Damping adjusting system for flexible wind turbine generator system tower and wind turbine generator system

A technology of damping adjustment and wind turbines, which is applied to the installation/supporting of wind turbines, wind power generation, towers, etc., and can solve problems such as difficult installation, reduced service life of towers, and increased weight of towers and nacelles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

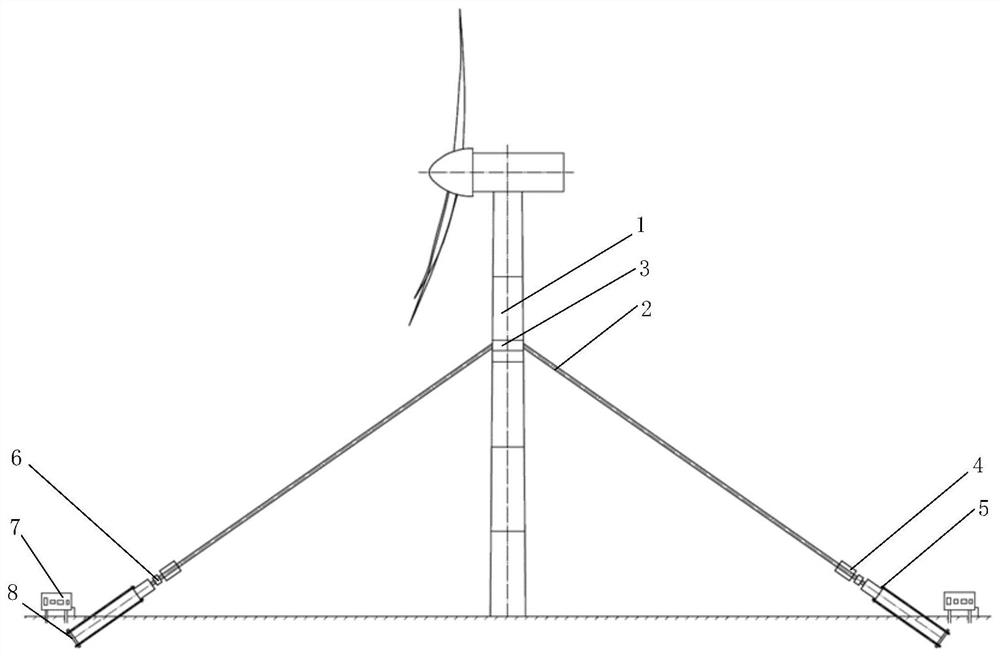

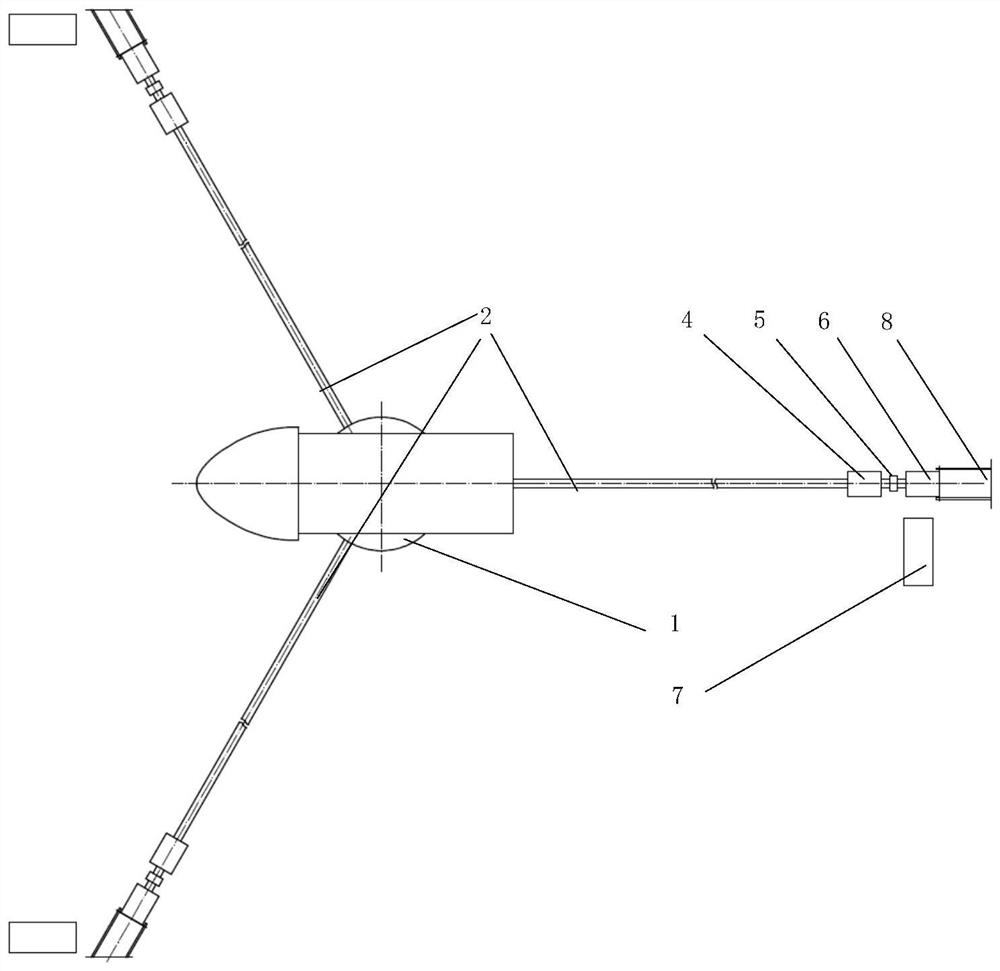

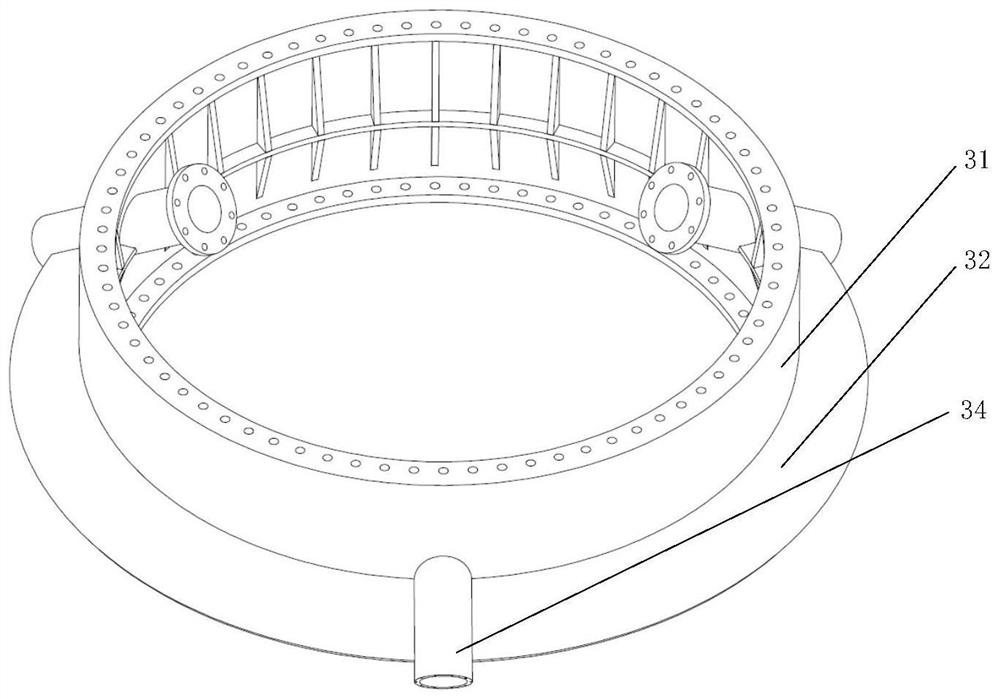

[0055] Such as figure 1 , figure 2 As shown, the present invention adopts a cable-stayed land flexible wind turbine tower and its damping adjustment system, including a wind turbine tower 1, cable stays 2, cable fixing devices 3 on the tower, and cable fixing devices at the bottom of the tower. A device 4, a damping adjustment device 5 and a sensor 6 connected thereto, a control module 7 and an anchoring device 8. The stay cable fixing device 3 on the tower is connected with the wind turbine tower 1 through high-strength bolts, and a plurality of stay cables 2 are arranged at a symmetrical angle to the center line of the wind turbine tower 1. Each stay cable 2 and the tower bottom stay cable The fixing device 4, the damping adjusting device 5 and the connected sensor 6, the control module 7 and the anchoring device 8 constitute a basic unit of the damping adjusting system, which is connected to a specific position of the cable fixing device 3 on the tower. Wherein, one end ...

Embodiment 2

[0070] The difference between this embodiment and Embodiment 1 is that in this embodiment, the sensor is a displacement sensor, which is arranged on the end face of the damper bracket, and the position signal is used as the damping adjustment control signal in the control module.

[0071] Such as Figure 10 As shown, the tower bottom cable fixing device 4 in Embodiment 2 of the present invention includes a rainproof cover 41, a cable sleeve 42, a shock absorbing ring 43, a cable clamp 44, an anchor cup 45, a sealing cover 46, a lock nut 47, and an anchor Tool 48, protective cover 49. The cable sleeve 42 is provided with a damping ring 43 for reducing the vibration of the cable, a cable clamp 44 and an anchor cup 45 for fixing the internal steel wire of the cable, and the cable stay 2 passes through the rain cover 41, The shock absorbing ring 43, the cable clamp 44, the seal cover 46 and the annular hole of the anchor cup 45 are axially fixed by the lock nut 47, and the anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com