Thermal analysis method for testing volatile and oxidizable alloy material by using nested sealed crucible

A nested and reused technology, applied in the field of analysis and testing, which can solve problems such as pollution and large error in measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

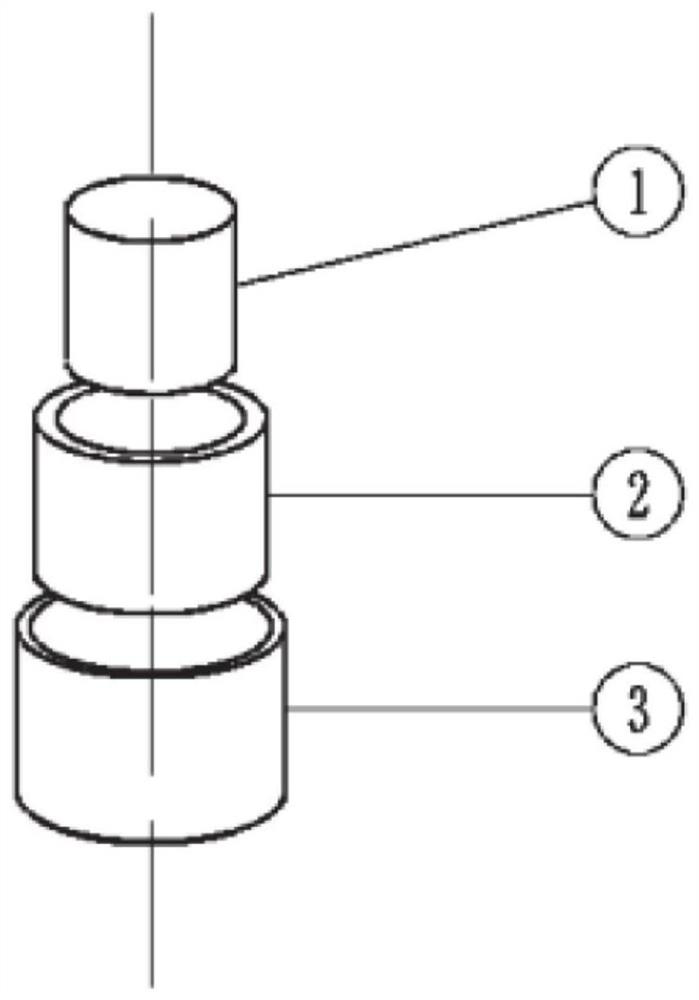

[0033] A reusable nested sealed crucible, comprising: inner and outer crucibles 1, 3, and a sealing gasket 2; the sealing gasket 2 is in the shape of a barrel, and the inner and outer crucibles 1, 3 and the sealing gasket 2 Use interference fit to form a sealed space.

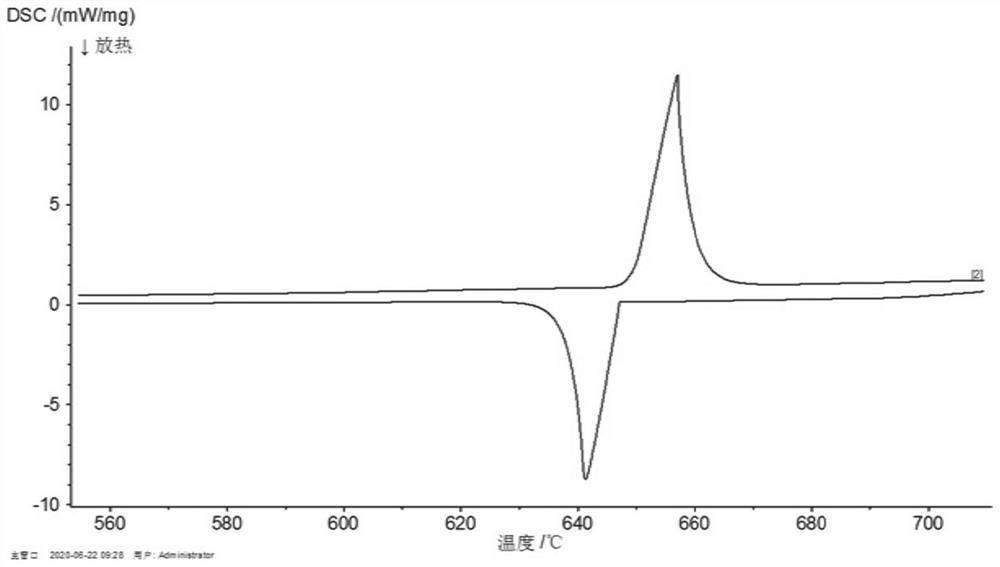

[0034] Pure magnesium DSC, specific tests include:

[0035] First, the above-mentioned inner and outer crucibles and sealing gaskets are sealed to form a reference crucible, and the quality of the reference crucible is weighed; the quality of the inner and outer crucibles and sealing gaskets, and the quality of the pure magnesium sample are weighed, and then sealed to form a sample crucible; The reference crucible and sample are placed on the thermal analysis equipment support;

[0036] Then set up the test program, Name the test result file; open the purge gas and start measurement; open the test result file and output the test result, see figure 2 .

[0037] Finally, take out the experimental crucible a...

Embodiment 2

[0039] Magnesium-aluminum-zinc alloy thermal analysis, the crucible that adopts is the same as embodiment 1, and concrete test comprises:

[0040] First, seal the inner and outer crucibles and sealing gaskets to form a reference crucible, weigh the quality of the reference crucible; weigh the quality of the inner and outer crucibles and sealing gaskets, and the quality of the pure magnesium sample, and then seal to form a sample crucible; The crucible and sample are placed on the thermal analysis equipment support;

[0041] Then set up the test program, Name the test result file; open the purge gas to start measurement; open the test result file to output the test result.

[0042] Finally, take out the experimental crucible and wait for cleaning.

Embodiment 3

[0044] AZ31 alloy thermal analysis, the crucible that adopts is with embodiment 1, and concrete test comprises:

[0045] First, seal the inner and outer crucibles and sealing gaskets to form a reference crucible, weigh the quality of the reference crucible; weigh the quality of the inner and outer crucibles and sealing gaskets, and the quality of the pure magnesium sample, and then seal to form a sample crucible; The crucible and sample are placed on the thermal analysis equipment support;

[0046]Then set up the test program, Name the test result file; open the purge gas to start measurement; open the test result file to output the test result.

[0047] Finally, take out the experimental crucible and wait for cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com