A kind of manufacturing method of flexible microwave filter

A technology of microwave filter and manufacturing method, which is applied in the direction of waveguide devices, instruments, measuring devices, etc., and can solve the problems that the electrical and mechanical properties cannot fully meet the actual needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

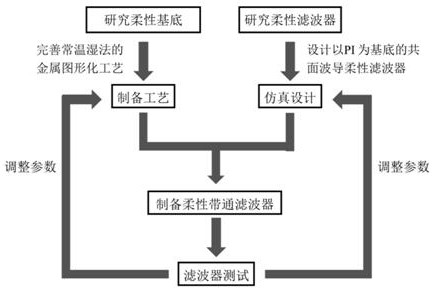

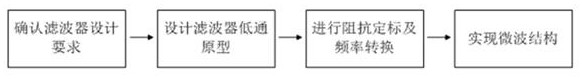

Method used

Image

Examples

Embodiment Construction

[0046] In order to facilitate the understanding of the present invention, the technical solution of the present invention will be specifically introduced below in conjunction with examples.

[0047] The main raw materials adopted in the manufacturing process of the present invention are as shown in Table 1, and the reagents and raw materials used in the experimental process are relatively common experimental reagents.

[0048] Table 1 Main experimental reagents and raw materials

[0049]

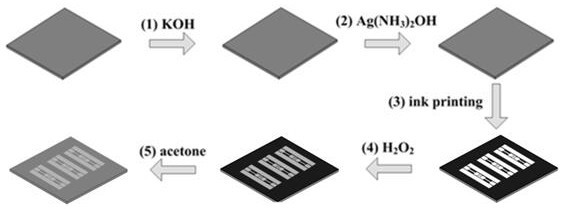

[0050] The whole manufacturing process is carried out under normal temperature and pressure, and its main process steps are:

[0051] a. to clean

[0052] The cleanliness of the polyimide surface directly affects the performance of the final composite film. Therefore, before starting the reaction, the polyimide film was cleaned with a large amount of absolute ethanol and acetone solution.

[0053] b. Hydrolysis reaction

[0054] Prepare 100 ml of KOH solution and set its concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com