Manufacturing method of infrared composite heating device for ice prevention and removal and heating device

A composite heating and manufacturing method technology, applied in the field of vehicles, can solve the problems of limited medium volume, increased vehicle load, limited number of deicing times, etc., and achieves the effect of reducing weight, eliminating suspension installation, and satisfying rail fire protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

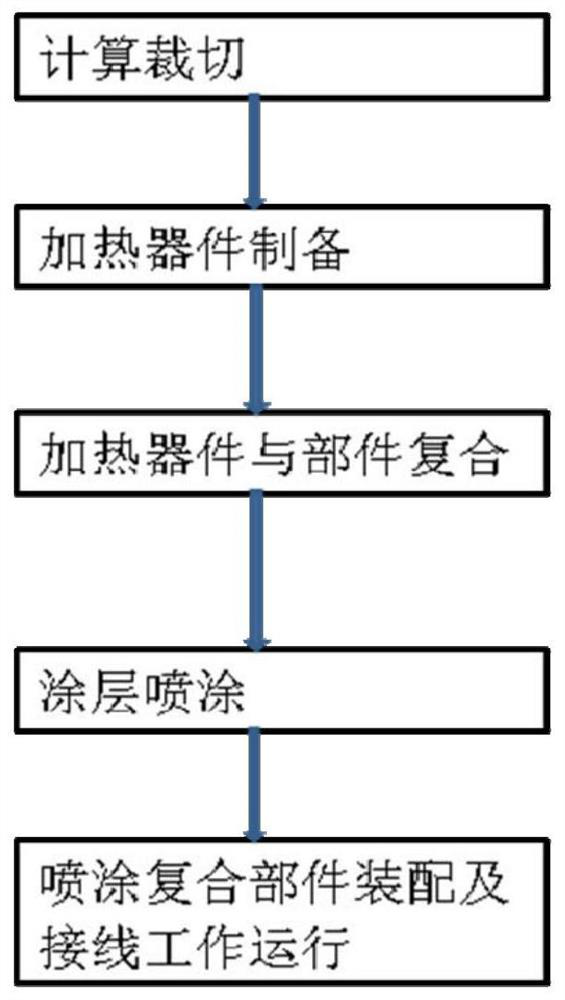

[0048] The specific process of the manufacturing method of the disclosed device is as follows:

[0049] step 1)

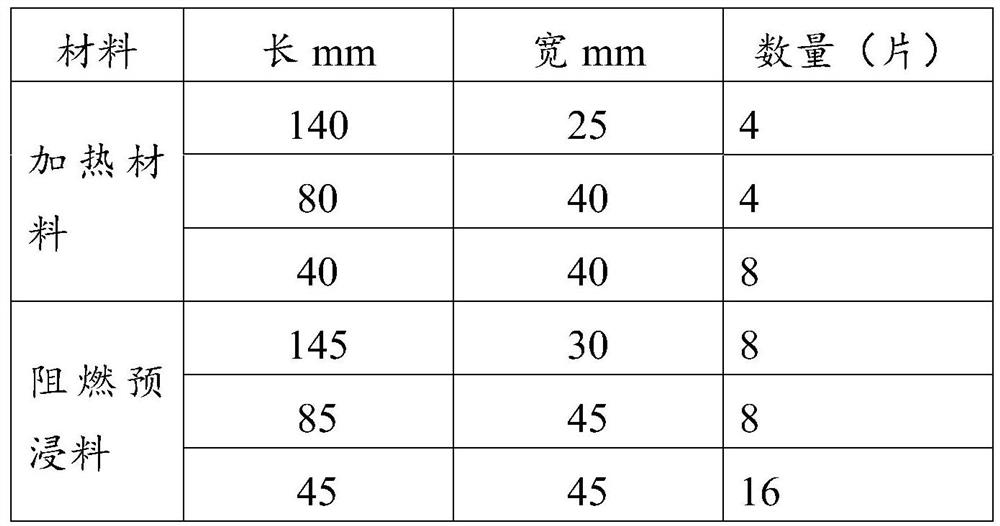

[0050] Cut the material according to the size and quantity in Table 1,

[0051] Table 1

[0052]

[0053] Step 2)

[0054] The copper sheet is sewed or laminated at the two edges perpendicular to the carbon fiber orientation of the heating material, and then covered with prepreg and hot-pressed at 130°C and 0.3MPa for 60 minutes to obtain a heating element.

[0055] step 3)

[0056] Prepreg layup is carried out on the heating area of the component, and the prepared heating components are distributed and pasted on the prepreg layup and connected with wires. It is then covered with prepreg.

[0057] Step 4)

[0058] The laminated parts are vacuum bagged at 130°C for 60 minutes to obtain composite parts with heating function

[0059] Step 5)

[0060] For the composite part obtained in step 4), a hydrophobic layer is sprayed with a hydrophobic material con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com