PVC board embossing system and use method thereof

A technology of embossing and sheet metal, applied in other home appliances, applications, home appliances, etc., can solve the problems of low production efficiency, complex structure and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

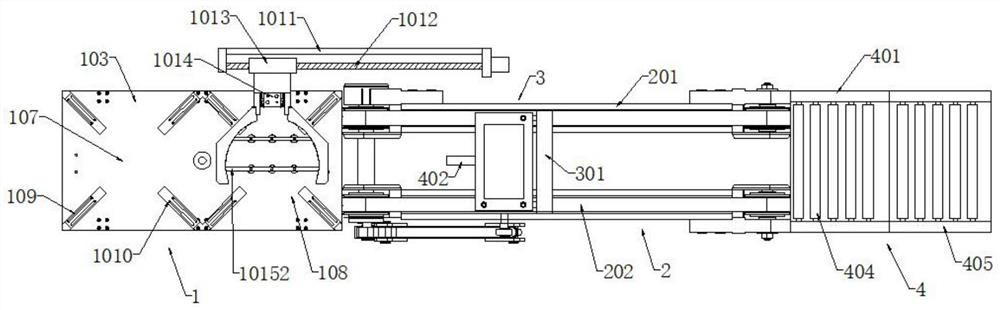

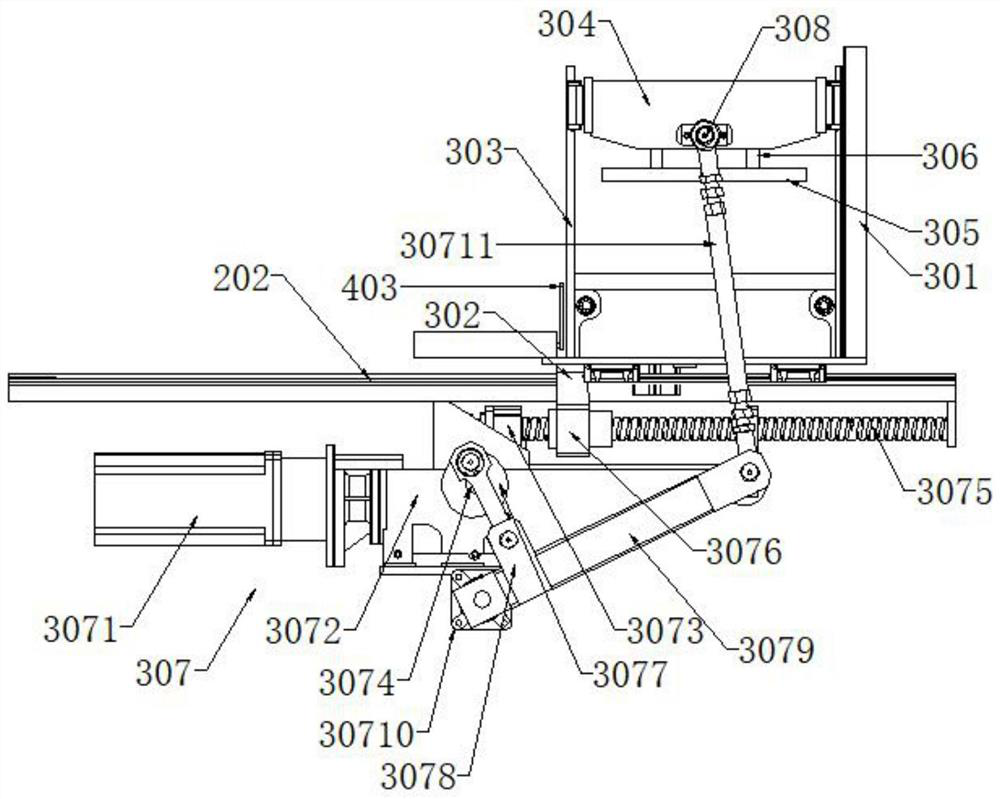

[0024] Examples, see attached Figure 1-5 , a kind of embossing system of PVC sheet material, comprises feeding device 1, feeding mechanism 2, embossing mechanism 3 and unloading device 4, and feeding device 1 is positioned at the left end of feeding mechanism 2, and feeding device 1 and feeding mechanism 2 They match each other. The feeding device 1 uses a vacuum suction cup 10154 for feeding. There are two sets of feeding stations, one feeding and one feeding, which greatly increases the efficiency of feeding. The embossing mechanism 3 is located in the feeding mechanism 2 above, and the embossing mechanism 3 is slidingly arranged on the feeding mechanism 2, the embossing mechanism 3 and the feeding mechanism 2 move synchronously, which improves the accuracy of embossing, the unloading device 4 is located at the right end of the feeding mechanism 2, and the unloading The device 4 and the feeding mechanism 2 match each other;

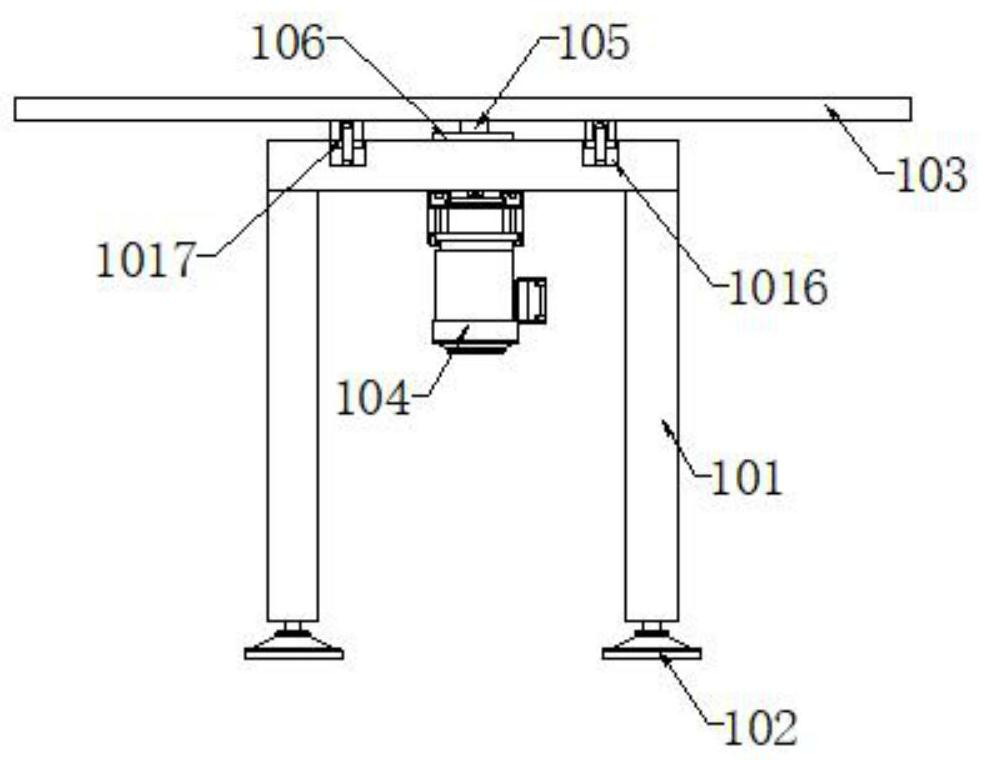

[0025] The feeding device 1 includes a support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com