Double-spindle core-moving type numerical control lathe

A CNC lathe and dual-spindle technology, which is applied in the field of lathes, can solve problems such as affecting the shape of the workpiece and the jamming of the tool movement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

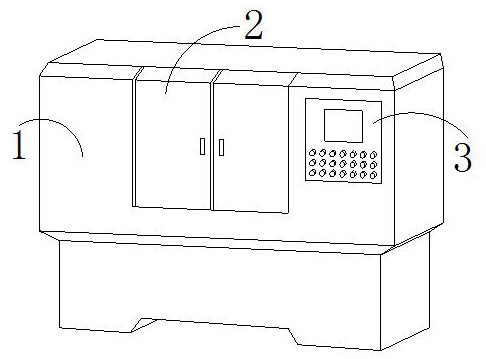

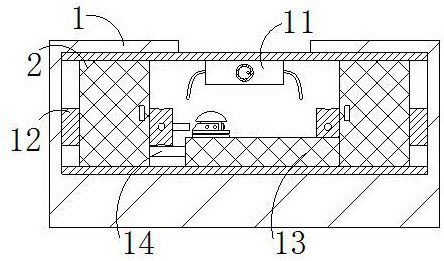

[0029] The present invention provides a dual-spindle core-moving CNC lathe, the structure of which includes a lathe 1, a protective door 2, and a control panel 3. The protective door 2 is connected to the front side of the lathe 1 through movable engagement, and the control panel 3 is embedded. On the front surface of the lathe 1, the lathe 1 includes a coolant tank 11, a main shaft 12, a support block 13, and a rotating shaft 14. The top of the coolant tank 11 is fixed on the upper inner wall of the lathe 1, and the main shaft 12 is engaged by a movable Connected to the left and right inner walls of the lathe 1, the support block 13 is installed at the bottom of the lathe 1, the right end of the rotating shaft 14 is connected to the left side of the support block 13 through a gap, the main shaft 12 has two, and the rotating shaft 14 is connected with the motor, and The cooling pipes at both ends of the coolant tank 11 can be raised and contracted, which is beneficial to the ro...

Embodiment 2

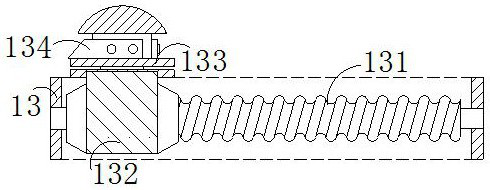

[0035]In the figure, the guide block a2 includes a limiting cavity a21, a temporary storage groove a22, an air bag a23, and a brush plate a24. The limiting cavity a21 is embedded in the guide block a2, and the temporary storage groove a22 and the guide block a2 The upper surface is an integrated structure, the airbag a23 is embedded in the bottom of the guide block a2, the brush plate a24 runs through the bottom of the guide block a2 and the top of the brush plate a24 is welded to the bottom of the fixed rod a1, and the temporary storage groove a22 faces inward Concave, and the brush plate a24 is made of rubber material and bends to the left at the same time, which is beneficial for the brush plate a24 to wipe the surface of the moving shaft 131 when the positioning block 132 moves, and avoids jamming when the positioning block 132 moves.

[0036] In the figure, the temporary storage groove a22 includes a guide plate m1, a bump m2, and a limiting block m3, the guide plate m1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com