Heat recycling system for reaction water in chemical production

A technology for heat recovery and chemical production, applied in biological water/sewage treatment, indirect heat exchangers, heat exchange equipment, etc., can solve problems affecting heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

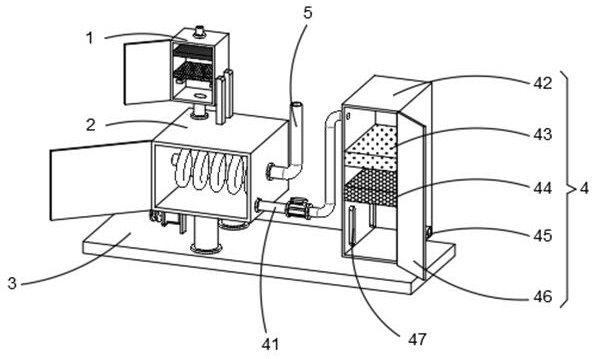

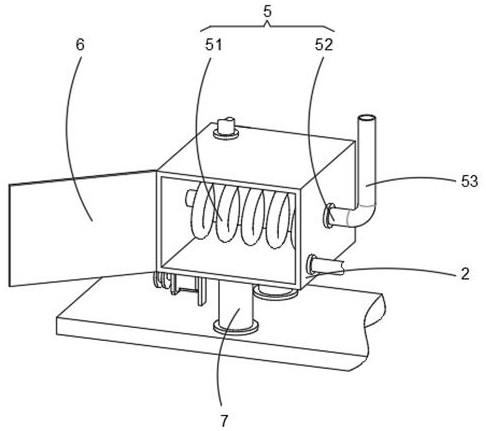

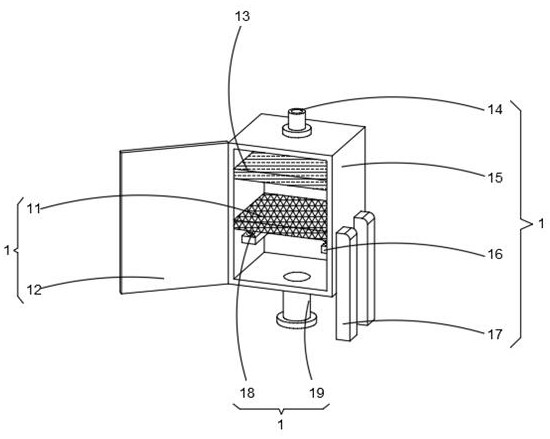

[0027] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the chemical production reaction water heat recovery and utilization system provided by the present invention; figure 2 for figure 1 The schematic diagram of the partial structure of the chemical production reaction water heat recovery and utilization system shown; image 3 for figure 1 The structural schematic diagram of the reaction water inlet mechanism shown; Figure 4 for figure 1 The schematic diagram of the axonometric structure of the chemical production reaction water heat recovery and utilization system shown; Figure 5 for Figure 4 Partial enlarged view of A in the center. The chemical production reaction water heat recovery system includes: a base 3; a box body 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com