Rotor and surface-magnet-type rotating electrical machine

A technology of rotor core and rotor is applied in the field of rotor and surface magnet type rotating electrical machine, which can solve the problems of reducing centrifugal force and reducing the holding strength of permanent magnet, and achieve the effect of suppressing falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] (Surface magnet type rotating electrical machines)

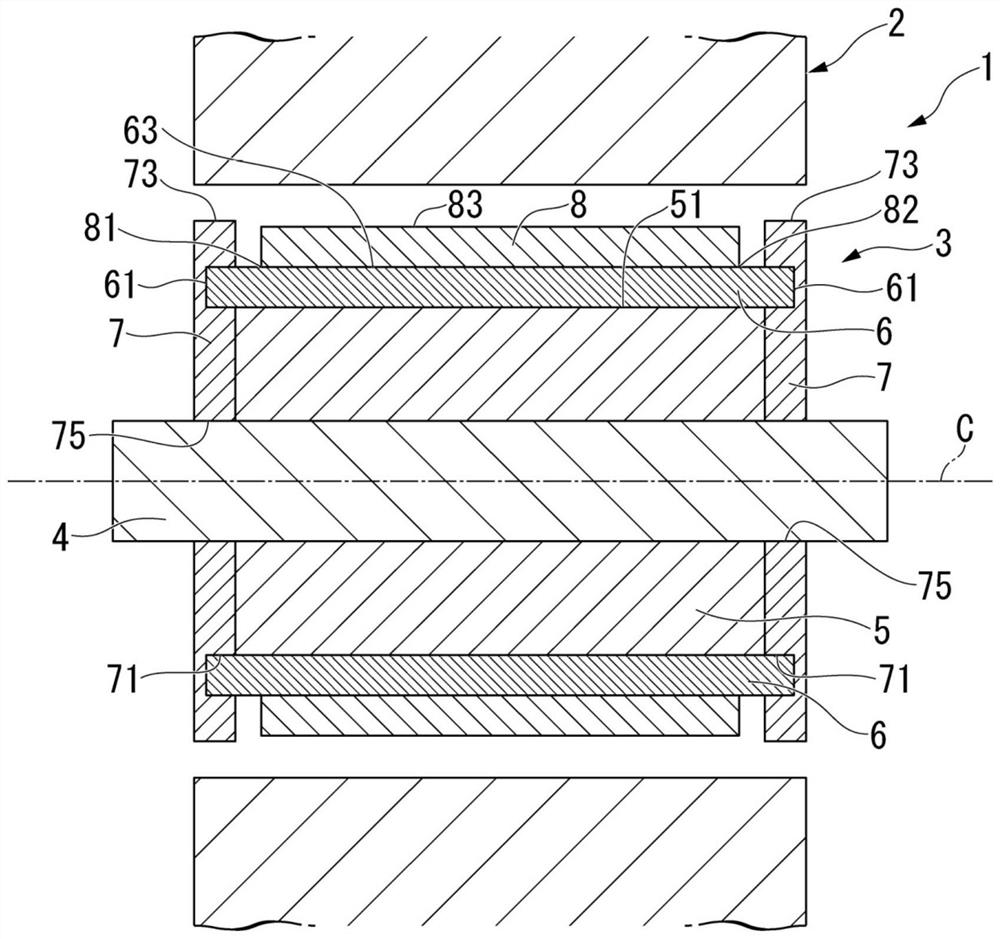

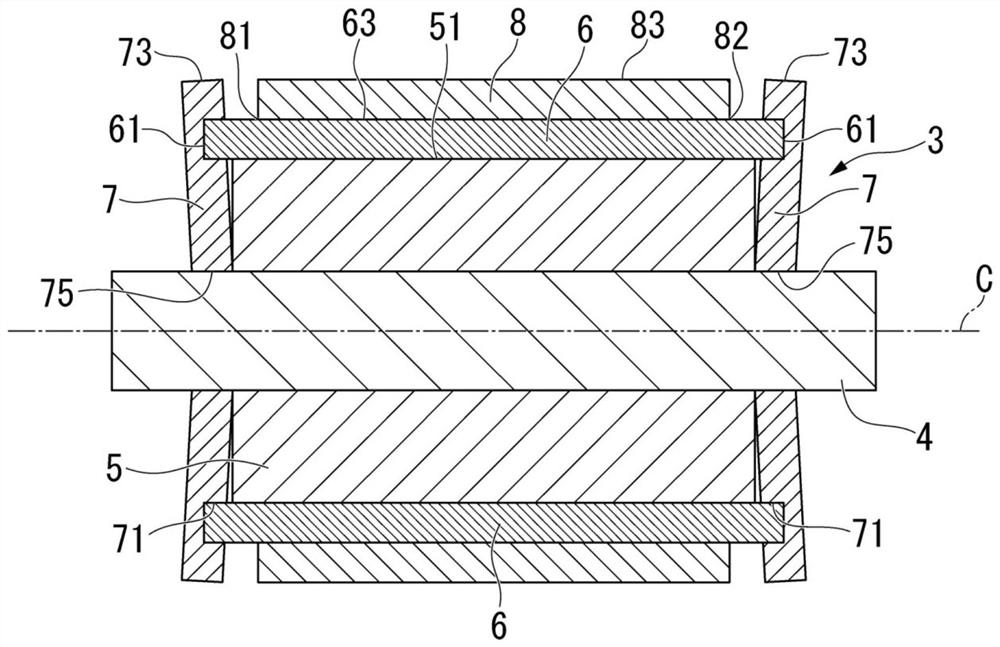

[0043] figure 1 It is a sectional view of the surface magnet type rotating electrical machine 1 of the embodiment.

[0044] The surface magnet type rotating electrical machine 1 is, for example, a running motor mounted in a vehicle such as a hybrid vehicle or an electric vehicle. However, the configuration of the present invention is not limited to a travel motor, and can be applied to a motor for power generation, a motor for other purposes, and a rotating electric machine (including a generator) other than for vehicles. The surface magnet type rotating electrical machine 1 is a so-called SPM (Surface Permanent Magnet) motor in which a permanent magnet 6 is arranged on an outer peripheral surface 51 of a rotor core 5 .

[0045] A surface magnet type rotating electrical machine 1 includes a stator 2 and a rotor 3 .

[0046] The stator 2 is formed in an annular shape with the axis C as the center. The stator 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com