Cutting machine with efficient heat dissipation function

A cutting machine, high-efficiency technology, applied in the direction of mechanical equipment, metal sawing equipment, sawing machine accessories, etc., can solve the problems of ignoring bearing cooling, easy expansion and deformation, high temperature of main shaft and bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

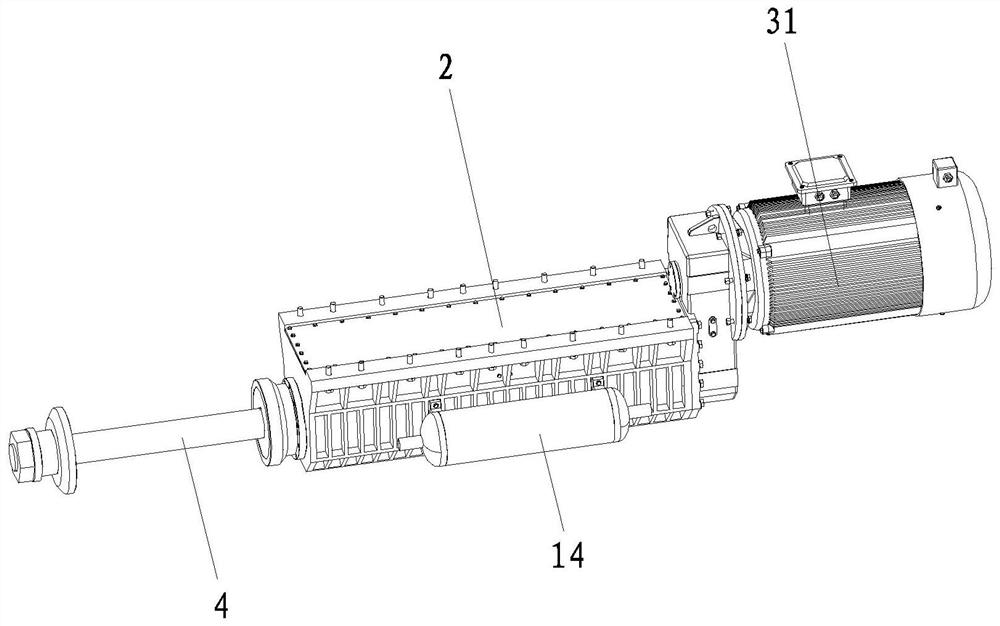

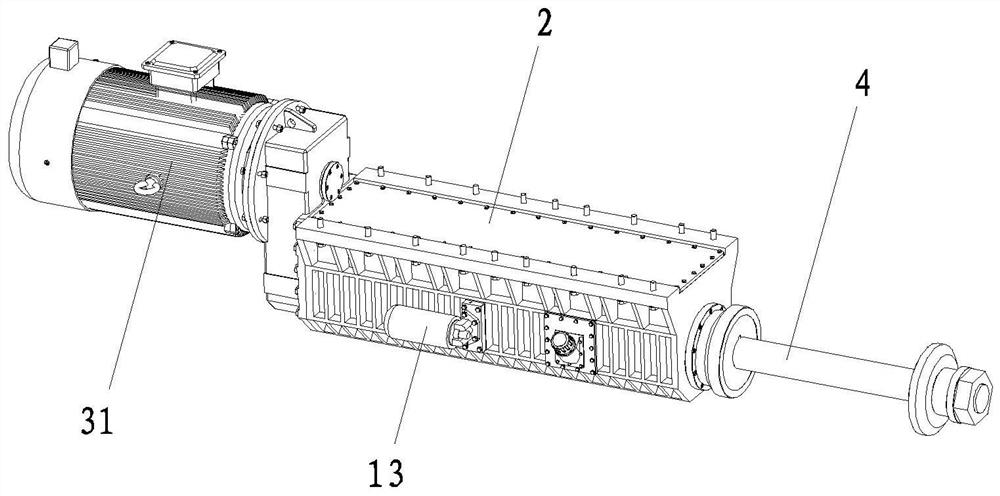

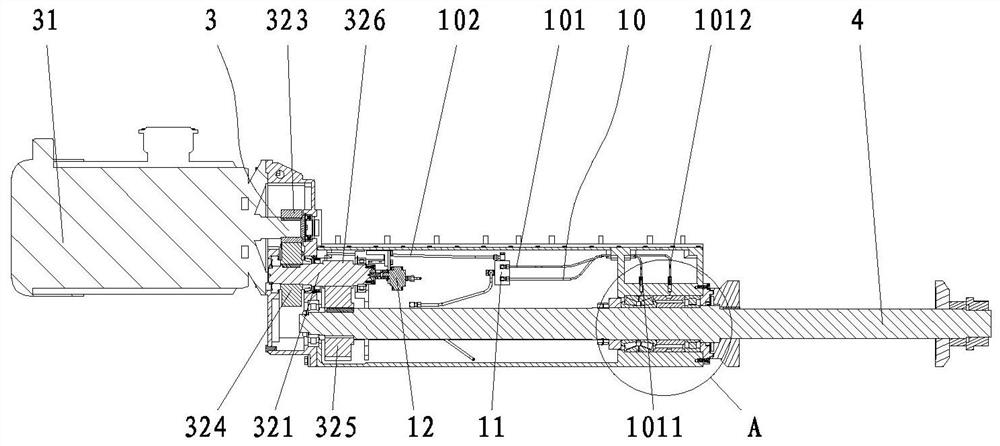

[0098] Such as Figure 1-7 As shown, a high-efficiency heat dissipation cutting machine includes a cutting machine main body; wherein, it also includes a heat dissipation device for cooling the main shaft 4 bearing of the cutting machine main body through flowing coolant. The heat dissipation device includes a cooling liquid delivery pipe for delivering cooling liquid to the heat-generating parts of the main body of the cutting machine; the cooling liquid delivery pipe includes more than two shunt pipes 10 corresponding to two or more heat-generating parts for cooling. The distribution pipe 10 is equipped with a valve (not shown) that matches the cooling liquid flow rate according to the heat generated by the heat-generating part. In this embodiment, the valve can be an adjustable solenoid valve.

[0099] Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com