Pretreatment method of molasses used for cement grinding aid

A technology of cement grinding aid and molasses, which is applied in the field of pretreatment of molasses for cement grinding aid, and can solve the problems of high viscosity, many impurities, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Pretreatment of molasses:

[0031] Include the following steps:

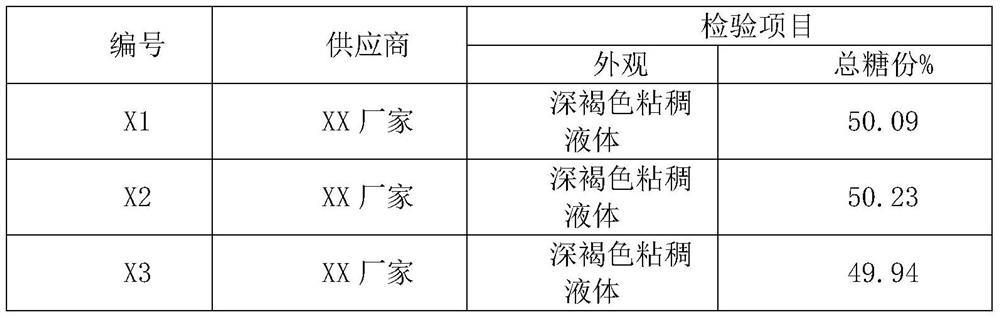

[0032] (1) The DNS method is used to detect the total sugar content of the molasses purchased from the sugar factory, and the calculated total sugar content is 50.09%.

[0033] (2) According to the requirements of viscosity and sugar content in the cement grinding aid formula, the calculated water:molasses=1:1.5 meets the production requirements.

[0034] (3) Add water and molasses into the crystal melting machine according to the ratio of 1:1.5 to stir and dilute to obtain diluted molasses; the stirring speed is 130 rpm, the time is 15 minutes, and the temperature is maintained at 5°C during the period.

[0035] (4) Keep the temperature at 5° C., and let the diluted molasses stand for 20 minutes.

[0036] (5) Keeping the temperature at 5° C., filtering the diluted molasses through a filter tank to obtain finished molasses.

Embodiment 2

[0038] Pretreatment of molasses:

[0039] Include the following steps:

[0040] (1) The DNS method is used to detect the total sugar content of the molasses purchased from the sugar factory, and the calculated total sugar content is 50.23%.

[0041] (2) According to the requirement of viscosity in the formula of cement grinding aid, it is calculated that water:molasses=50:1 meets the production requirements.

[0042] (3) Add water and molasses into the crystal melting machine according to the ratio of 50:1 to stir and dilute to obtain diluted molasses; the stirring speed is 150 rpm, the time is 5min, and the temperature is maintained at 40°C during the period.

[0043] (4) Keep the temperature at 40° C., and let the diluted molasses stand for 10 minutes.

[0044] (5) Keeping the temperature at 40° C., filtering the diluted molasses through a filter tank to obtain finished molasses.

Embodiment 3

[0046] Pretreatment of molasses:

[0047] Include the following steps:

[0048] (1) The DNS method is used to detect the total sugar content of the molasses purchased from the sugar factory, and the calculated total sugar content is 49.94%.

[0049] (2) According to the requirement of viscosity in the formula of cement grinding aid, it is calculated that water:molasses=25:1 meets the production requirements.

[0050] (3) Add water and molasses into the crystal melting machine at a ratio of 25:1 to stir and dilute to obtain diluted molasses; the stirring speed is 140 rpm, the time is 10 minutes, and the temperature is maintained at 20°C during this period.

[0051] (4) Keep the temperature at 20° C., and let the diluted molasses stand for 15 minutes.

[0052] (5) Keeping the temperature at 20° C., filtering the diluted molasses through a filter tank to obtain finished molasses.

[0053] 2. Detection example:

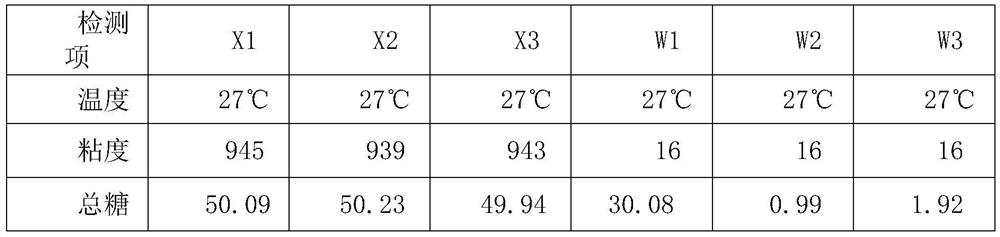

[0054] The initial molasses product and finished molasses used i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com