A kind of sesame grain classification and cleaning system and method based on positive and negative pressure separation

A classification system, positive and negative pressure technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc., can solve problems such as rapid separation of sesame seeds, and achieve automatic grain classification and work efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

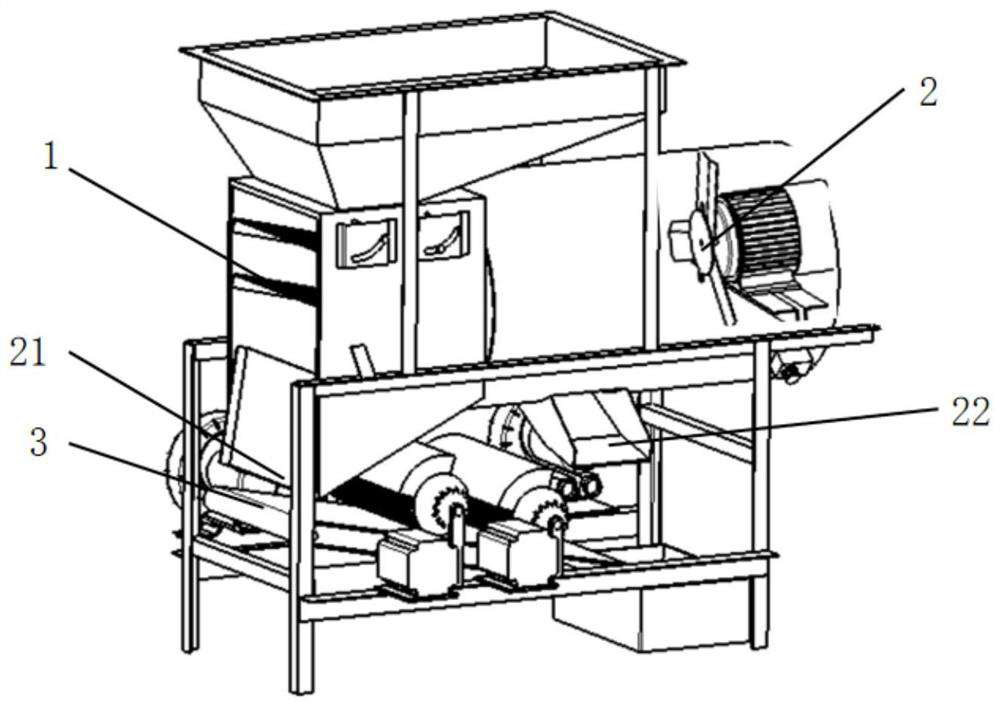

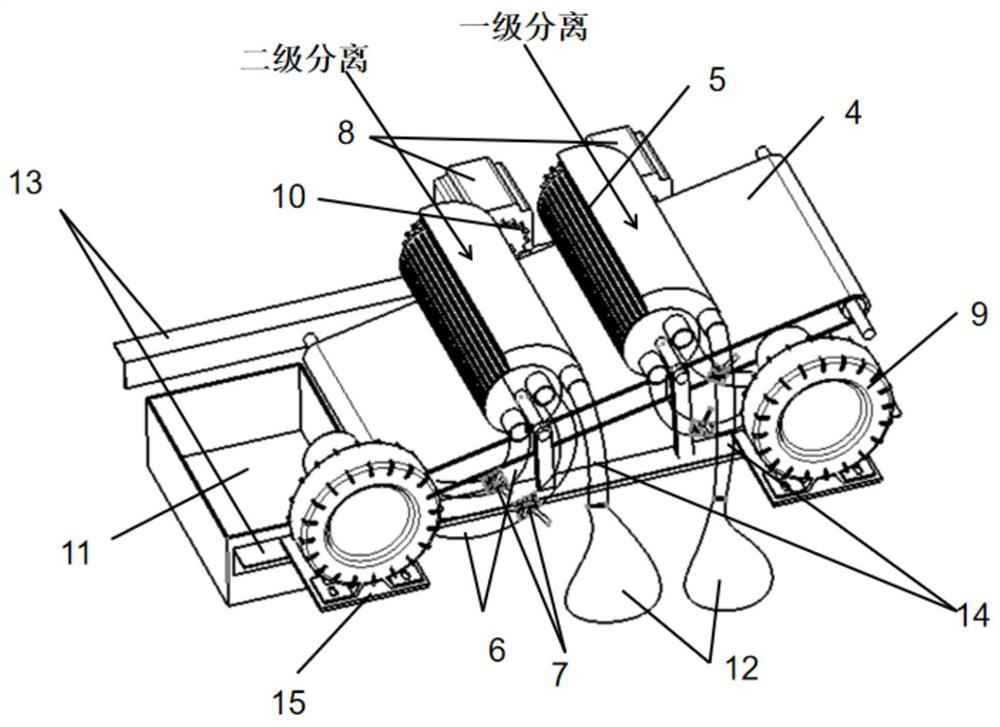

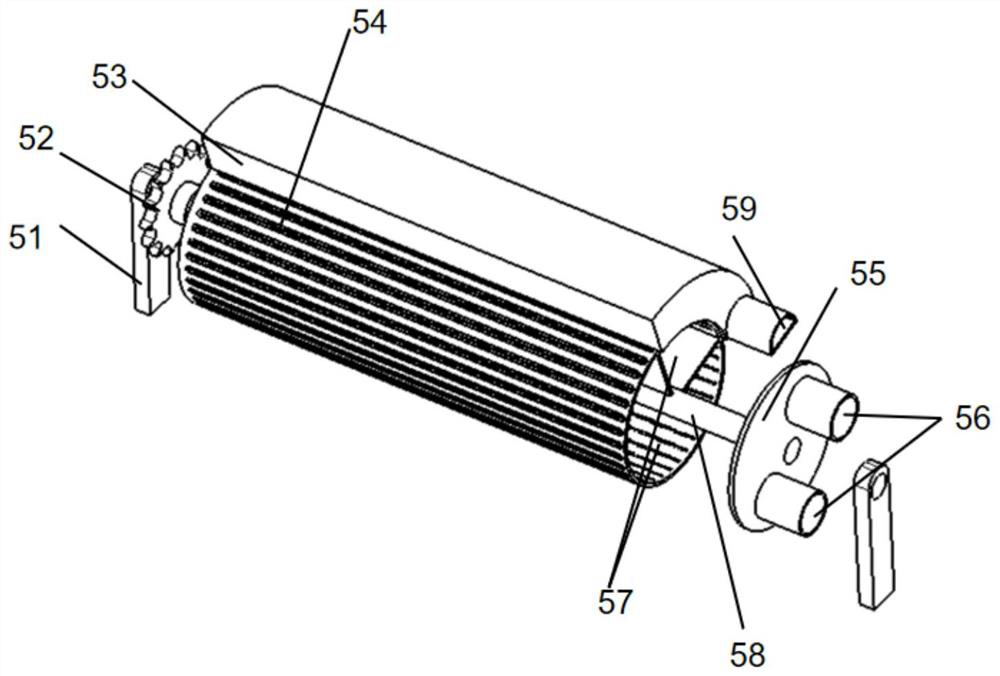

[0033] like Figure 1-4 As shown, the cleaning and grading device for sesame seeds in this embodiment includes a screening system (1), an impurity removal system (2) and a grading system (3).

[0034] The screening system (1) includes a hopper and at least one layer of filter screens, the hopper is arranged above the filter screen, the sesame seeds to be screened are poured into the entire cleaning and grading device from the hopper, and the filter screen is located below the hopper, and the aperture of the filter screen is larger than The particle size of the sesame seeds is so that the sesame seeds can pass through the filter sieve, and the larger impurities roll off, shake off or be blown off from the side of the filter sieve, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com