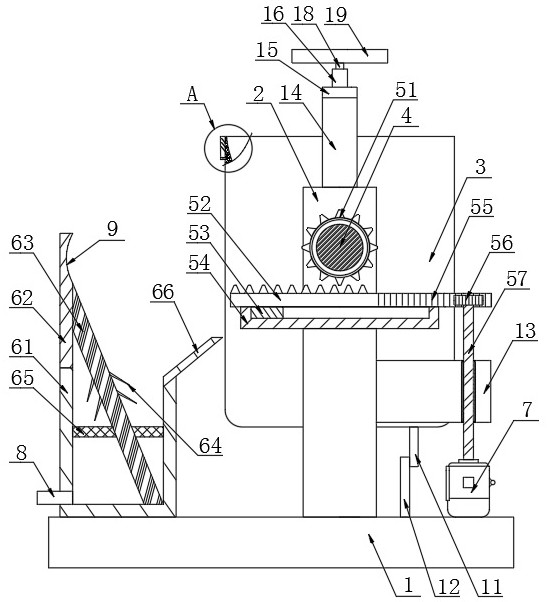

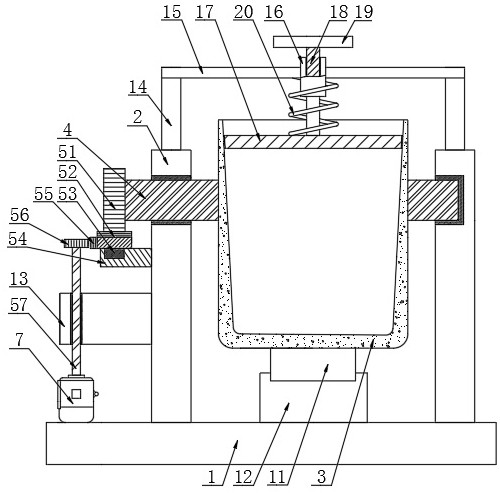

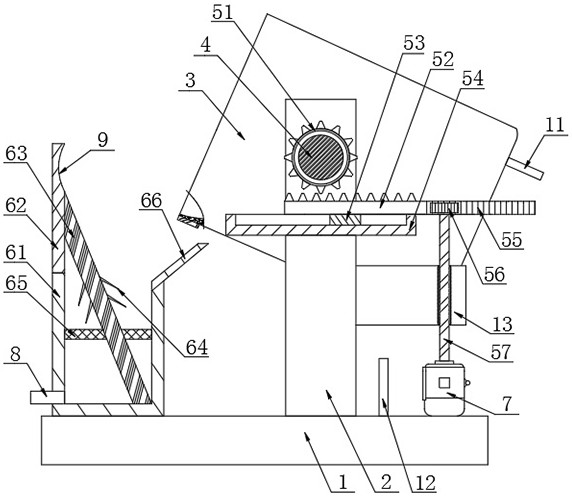

Easy pouring and splash-proof melting furnace

An anti-splash, melting furnace technology, applied in furnace safety devices, furnaces, crucible furnaces, etc., can solve problems such as furnace wall damage, melting furnace slippage, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] The embodiment is specifically: when the furnace body 3 is tilted with the rotation of the output end of the motor 7, the molten metal inside the furnace body 3 flows out through the flow limiting groove 10, and at this time the limiting plate 62 can limit the poured molten metal, Make it fall into the inside of the buffer barrel 61 accurately, and at the same time, the drainage column 63 can drain the poured molten metal, so that it can smoothly fall into the interior of the buffer barrel 61 along the drainage column 63, preventing the molten metal from entering the buffer barrel 61. The phenomenon of splashing occurs, and the restrictor plate 64 can prevent the metal liquid inside the buffer tank 61 from flowing back along the drainage column 63 when the poured liquid is too much, and the buffer net 65 can reduce the impact of the metal liquid on the buffer tank 61 The impact force reduces its fluctuation inside the buffer barrel 61 and prevents it from splashing again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com