Fuel cell proton exchange membrane with micro texture and processing method of fuel cell proton exchange membrane

A proton exchange membrane and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of unfavorable large-scale commercial production, long time-consuming, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

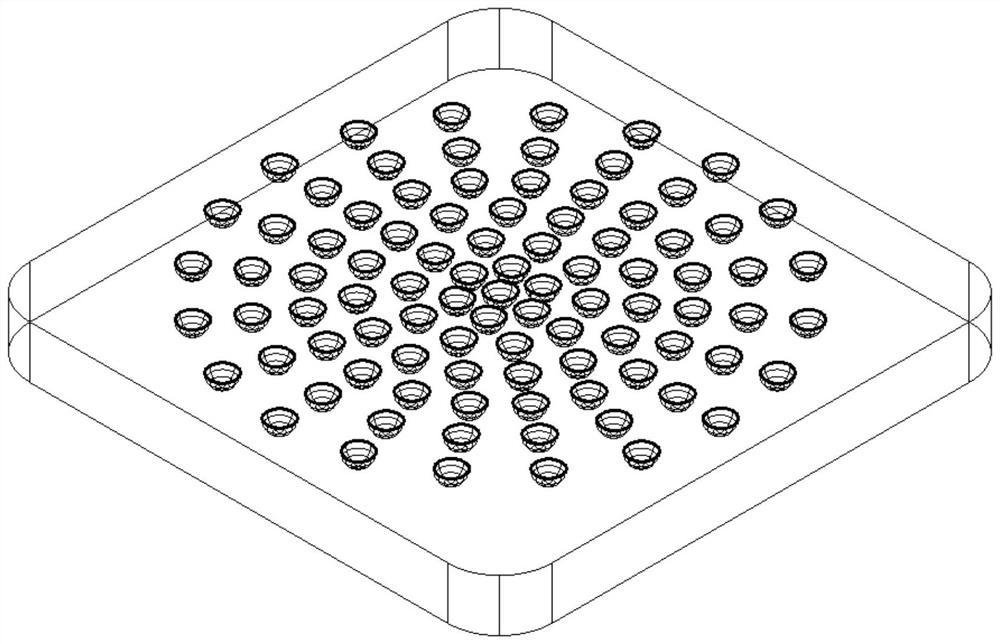

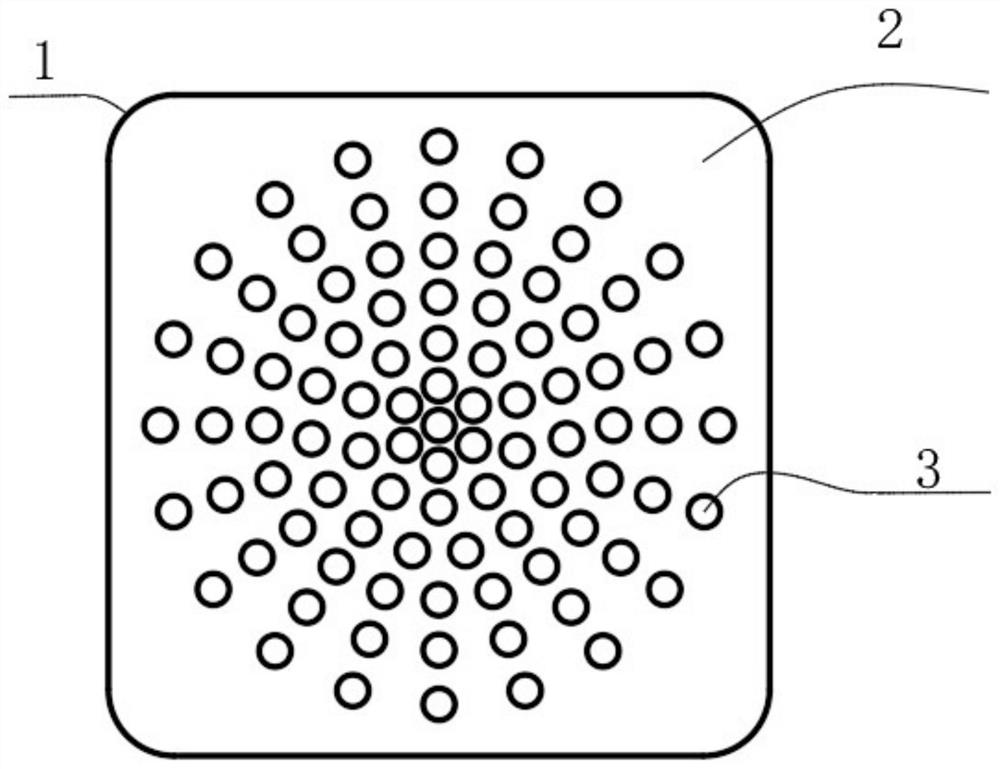

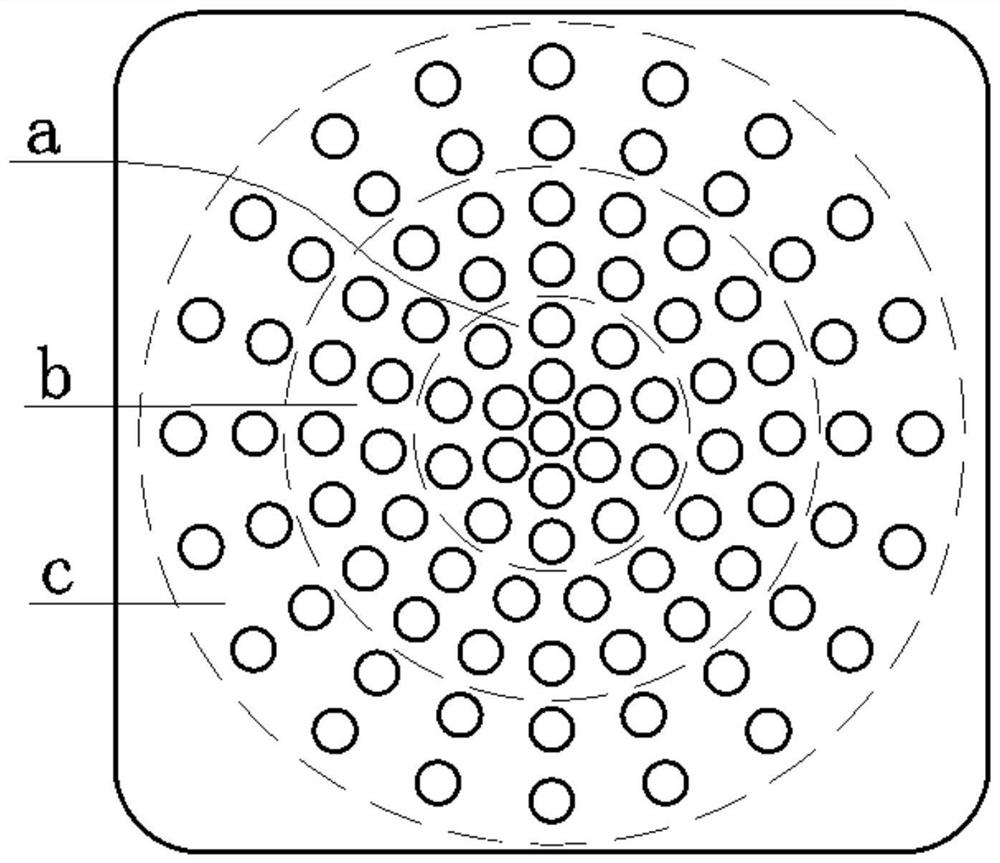

[0045] Such as figure 1 , 2 As shown in , 3, the fuel cell proton exchange membrane with microtexture according to the present invention, the proton exchange membrane 1 is a perfluorosulfonic acid type proton exchange membrane with a length of 50 mm, a width of 50 mm and a thickness of 50 μm. The cathode surface 2 of the proton exchange membrane is distributed with a number of petal-shaped concave-convex composite textures 3 according to the gradient of inner density and outer sparseness. The concave-convex composite texture 3 includes pits 4 and protrusions 5. A ring protrusion 5, and a number of semi-ellipsoidal micro-pits 6 are evenly distributed on the inner surface of the pit 4. The pit 4 can be a hemispherical pit, and the pit 4 can also be a circular hole, the bottom of which is a hemispherical surface tangent to the cylindrical surface of the circular hole. The protrusion 5 may be a hemispherical protrusion, or the protrusion 5 may be a cylinder, and the top of the c...

Embodiment 2

[0049] Such as Figure 4 , 5 As shown in 6 and 6, the proton exchange membrane of the fuel cell with microtexture according to the present invention, the proton exchange membrane 1 is a perfluorosulfonic acid type proton exchange membrane with a length of 50 mm, a width of 50 mm and a thickness of 50 μm. The cathode surface 2 of the proton exchange membrane is distributed with a number of petal-shaped concave-convex composite textures 3 according to the gradient of inner density and outer sparseness. The concave-convex composite texture 3 includes pits 4 and protrusions 5. A ring protrusion 5, and a number of semi-ellipsoidal micro-pits 6 are evenly distributed on the inner surface of the pit 4. The pit 4 can be a hemispherical pit, and the pit 4 can also be a circular hole, the bottom of which is a hemispherical surface tangent to the cylindrical surface of the circular hole. Several concave-convex composite textures 3 are rectangularly distributed on the cathode surface 2;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Long axis length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com