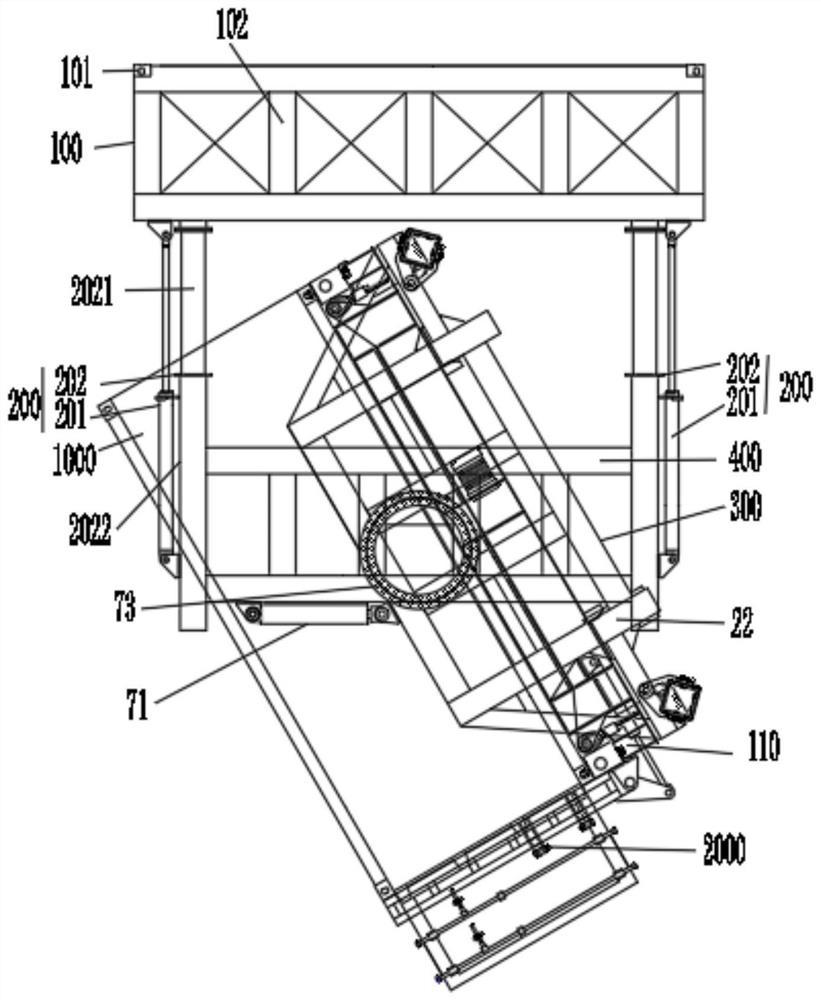

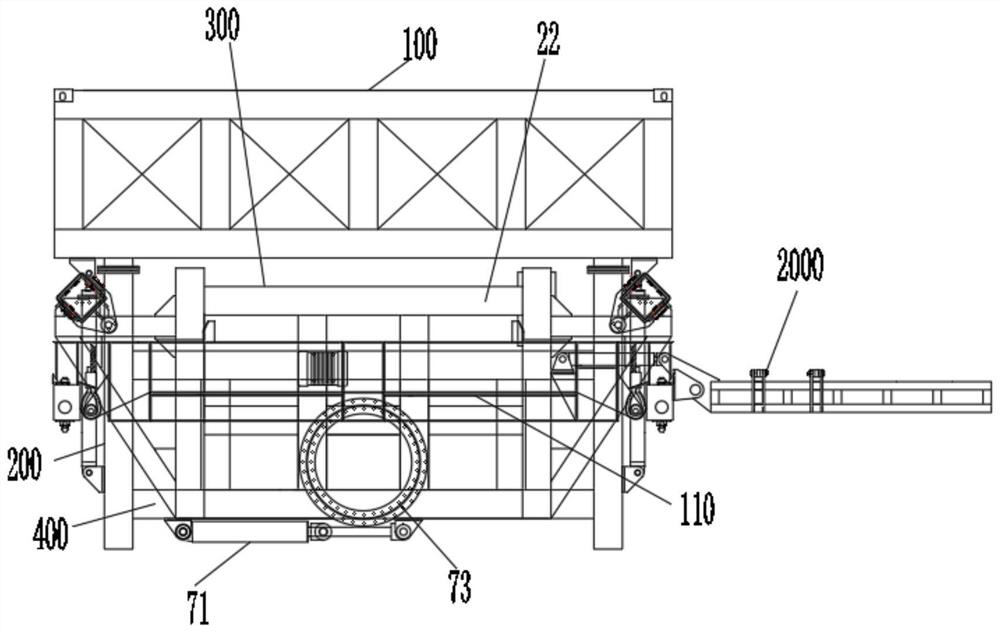

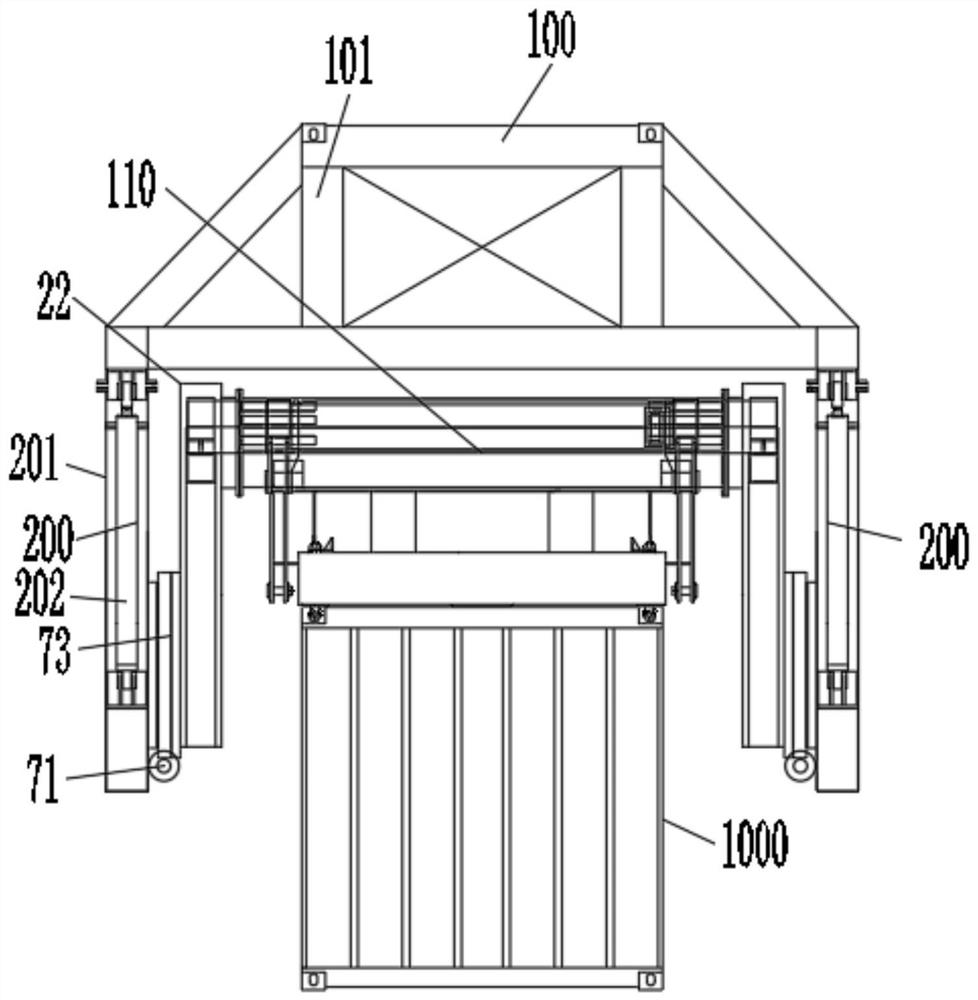

[0060] As shown in the accompanying drawings, the special spreader described in this embodiment includes a hoisting connector 100, a hoisting body 400 and a telescopic device 200, and the two ends of the telescopic device 200 are respectively connected to the hoisting connector 100 and The hoisting body 400 is connected, and the telescopic device 200 drives the distance between the hoisting connector 100 and the hoisting body 400 to increase or decrease. The hoisting body 400 is provided with an overturning mechanism 300 for hoisting containers, and the overturning mechanism 300 is used to overturn the hoisted container To the horizontal, vertical or inclined shape, the hoisting connection part 100 is provided with a hoisting connection part 101. Further, the telescopic device 200 includes a telescopic part 202 and a telescopic drive part 201 for driving the telescopic part to perform telescopic movements. The two parts of the telescopic part 202 The ends are respectively conne...

Embodiment 2

[0081] The general structure of the special spreader for container overturning and unloading in the air described in this embodiment is the same as that of Embodiment 1, but the only difference from Embodiment 1 is that the telescopic drive part includes a telescopic drive cylinder; the end of the outer pipe and the hoisting connector Fixedly connected, the cylinder body of the telescopic drive oil cylinder is connected to the inner pipe, and the telescopic rod is connected to the outer pipe or the hoisting connector, and the hoisting body is connected to the inner pipe. It makes the separating or closing action between the hoisting connecting piece and the hoisting body stable and reliable.

[0082] Based on the working principle of the above structure, the hanger of the hoisting equipment such as front crane and gantry crane is connected and fixed with the hoisting hole of the hoisting connector, and then the special spreader is positioned above the full container, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com