Cigarette bar brand sorting, verifying and tracing system and method

A traceability system and cigarette stick technology, applied in other database retrieval, logistics, network data retrieval and other directions, can solve the problems of inability to solve the problem of accountability management, prone to omissions, low customer satisfaction, etc., to improve logistics Efficiency and service quality, improve customer satisfaction, improve the effect of customer experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

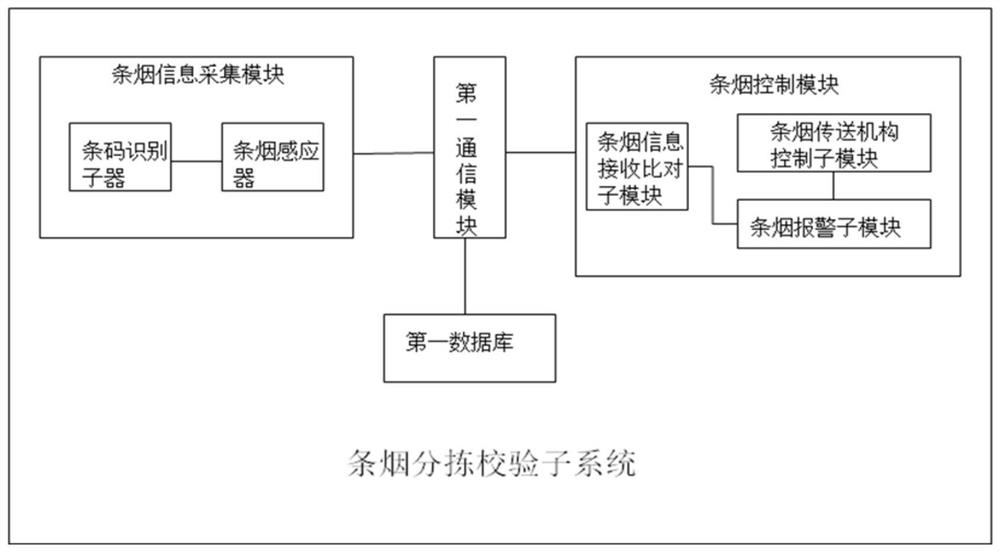

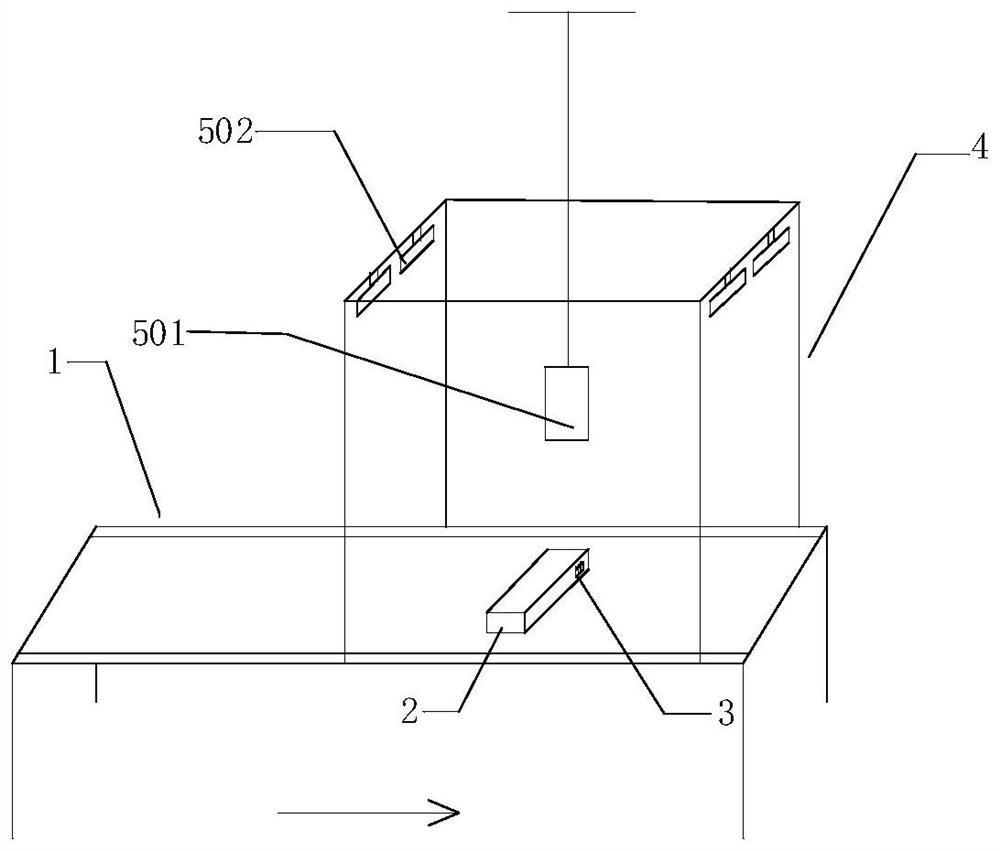

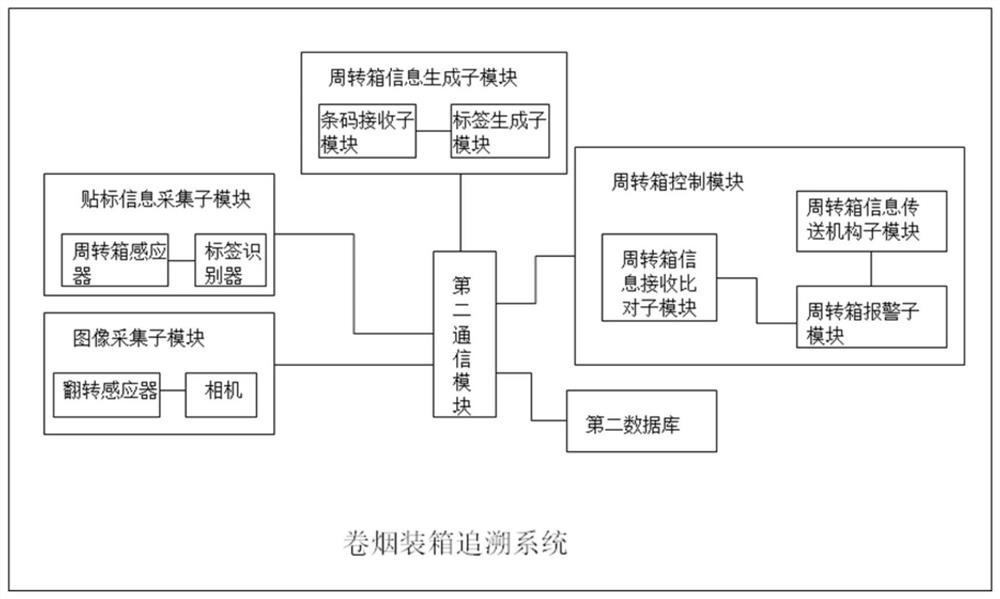

[0031] The system of the present invention includes three major systems: the cigarette sorting and verification subsystem, the turnover box verification subsystem and the weekly packing data traceability management subsystem, wherein the cigarette sorting and verification subsystem is used in the cigarette distribution link. The brand and quantity of the cigarettes are compared and verified with the order data. The turnover box verification subsystem is to verify the cigarettes after they are packed in the cartons and take pictures to store the certificates. The turnover box data traceability management system is for the terminal Users and managers query and analyze the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com