Pipe ring flatness measuring method based on total station

A measurement method and technology of total station, applied in the directions of measurement device, measurement instrument, measurement inclination, etc., can solve the problems of affecting calculation accuracy, poor measurement flexibility, poor measurement accuracy, etc., and achieve high measurement accuracy and low measurement cost. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in combination with specific embodiments.

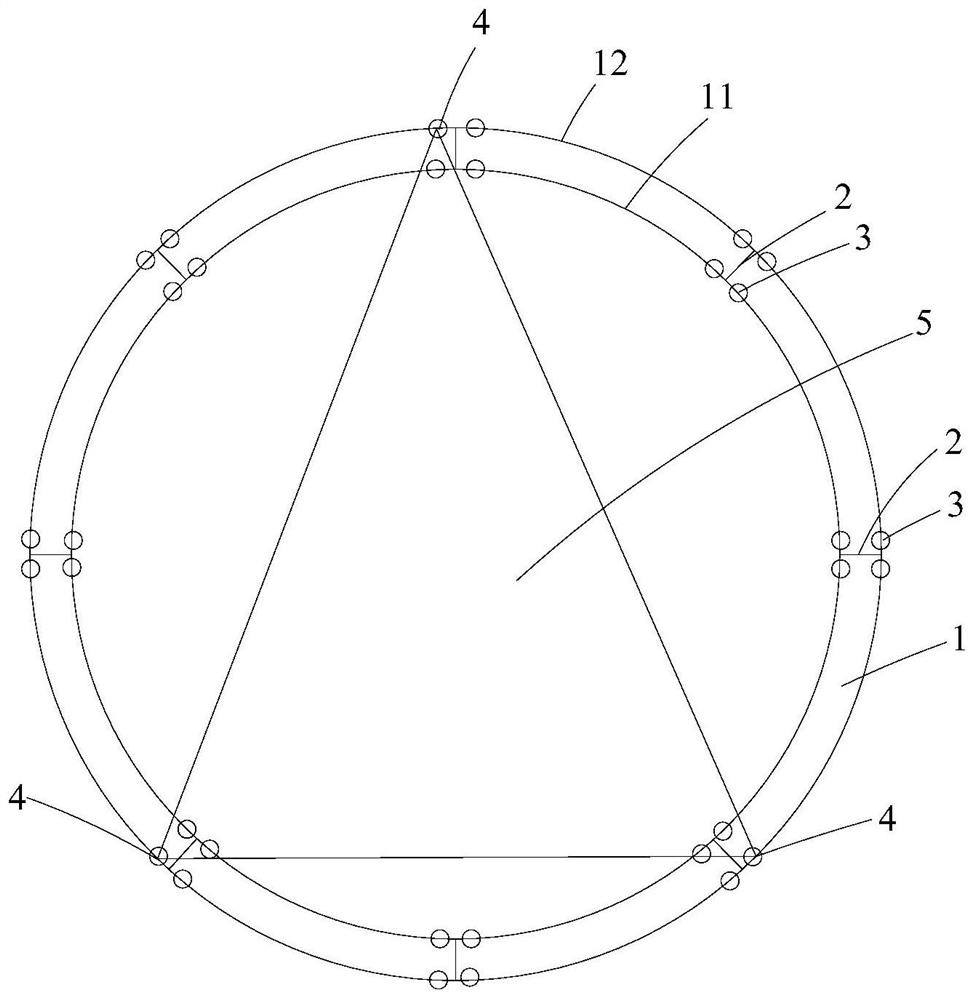

[0025] The invention relates to the improvement of the measurement method for the flatness of pipe rings of multiple segments, so as to solve the problems of poor flexibility, poor precision and high cost in the current measurement method. An improved measurement method for pipe ring flatness, by pre-selecting two mandatory center points and using a total station to detect the coordinates of multiple measurement points on the end face of the pipe ring at these two points, and then using the plane formula and the point-to-surface distance The formula can calculate the flatness deviation of each measurement point, the steps are simple, the operation is convenient, and the flatness of the pipe ring end face can be calculated flexibly and quickly, the measurement accuracy is high and the measurement cost is low.

[0026] Specifically, a method for mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com