Assembled soil nail wall structure and construction method

A construction method and technology of soil nailing wall, which are applied in basic structure engineering, excavation, construction, etc., can solve the problems of difficult to apply to small-scale foundation pit support, large volume and weight, inconvenience, etc., and achieve quality reduction, construction safety and convenience, The effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

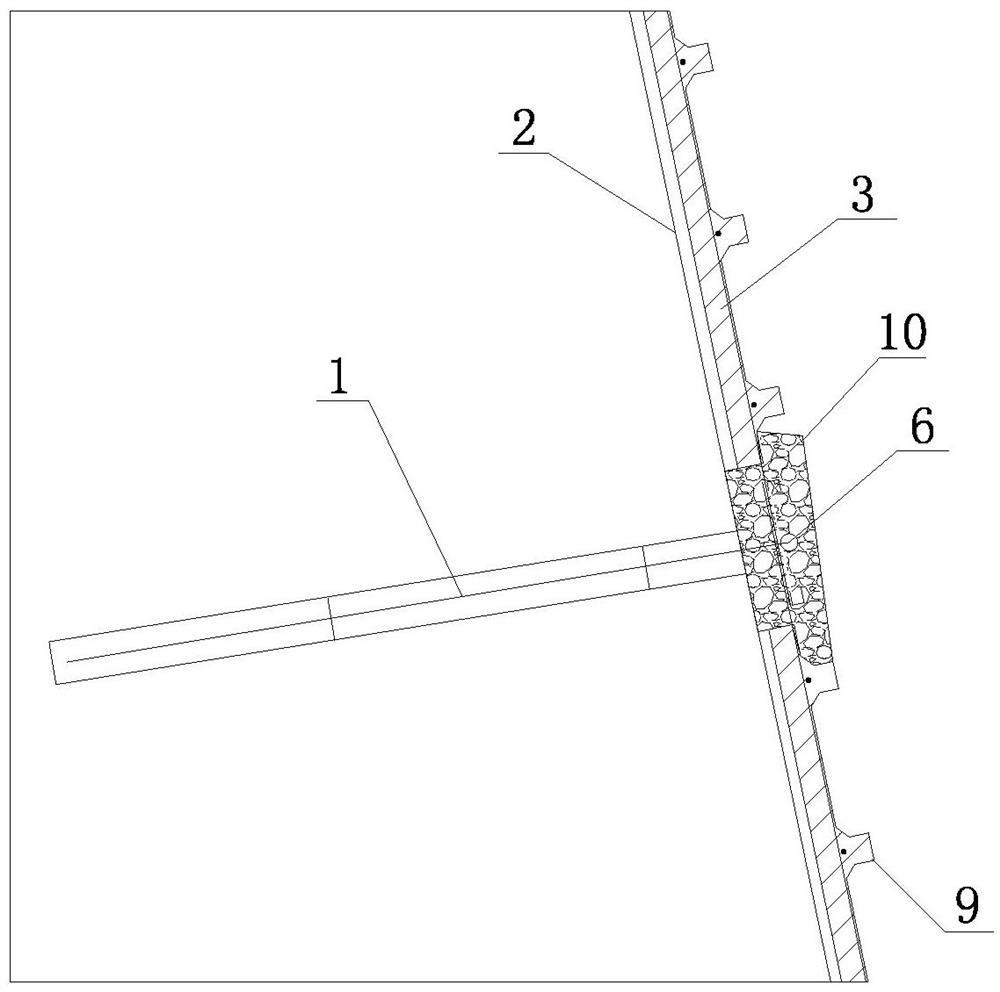

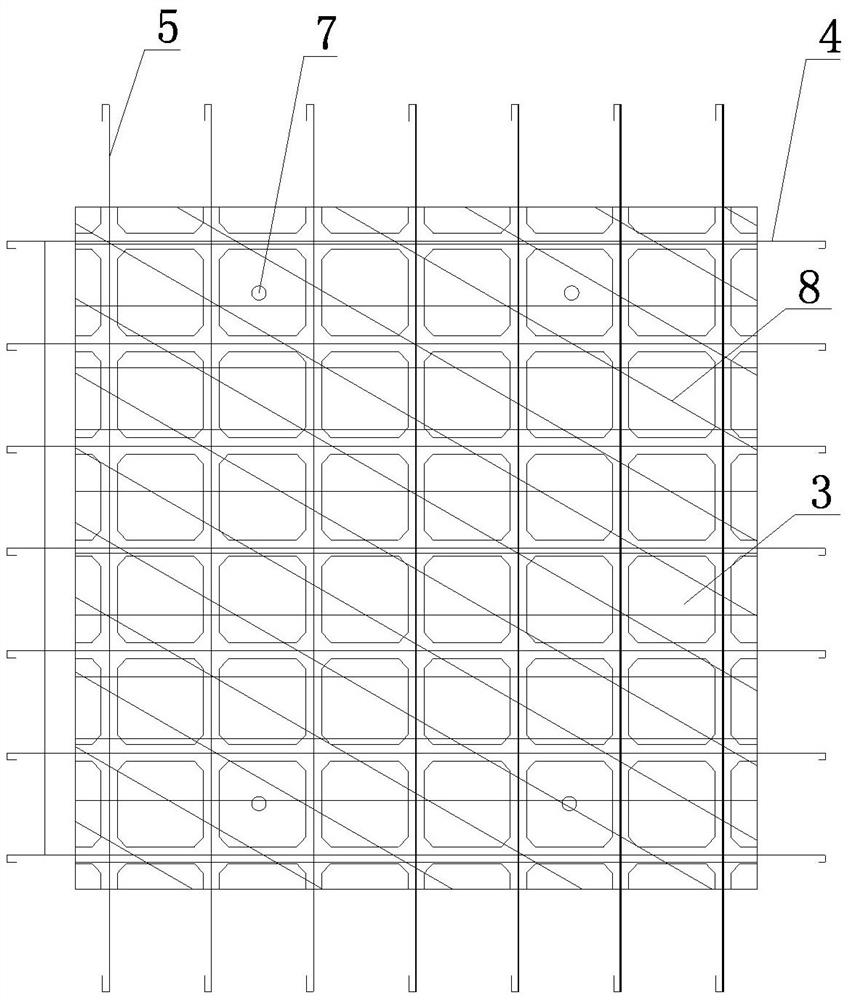

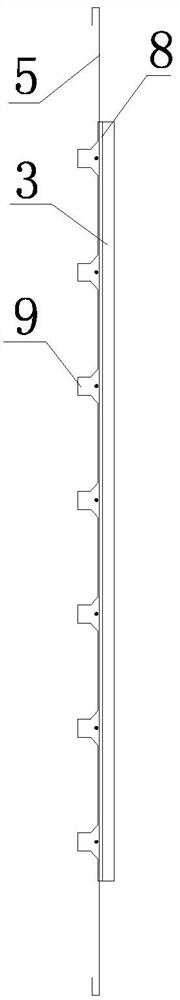

[0030] as attached Figure 1-6 As shown, the assembled soil nail wall structure of the present invention includes soil nails 1 fixed and evenly spaced along the horizontal direction in the soil nail holes on the slope surface 2 and prefabricated lattice panels arranged on the slope surface 2; The soil nails 1 and the prefabricated lattice panels are arranged in a row; the exposed ends of the soil nails 1 are bent; the bent ends of each row of soil nails 1 are connected to the horizontal ribs 6; each row of soil nails 1 is reinforced horizontally The ribs 6 are fixed to the adjacent upper and lower rows of prefabricated lattice panels; the prefabricated lattice panels include lattice panels 3 poured with foamed fine stone concrete, and transverse steel bars 4 uniformly arranged in the lattice panels 3 And the longitudinal steel bar 5 that is evenly arranged on the horizontal steel bar 4 at intervals, in order to increase the strength, a fine diamond-shaped mesh 8 is set in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com