Mud removal equipment for industrial wastewater treatment

A technology for industrial waste water and equipment, applied in filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of sludge pollution, corrosion, incomplete sludge removal, equipment damage, etc., and improve the sludge removal effect. , Avoid corrosive damage, reduce the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

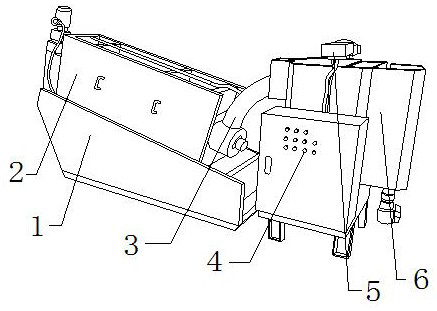

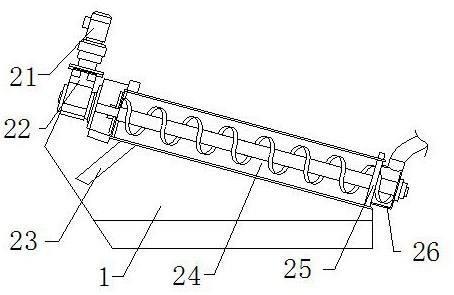

[0024] Such as Figure 1-Figure 4 Shown:

[0025] The present invention provides a desilting equipment for industrial wastewater treatment, the structure of which includes a fixed seat 1, a desilter 2, a mud inlet pipe 3, a control electric box 4, an extractor 5, and a storage box 6. The extractor 5 and the control The electrical box 4 is electrically connected, the storage box 6 is connected to the desilter 2 through the mud inlet pipe 3, the extractor 5 is bolted to the top of the storage box 6, and the mud inlet pipe 3 is nested and connected to the desilter The side of the machine 2, the desilter 2 is embedded and connected to the top of the fixed seat 1, and the desilter 2 mainly includes a motor 21, a rotator 22, a dumping plate 23, a desilter device 24, an isolation plate 25, a temporary Storage box 26, the motor 21 is mechanically connected to the top of the rotor 22, the desilter device 24 is nested and connected to the side of the rotor 22, and the temporary storage...

Embodiment 2

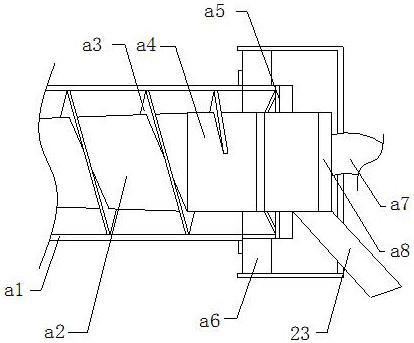

[0031] Such as Figure 5-Figure 7 Shown:

[0032] The present invention provides a desilting equipment for industrial wastewater treatment, the structure of which includes a fixed seat 1, a desilter 2, a mud inlet pipe 3, a control electric box 4, an extractor 5, and a storage box 6. The extractor 5 and the control The electrical box 4 is electrically connected, the storage box 6 is connected to the desilter 2 through the mud inlet pipe 3, the extractor 5 is bolted to the top of the storage box 6, and the mud inlet pipe 3 is nested and connected to the desilter The side of the machine 2, the desilter 2 is embedded and connected to the top of the fixed seat 1, and the desilter 2 mainly includes a motor 21, a rotator 22, a dumping plate 23, a desilter device 24, an isolation plate 25, a temporary Storage box 26, the motor 21 is mechanically connected to the top of the rotor 22, the desilter device 24 is nested and connected to the side of the rotor 22, and the temporary storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com