Single-groove double-needle faller, double-station flat knitting machine bottom plate, computerized flat knitting machine and knitting method

A double-station, needle-plate technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as the influence of machine head running stability, complex structure, and limited types of knitted fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

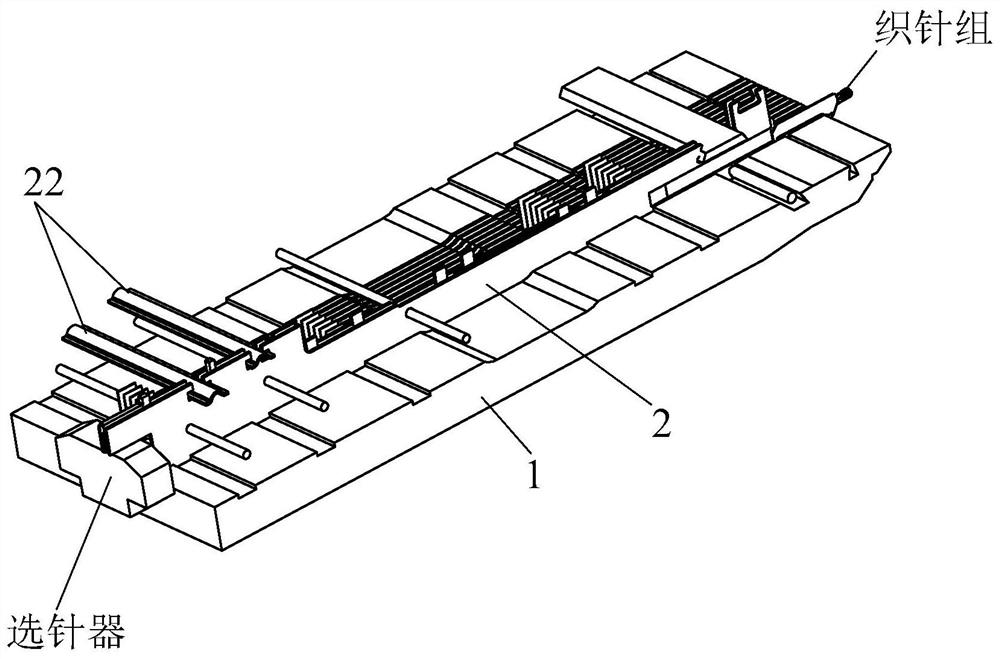

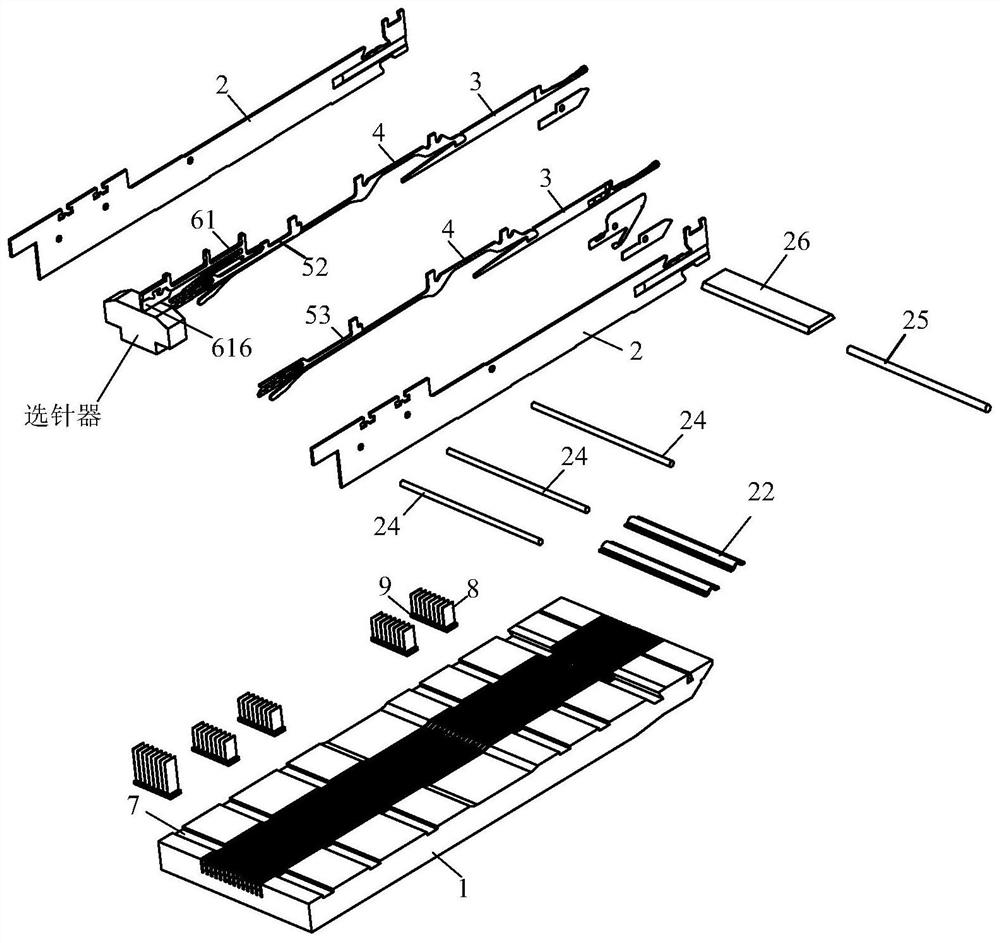

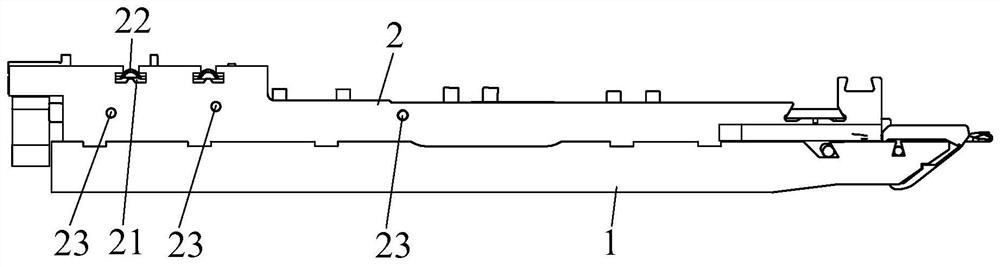

[0095] see Figure 1 to Figure 8 .

[0096] This embodiment 1 discloses a single-slot double-needle needle board, which includes a needle board main body 1. On the upper surface of the needle board main body 1, there are insert grooves that run through the front and rear ends of the needle board main body 1. 1 A row is arranged in the length direction, and a row of slots are parallel and equally spaced. Inserts 2 are inserted in the slots, and needle slots are formed between every two adjacent slots 2; two pin slots are placed in the slots. In the knitting needle group, the two knitting needle groups can carry out knitting work independently but not at the same time, so that the single-slot double-needle needle board device has the function and effect of upper and lower needle boards. In addition, the upper surface of the needle plate main body 1 is also provided with needle spacer installation grooves 7 that run through the left and right ends of the needle plate main body 1...

Embodiment 2

[0109] see Figure 9 .

[0110] This embodiment 2 discloses a double-station flat knitting machine base plate, including a triangular base plate A1, at least one knitting unit is arranged on the triangular base plate A1, when one knitting unit is set, it is a single-system base plate, and when multiple knitting units are set, it is a multi-system base plate , according to actual needs. Each knitting unit is equipped with two working positions, and the two working positions are arranged up and down. Each working position can protrude from the triangular base plate A1 to press the needle or retract into the triangular base plate A1 to release the pressing needle under the power drive. The woven sheet A2, the left stitch sheet A3, the tuck sheet A4, the right stitch sheet A5 and the non-woven sheet A6. The braided sheet A2 is located above the non-woven sheet A6, and the left needle sheet A3, the tuck sheet A4, and the right needle sheet A5 are arranged in sequence from left to...

Embodiment 3

[0117] see Figure 10 .

[0118] The difference between the double-station flat knitting machine base plate disclosed in Embodiment 3 and the double-station flat knitting machine base plate disclosed in Embodiment 2 is that in Embodiment 3, neither of the two working positions configured by each knitting unit Contains braided tabs. Other structures are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com