Harmonic oscillator and electrode fixed connection method suitable for high-vacuum environment

A resonator, high vacuum technology, used in instruments, gyroscopic effects for velocity measurement, surveying and navigation, etc., can solve the problem of no structural connection and fixation patent and other problems, avoid oxidation and a large amount of inhalation, is conducive to vacuum performance, Effects of low outgassing vacuum performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below with reference to the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

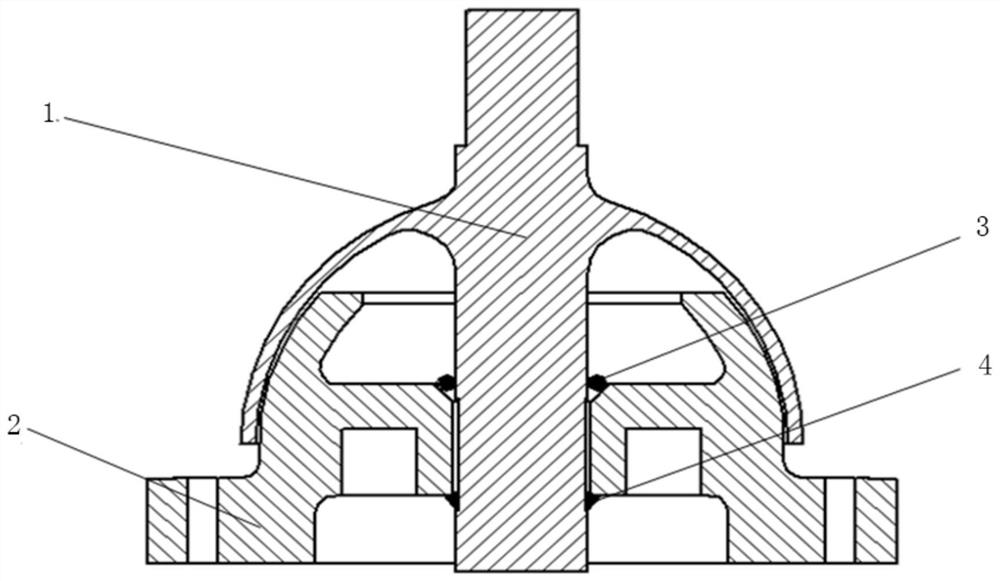

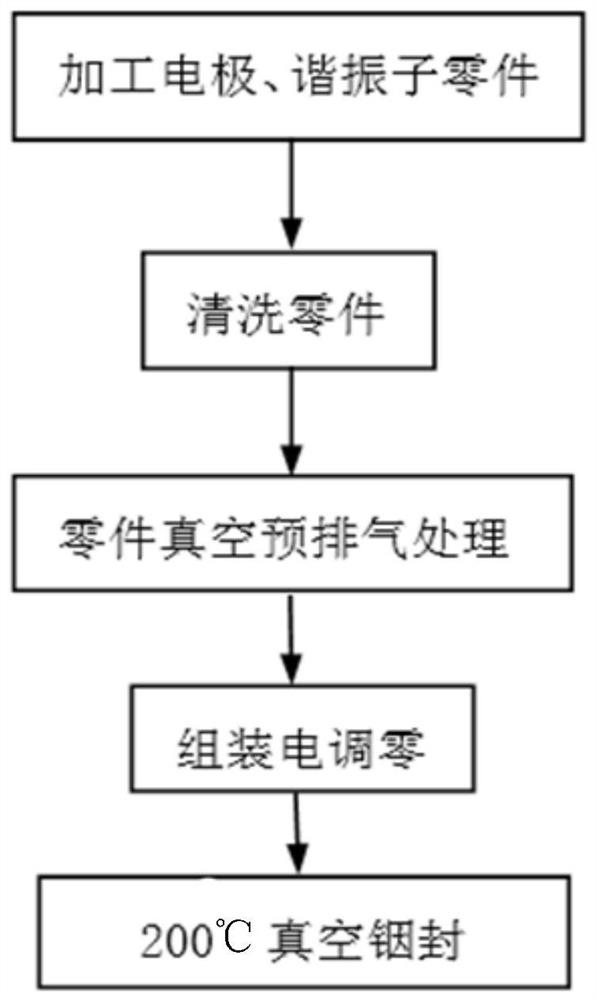

[0023] A fixed connection method of resonator and electrode suitable for high vacuum environment, see figure 1 and 2 , its invention point is: comprising the following steps:

[0024] Step 1. Process the resonator part 1 and the electrode part 2: the diameter of the center hole of the electrode part is larger than the diameter of the center rod of the resonator part, and there is a matching gap between the two. The preferred matching gap size is: 0.1±0.02mm , and make a chamfered surface on the center hole of the electrode part;

[0025] Step 2: Clean the resonator parts and the electrode parts to remove the grease on the surface of the parts; the cleaning is preferably realized by multiple steps of rough washing, degreasing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com