System for automatically separating, inspecting, marking and sub-packaging textile cut pieces and process

A technology for automatic separation and textiles, applied in paper product packaging, packaging automatic control, packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

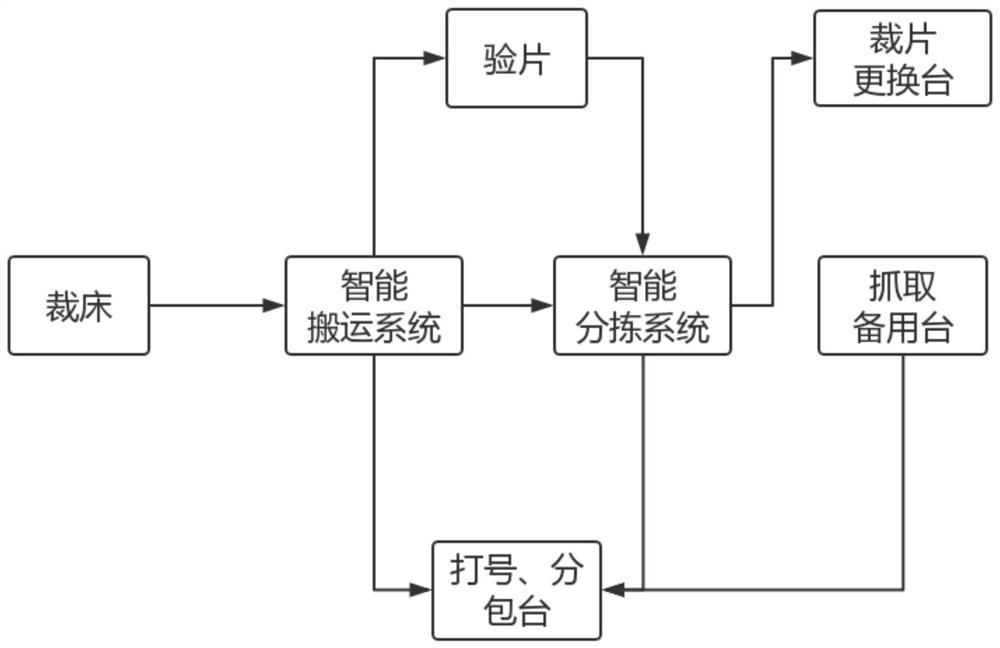

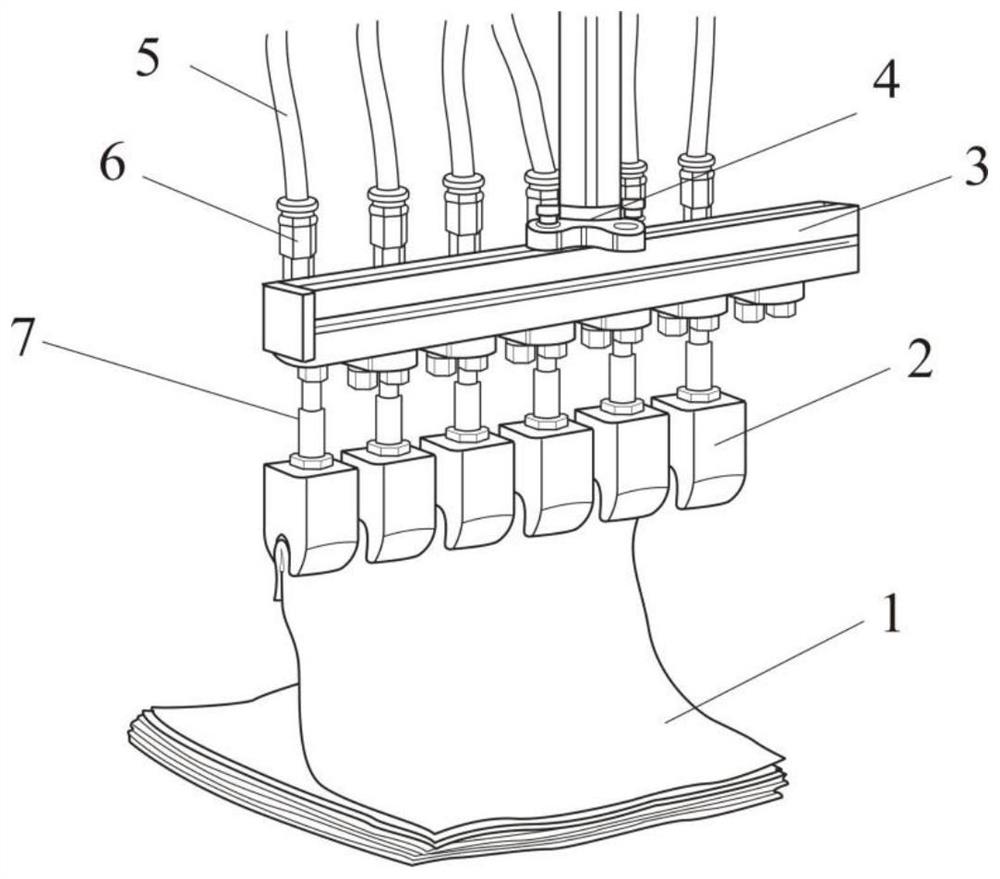

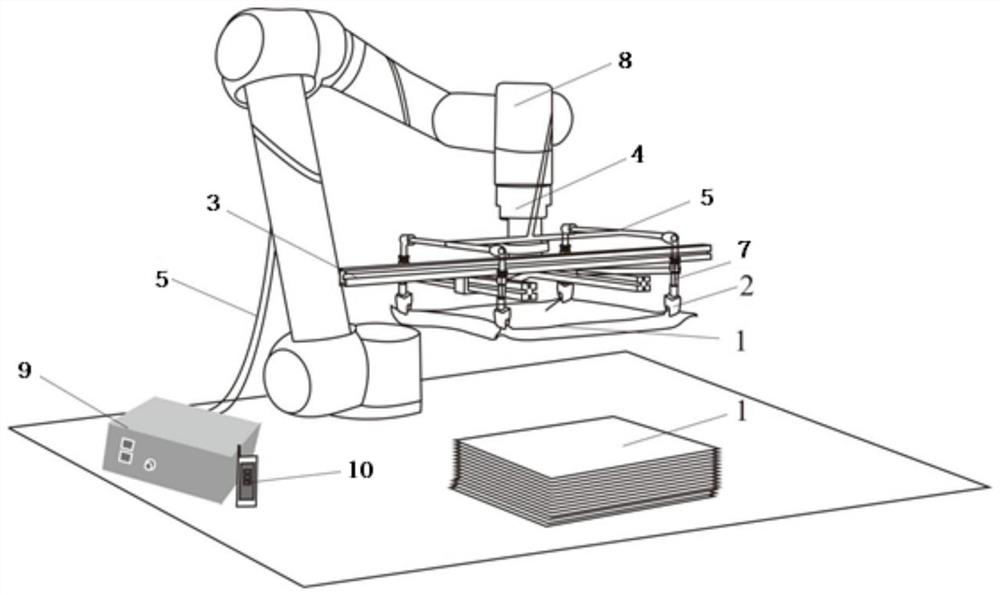

[0029] Automatic separation, inspection, numbering and subcontracting system for textile pieces. The system is centered on the intelligent grasping system, and is electrically connected with a cutting bed, a piece inspection table, a numbering, subcontracting table, a piece changing table and Grab the standby table; wherein, the intelligent grabbing system includes a robot arm 8 and a driver 9 arranged on the platform, the robot arm 8 is connected with at least one profile 3 through the robot arm connector 4, and the driver 9 is connected with the air pipe 5 and along the After the mechanical arm 8 is wound above the profile 3, it is divided into at least 4 branch pipes, each branch pipe is connected with a trachea connector 6, and the other end of the trachea connector 6 is connected with the grab head 2 through the grab head connector 7; Garment pieces 1 are stacked on the platform.

[0030] In the figure, 1 is the clothing piece to be grabbed; 2 is the grabbing head of the ...

Embodiment 2

[0047] Automatic separation, inspection, numbering and subcontracting system for textile pieces. The system is centered on the intelligent grasping system, and is electrically connected with a cutting bed, a piece inspection table, a numbering, subcontracting table, a piece changing table and Grab the standby table; wherein, the intelligent grabbing system includes a robot arm 8 and a driver 9 arranged on the platform, the robot arm 8 is connected with at least one profile 3 through the robot arm connector 4, and the driver 9 is connected with the air pipe 5 and along the After the mechanical arm 8 is wound above the profile 3, it is divided into at least 4 branch pipes, each branch pipe is connected with a trachea connector 6, and the other end of the trachea connector 6 is connected with the grab head 2 through the grab head connector 7; Garment pieces 1 are stacked on the platform.

[0048] In the figure, 1 is the clothing piece to be grabbed; 2 is the grabbing head of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com