Method for assisting in hydrolyzing glucosinolate in mustard seeds into isothiocyanate by combining ultrahigh static pressure with conversion liquid

A technology of glucosinolate and isothiocyanate is applied in the field of hydrolyzed mustard seed where glucosinolate is isothiocyanate, which can solve the problems of low production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

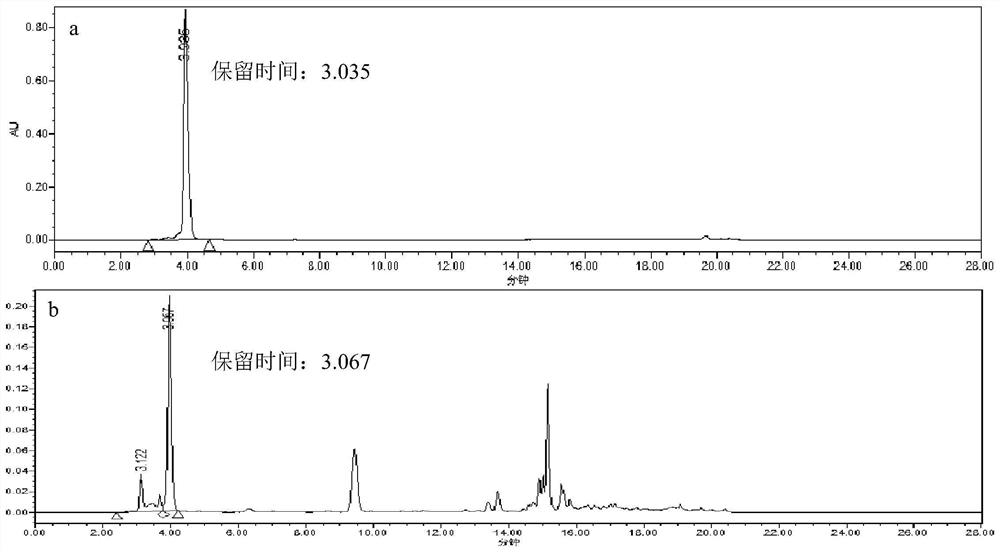

[0031] The conversion of glucosinolates in white mustard into isothiocyanates includes the following steps:

[0032] (1) Weigh the sample 50g;

[0033] (2) Mix it with the transformation solution at a ratio of 1:5 (g / ml) (pH=7, containing 18mM ascorbic acid, 15mM EDTA, and the temperature is 50°C);

[0034] (3) Refining in the colloid mill to reach an average particle size of 62 μm;

[0035] (4) Put it into PET vacuum packaging bag;

[0036] (5) Perform ultra-high static pressure treatment, keep it under 600MPa pressure for 20 minutes, and then release the pressure to take it out. Complete hydrolysis within 30 minutes, glucosinolates converted to isothiocyanates.

Embodiment 2

[0047] The glucosinolate in the white mustard is converted into isothiocyanate and comprises the following steps:

[0048] (1) Weigh the sample 50g;

[0049] (2) Mix it with the transformation solution at a ratio of 1:1 (g / ml) (pH=9, containing 4.5mM ascorbic acid, 30 mM EDTA, and the temperature is 40°C);

[0050] (3) Refining in the colloid mill to reach an average particle size of 315 μm;

[0051] (4) Put it into PET vacuum packaging bag;

[0052] (5) Perform ultra-high static pressure treatment, keep it under 450MPa pressure for 15 minutes, then release the pressure and take it out; within 30 minutes, it will be completely hydrolyzed, and glucosinolates will be converted into isothiocyanates;

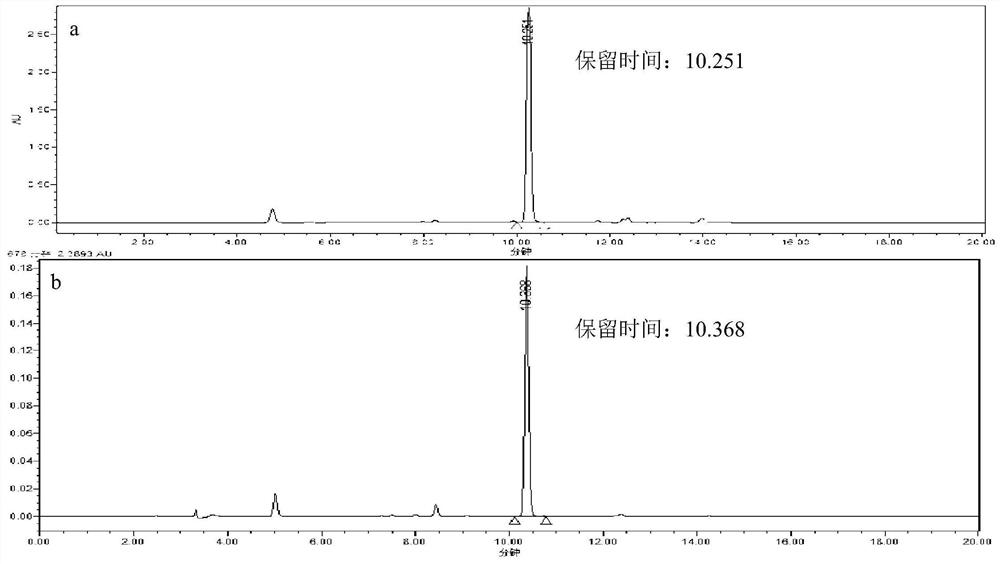

[0053] (6) Detection of isothiocyanates and glucosinolates: the content of total isothiocyanates in samples treated with ultra-high static pressure reached 19.6 mg / g mustard.

[0054] (7) After fully stirring the treated mustard seed and corn oil at a ratio of 1:5 for 15 minutes,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap