Composite material vehicle door including outer water cutting windowsill beam

A composite material and external water cutting technology, which is applied in the automotive field, can solve the problems of difficulty in reducing the weight of the whole vehicle, and simplifying the assembly of diverse shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

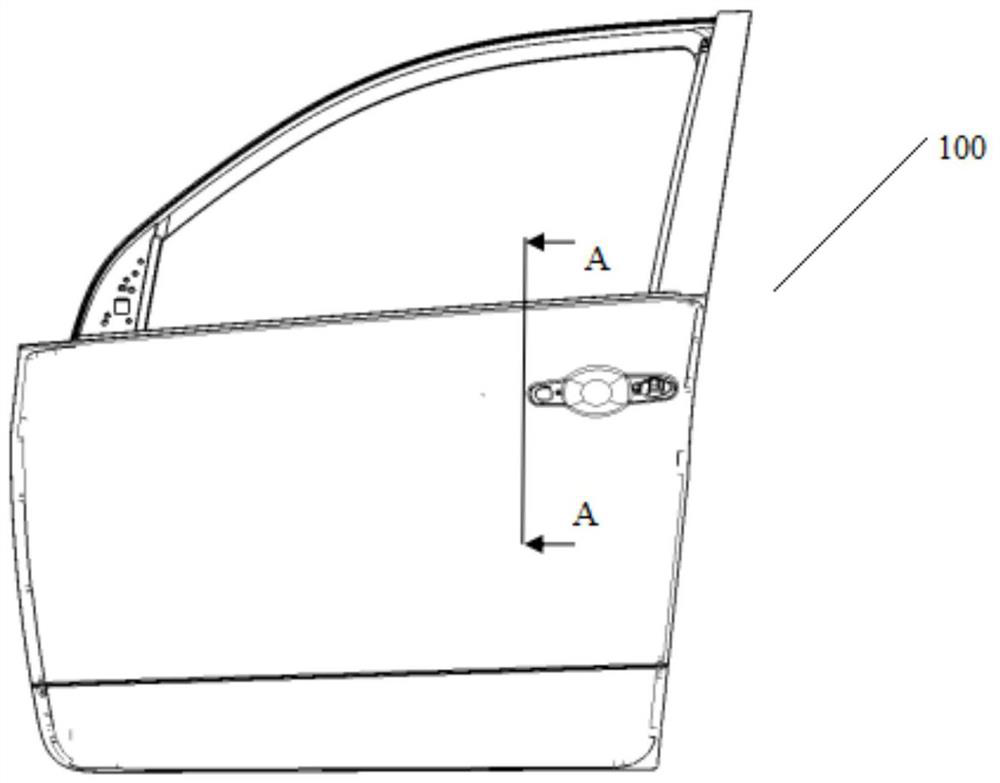

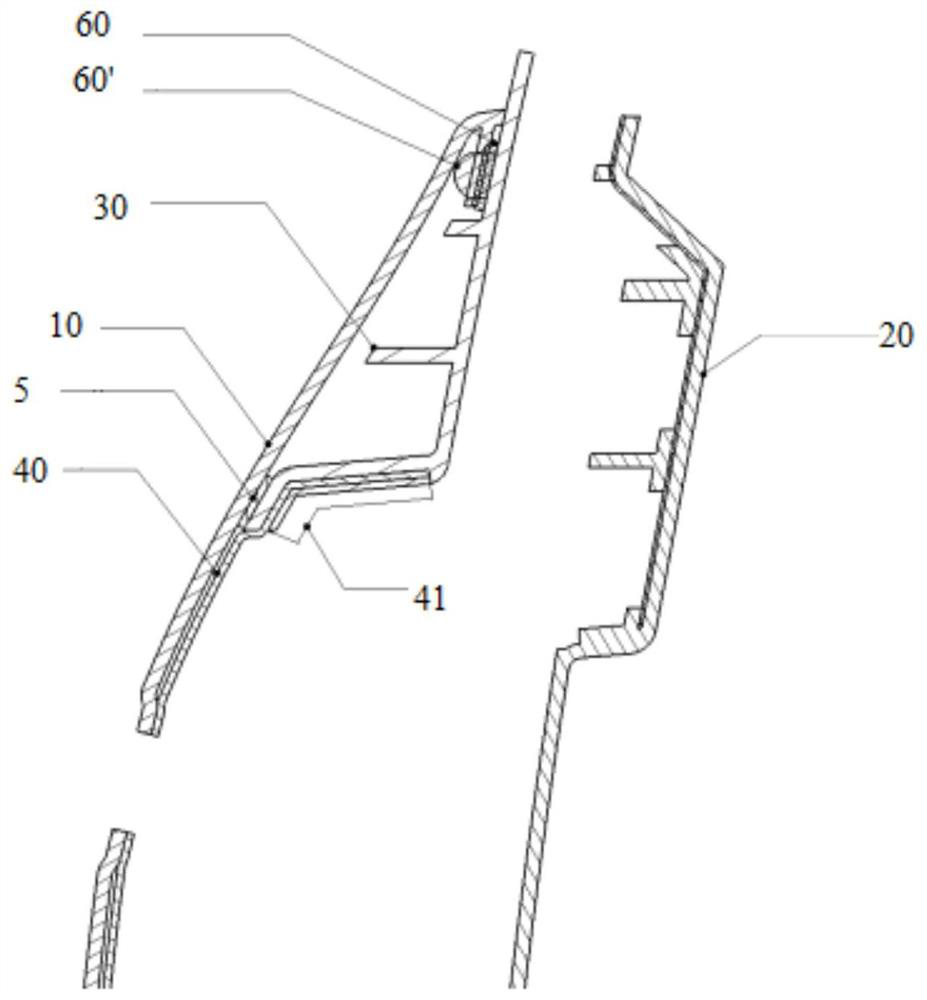

[0032] combine Figure 1 ~ Figure 2 As shown, a composite material car door 100 provided according to a preferred embodiment of the present invention mainly includes: a composite material car door outer panel 10, a composite material car door inner panel 20, an outer water cut window sill beam 30, and a car door outer handle reinforcement plate 40 . Wherein, the door outer handle reinforcement plate 40 is connected with the outer water-cut sill beam 30 , and is jointly arranged between the composite material vehicle door outer panel 10 and the composite material vehicle door inner panel 20 .

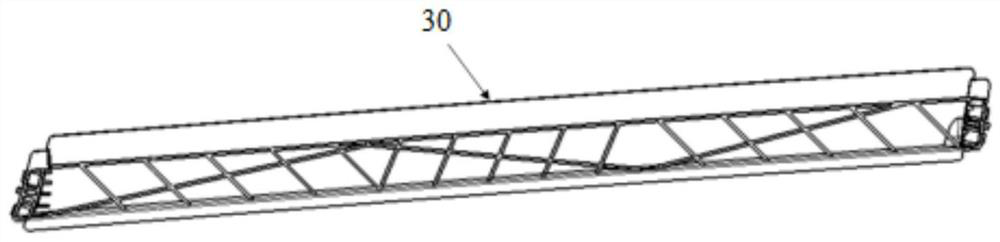

[0033] combine Figure 3 ~ Figure 4A As shown, the outer water-cut sill beam 30 includes: the outer water-cut sill beam body 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com