Patents

Literature

37results about How to "Promote lightweight development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

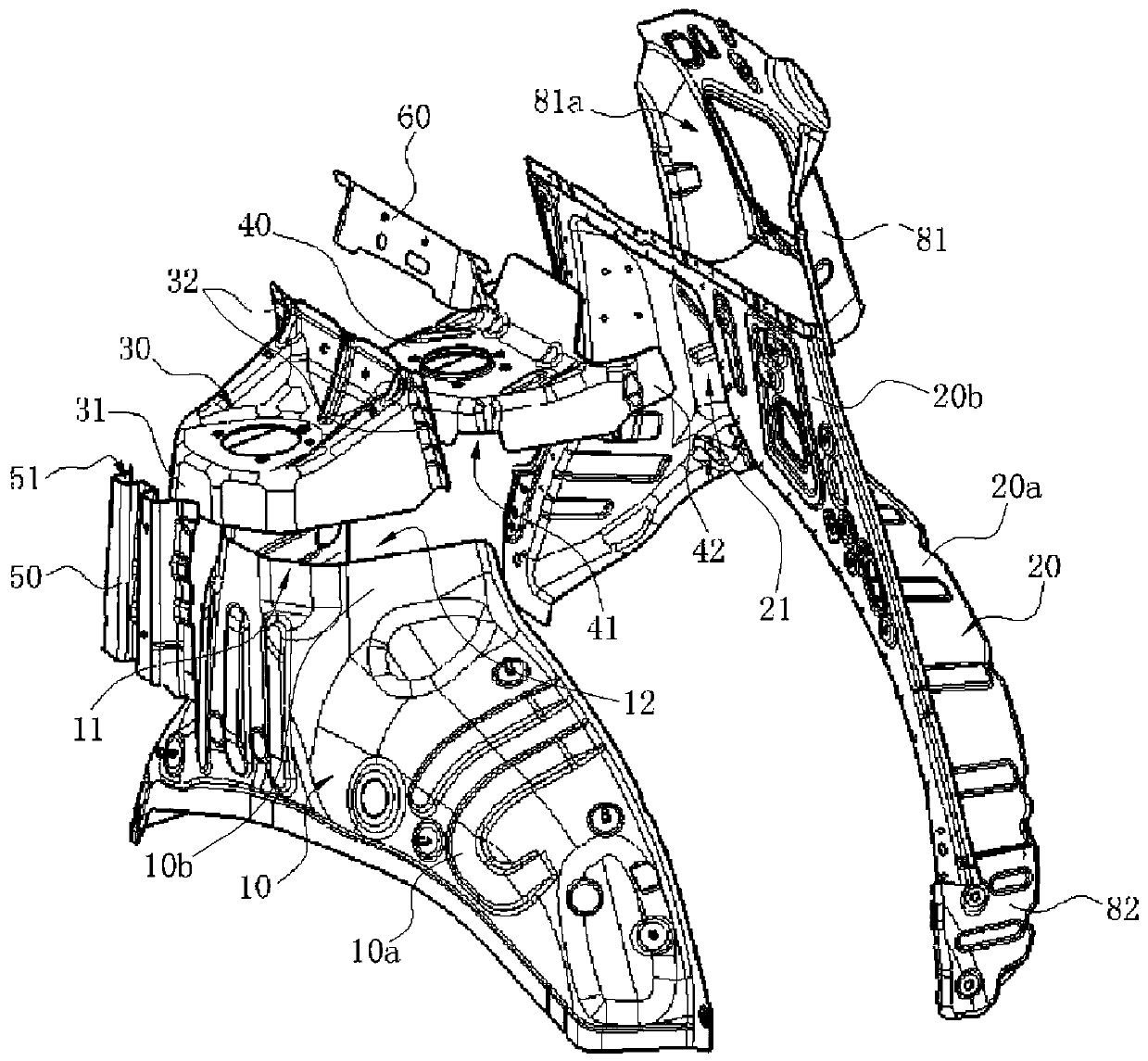

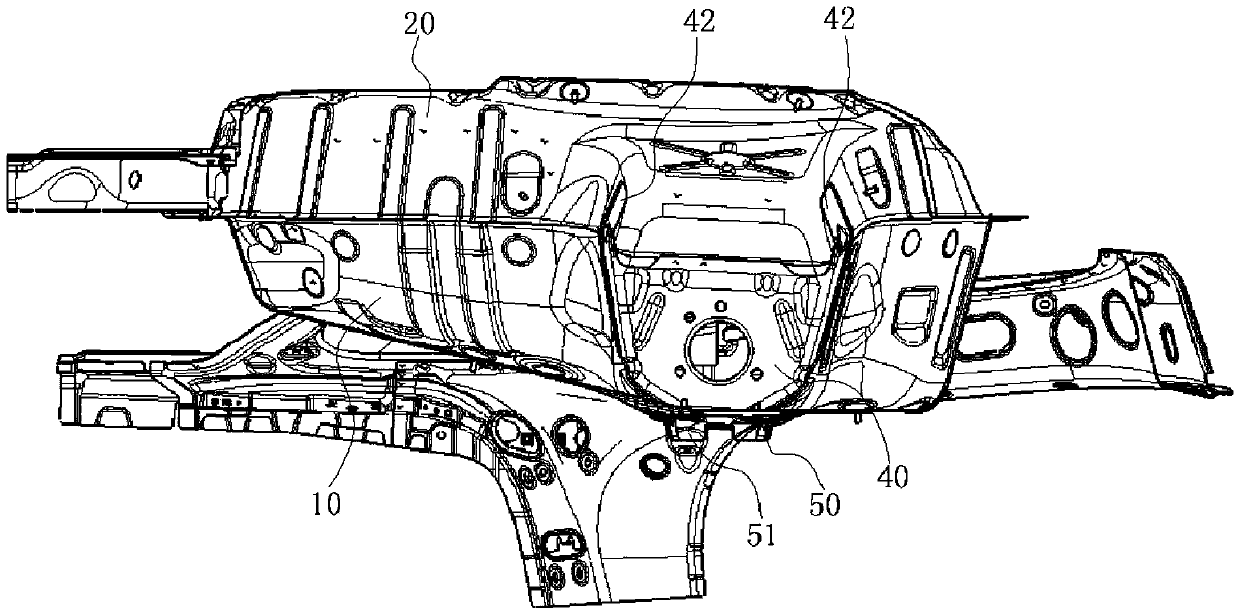

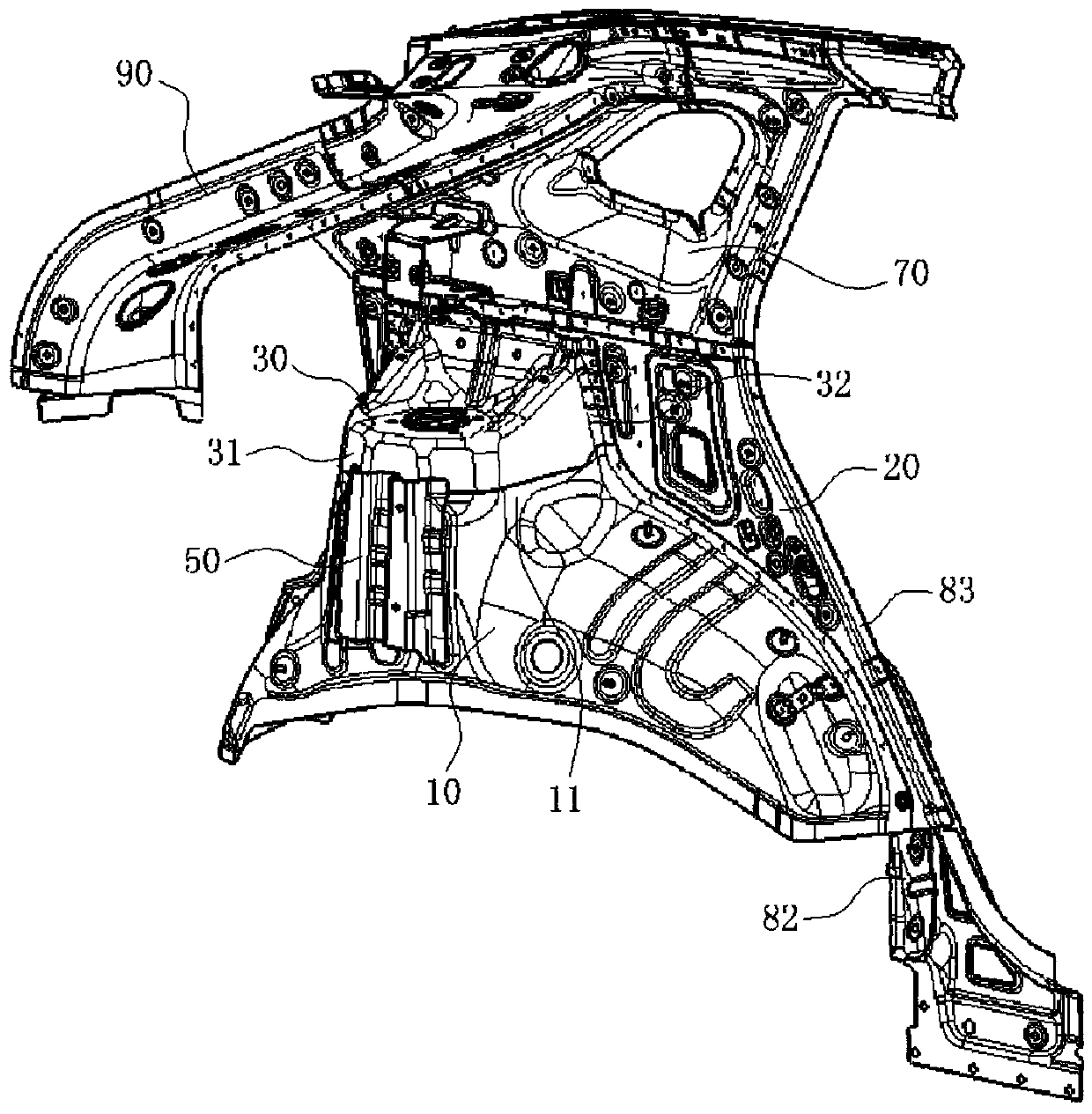

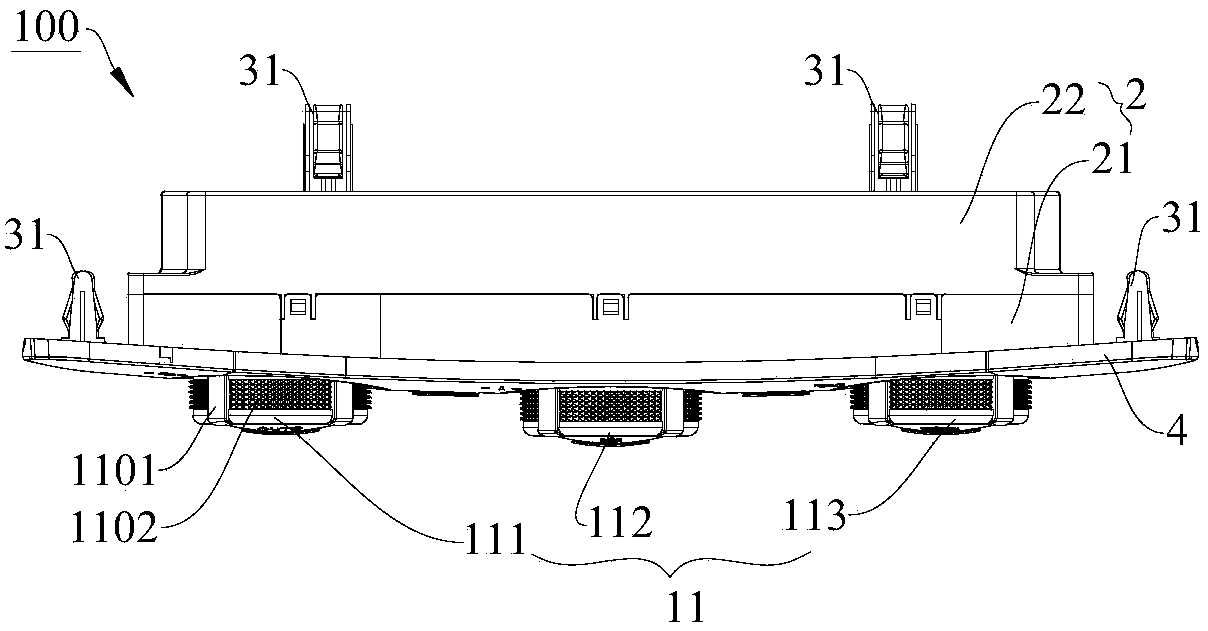

Vehicle body rear structure and automobile

PendingCN111332368AHigh strengthIncrease stiffnessSuperstructure subunitsStructural engineeringSuspension (vehicle)

The invention provides a vehicle body rear structure. The vehicle body rear structure comprises a rear wheel cover outer plate; the rear wheel cover inner plate is arranged opposite to the rear wheelcover outer plate and connected with the rear wheel cover outer plate in a matched mode; the lower edge part of the rear suspension mounting plate is connected with the upper edge part of the rear wheel cover inner plate, and the side edge part of the rear suspension mounting plate is connected with the inner wall of the rear wheel cover outer plate; and the rear suspension reinforcing plate is arranged in the rear suspension mounting plate, the lower edge part of the rear suspension reinforcing plate is connected with the upper edge part of the rear wheel cover inner plate, and the rear suspension reinforcing plate forms a first columnar cavity between the rear wheel cover inner plate and the rear wheel cover outer plate. According to the rear structure of the vehicle body, through reasonable structural design, the problems of poor rigidity, strength and NVH (Noise Vibration and Harshness) performance of back-sliding type vehicles, steel-aluminum hybrid vehicles, vehicles without cross beams on rear floors and other types of vehicles are well solved while structural light weight is considered. The invention further provides a vehicle comprising the vehicle body rear structure.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

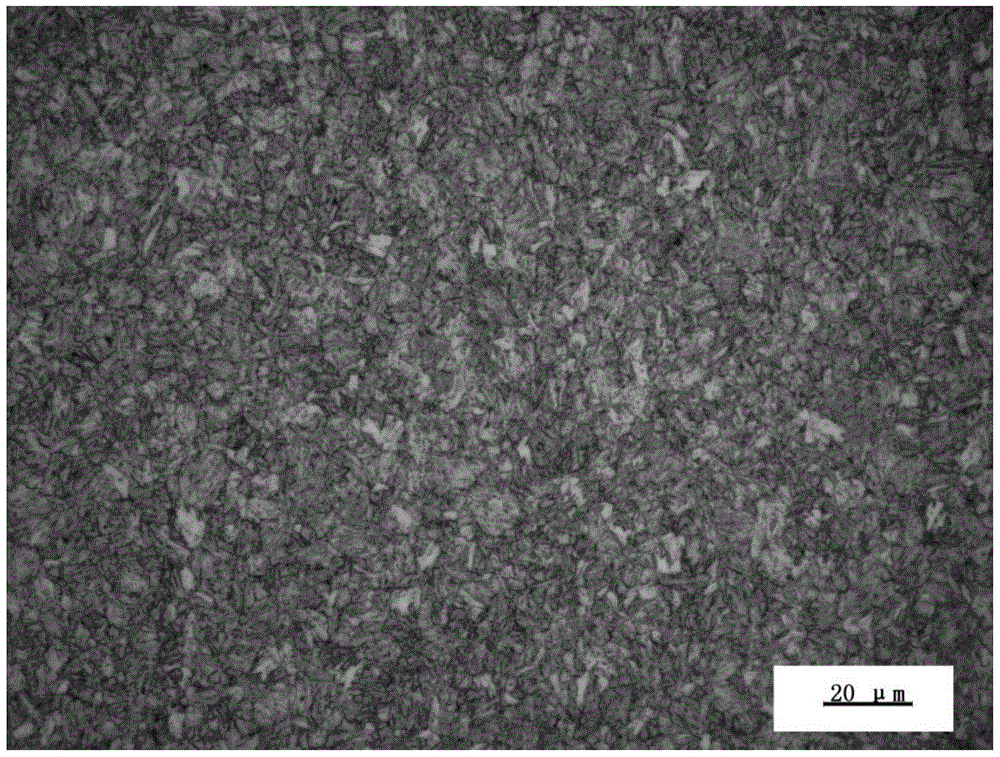

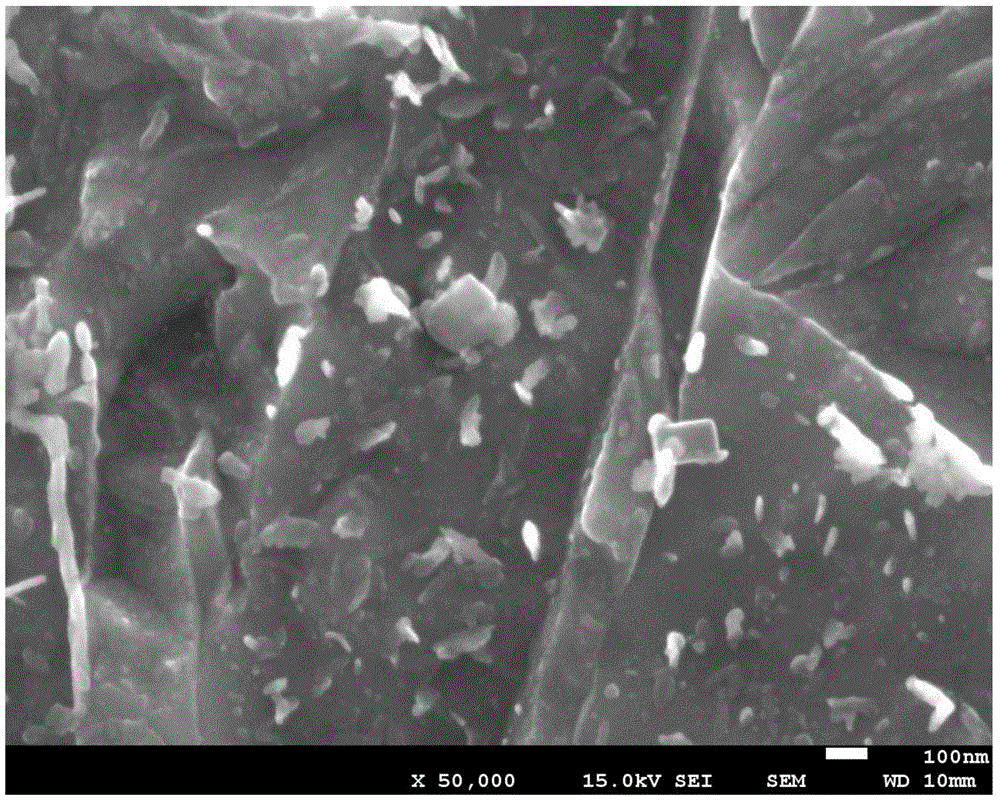

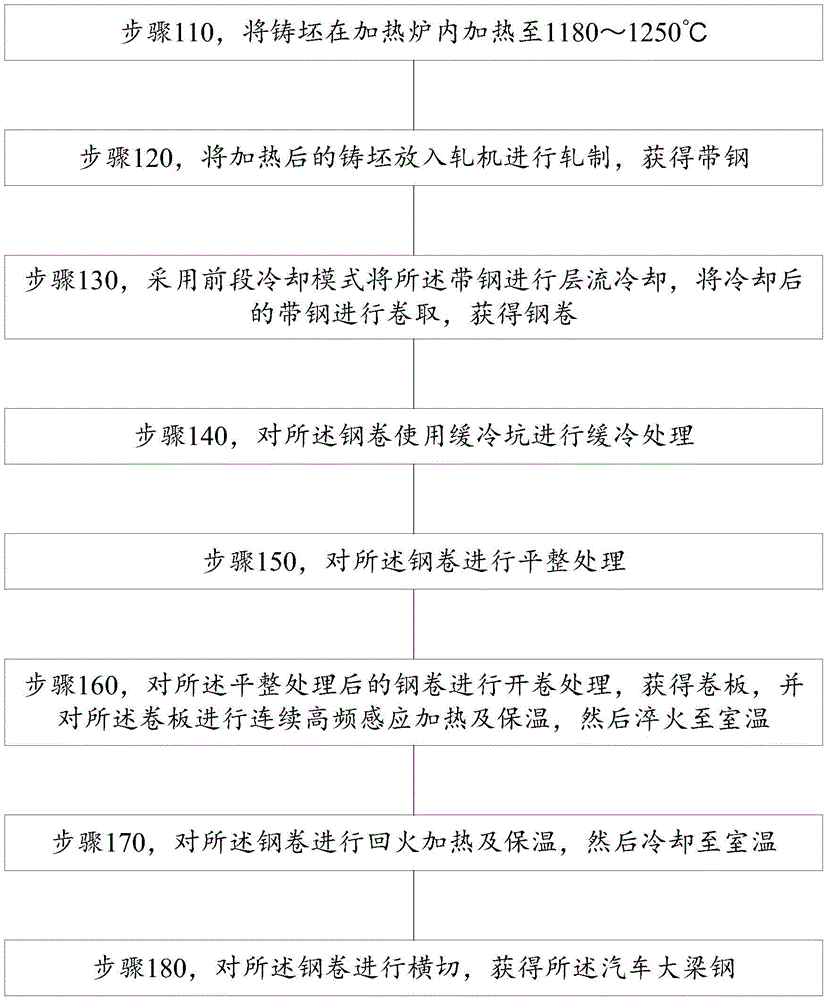

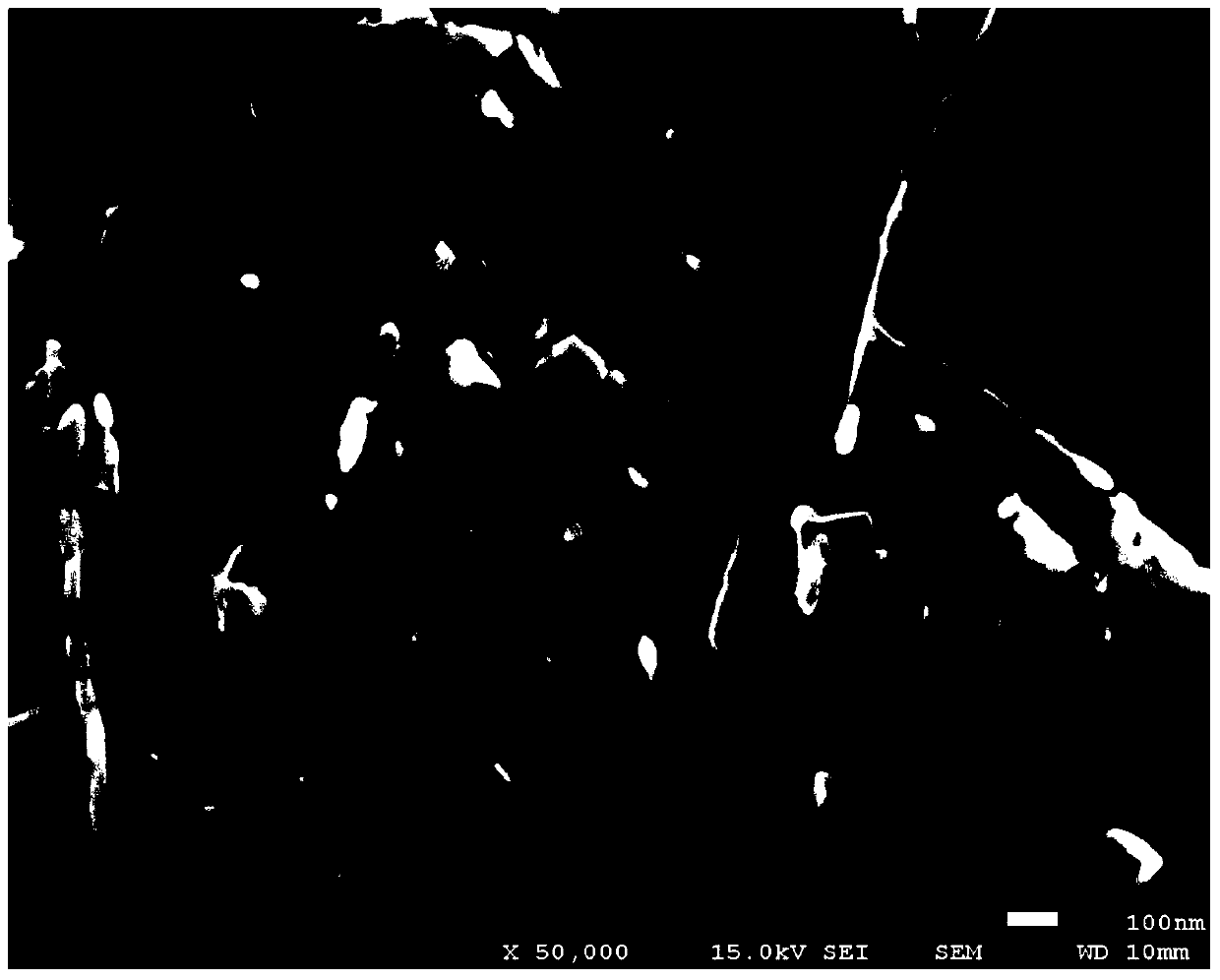

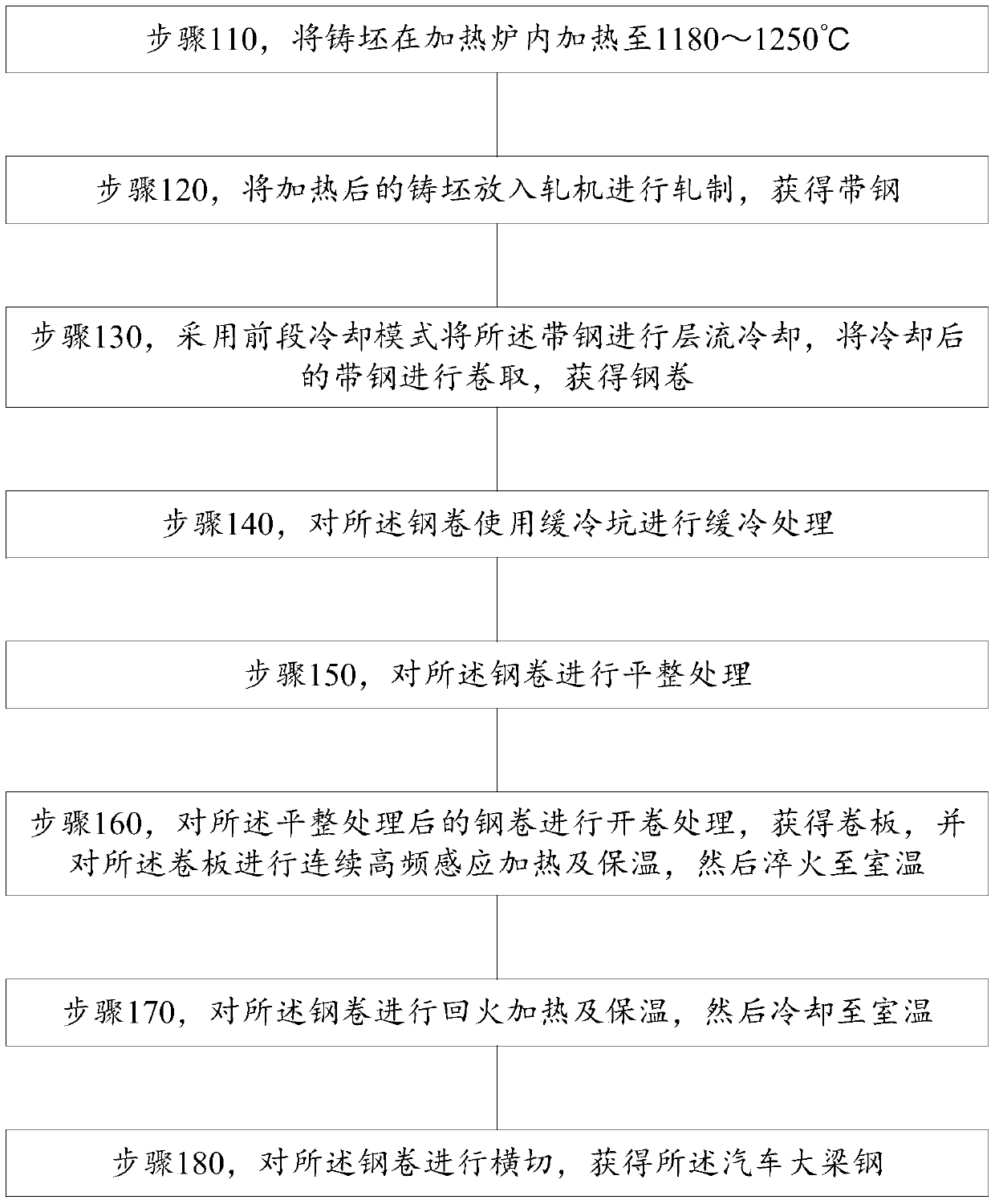

Automobile beam steel with 960 MPa yield strength and production method thereof

The invention discloses automobile beam steel with 960 MPa yield strength and a production method thereof. The automobile beam steel comprises the following chemical components in percent by weight: 0.12-0.14 percent of C, 0.15-0.35 percent of Si, 1.2-1.5 percent of Mn, 0.02-0.04 percent of Nb, 0.3-0.5 percent of Mo, 0.08-0.15 percent of V, 0.01-0.04 percent of Ti, 0.01-0.06 percent of Al, 0.4-0.6 percent of Cr, 0.0015-0.0025 percent of B, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.008 percent of N, and the balance of Fe and inevitable impurities. C and Mn with low content are adopted, the separation strengthening effects of V, Nb and Ti are sufficiently utilized, and besides, a certain amount of Mo, a certain amount of Cr and a certain amount of B are added to control the heat treatment structure state, so that a fine and uniform tempering structure is obtained, the steel has high toughness, high welding performance and high low-temperature impact toughness, the safety performance of a vehicle is improved, the light-weight development of the vehicle is facilitated, and the technical problems that in the prior art, since the low-temperature impact toughness of steel is low, the potential safety hazards of a vehicle are caused, and the lightweight development of the vehicle is limited since the strength of the steel is low.

Owner:SHOUGANG CORPORATION +1

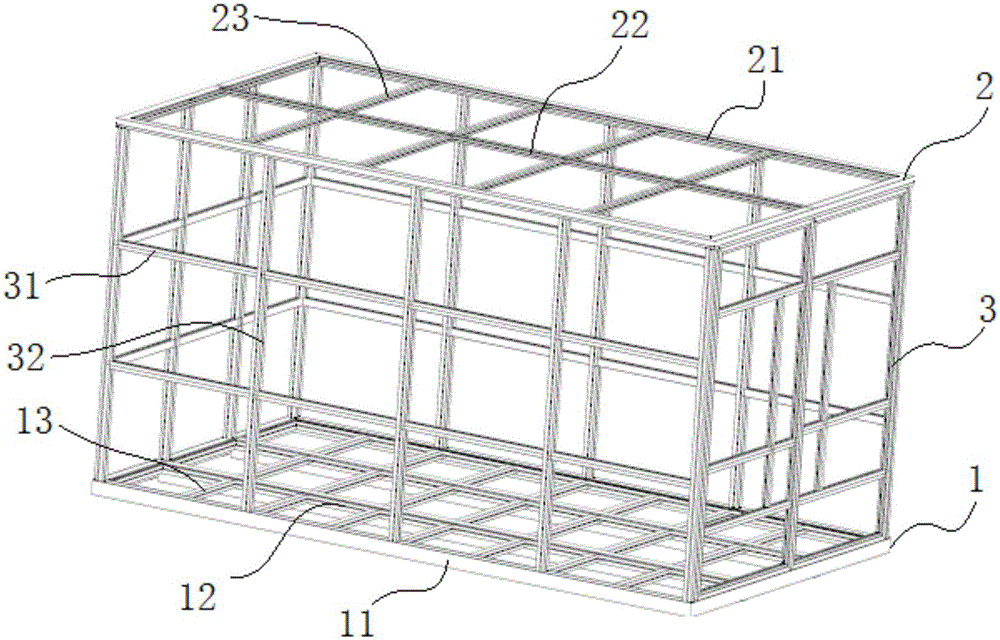

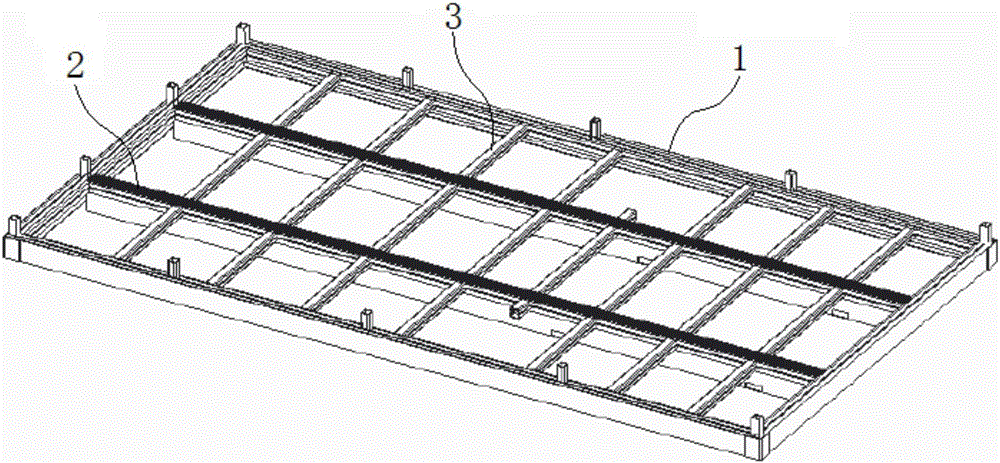

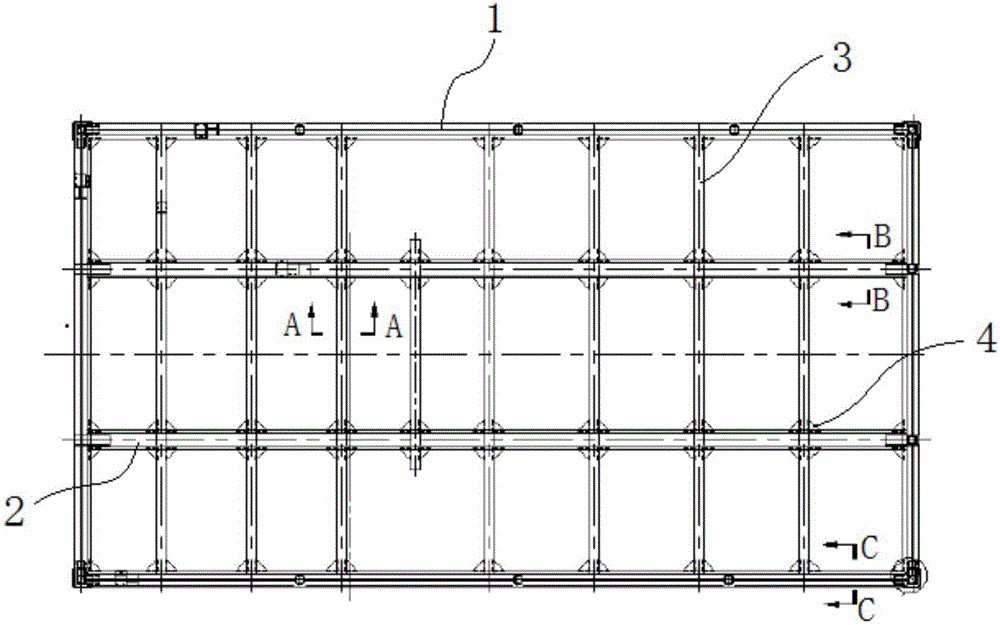

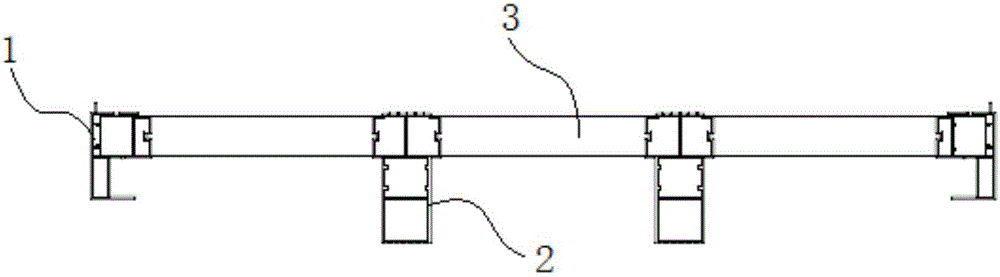

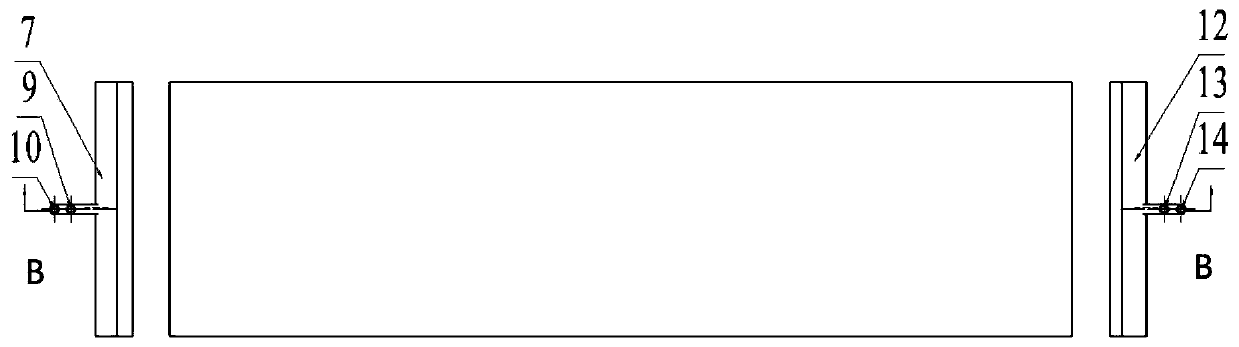

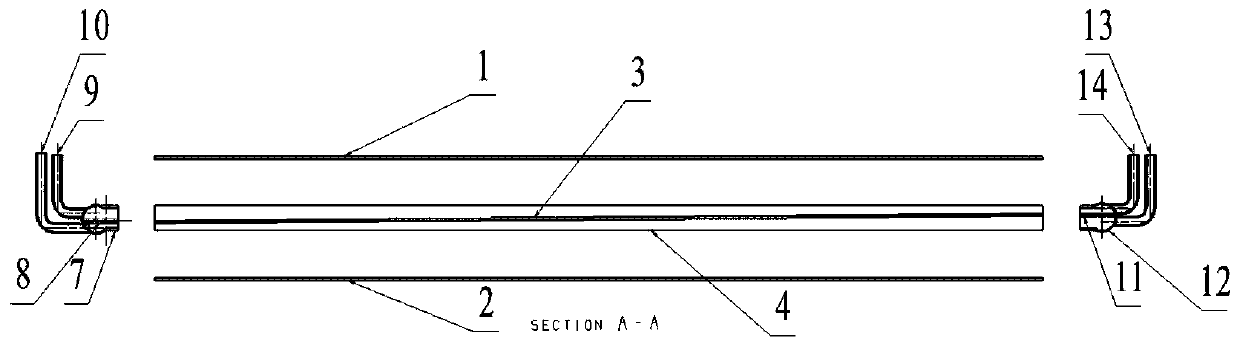

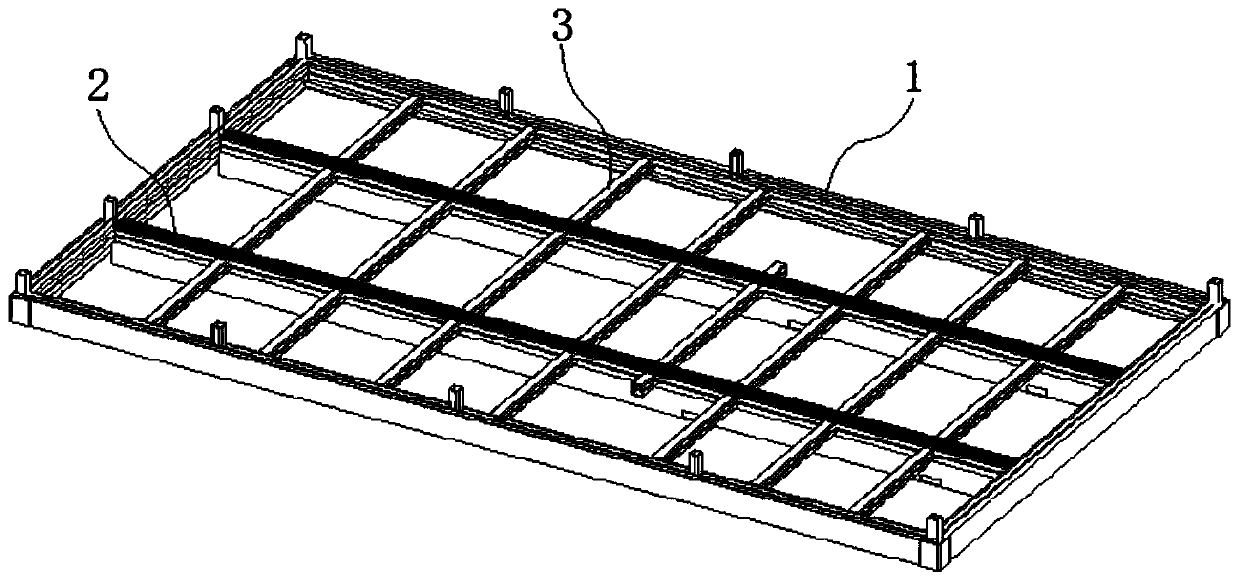

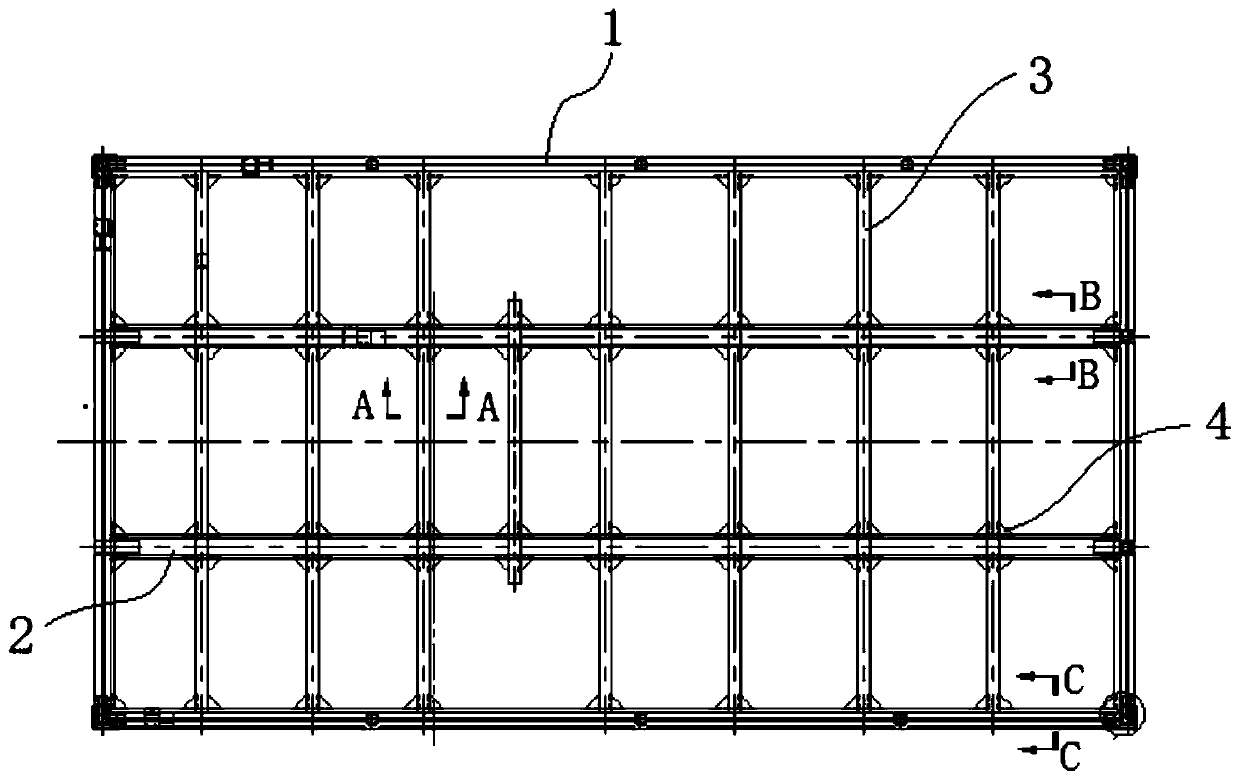

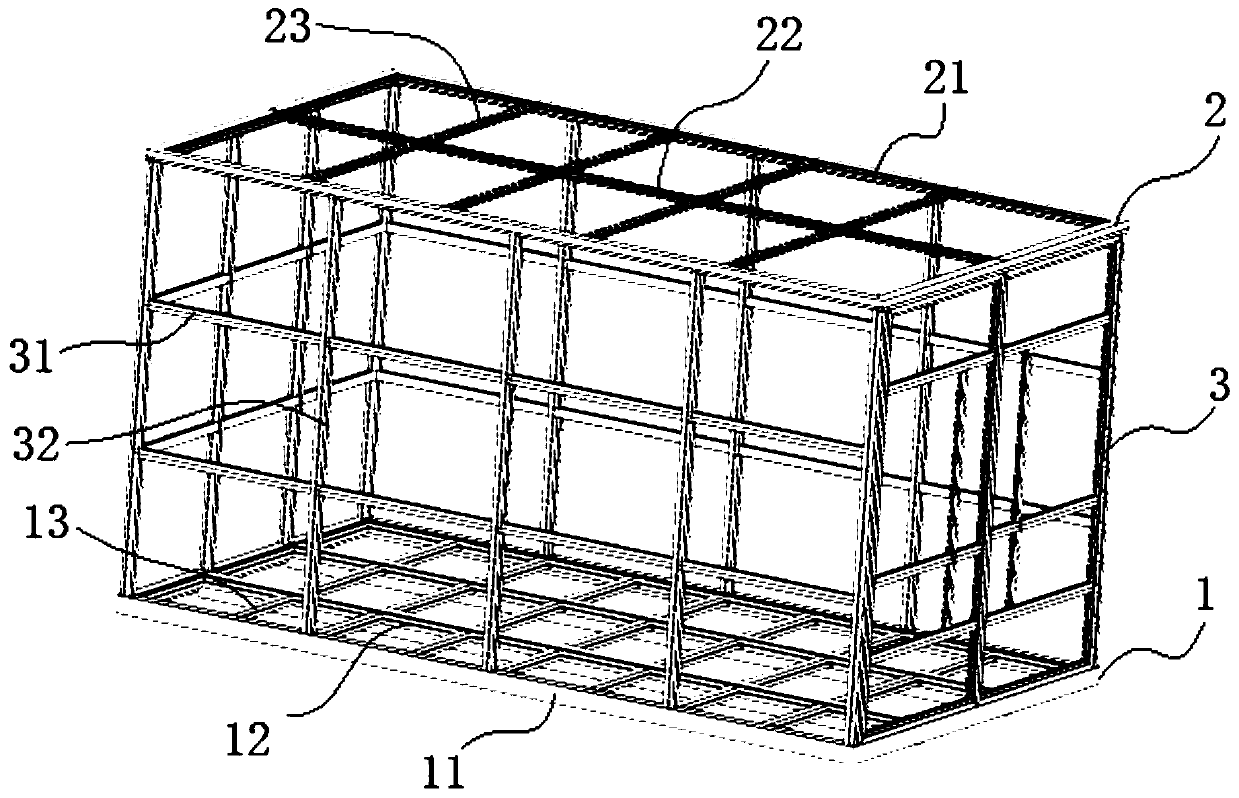

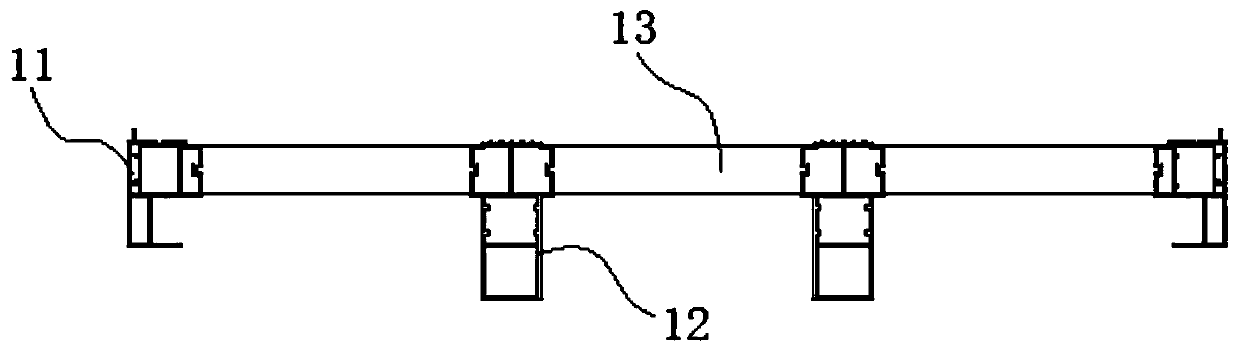

Full-aluminum carriage

ActiveCN106080805AMeet load requirementsPromote lightweight developmentLoading-carrying vehicle superstructuresStructural engineeringAlloy

The invention discloses a full-aluminum carriage. The full-aluminum carriage comprises a carriage framework and an aluminum skin. The carriage framework comprises a bottom edge frame, a sub longitudinal beam, a bottom edge frame transverse beam, a top edge frame and four side frame beams, wherein the bottom edge frame comprises four bottom edge frame beams which are connected with each other to form a rectangle, wherein the two parallel bottom edge frame beams are transverse bottom edge frame beams; and the other two bottom edge frame beams are longitudinal bottom edge frame beams; the bottom edge frame is provided with the sub longitudinal beam; the two ends of the sub longitudinal beam are connected with a transverse bottom edge frame beam in an inserted way; the bottom edge frame is provided with the bottom edge frame transverse beam; the two ends of the bottom edge frame transverse beam are connected with a longitudinal bottom edge frame beam in an inserted way; the bottom edge frame transverse beam is connected with the sub longitudinal beam in an inserted way; the top edge frame comprises four top edge frame beams which are connected with each other to form a rectangle; the corner of the bottom edge frame is connected with the corner of the top edge frame through the side frame beams; and each beam is made of aluminum alloy. According to the invention, as the beams are connected with each other in an inserted way, the carriage framework forms an integrated structure so that the carriage obtains enough rigidity and strength to satisfy loading requirements.

Owner:广西南南铝加工有限公司

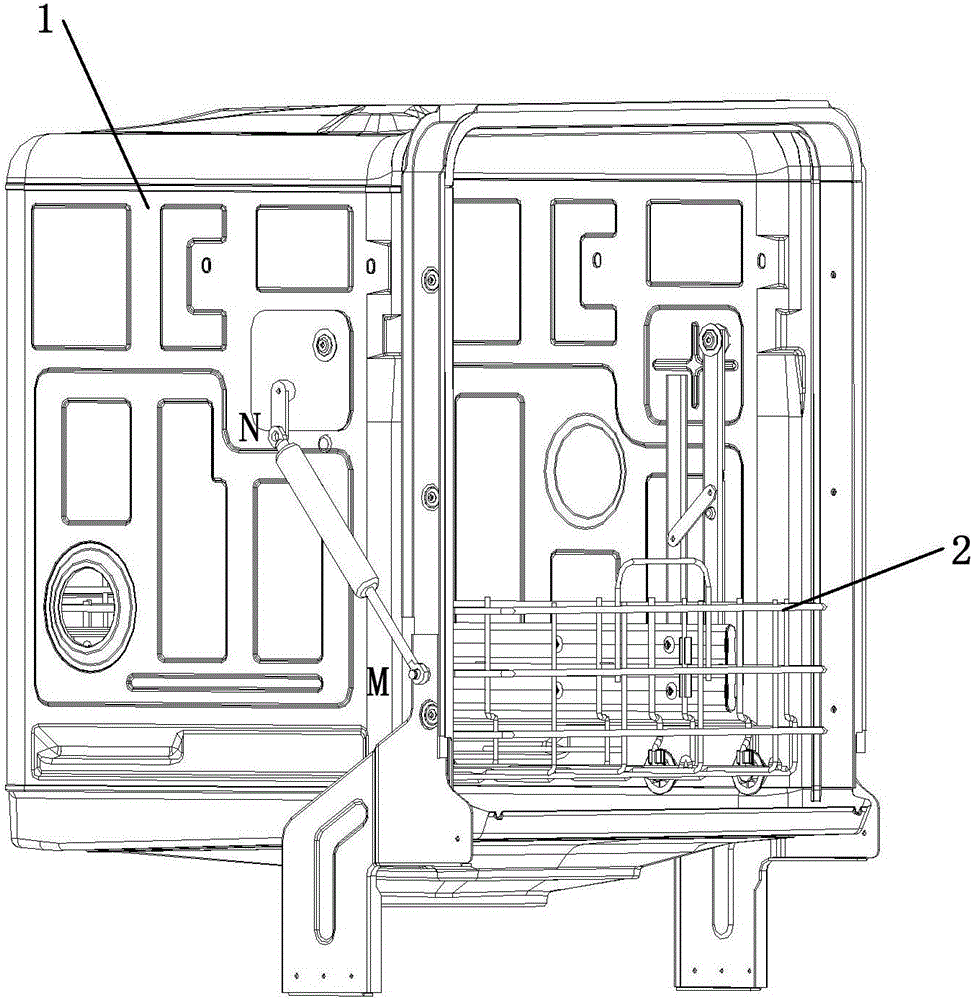

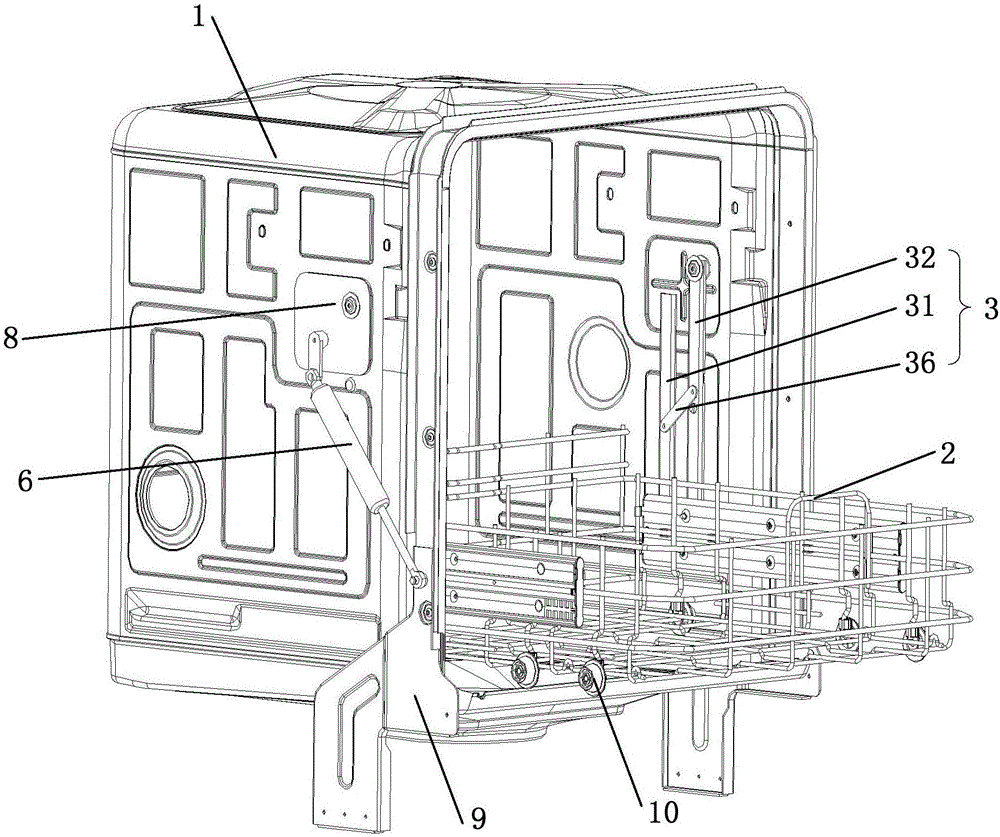

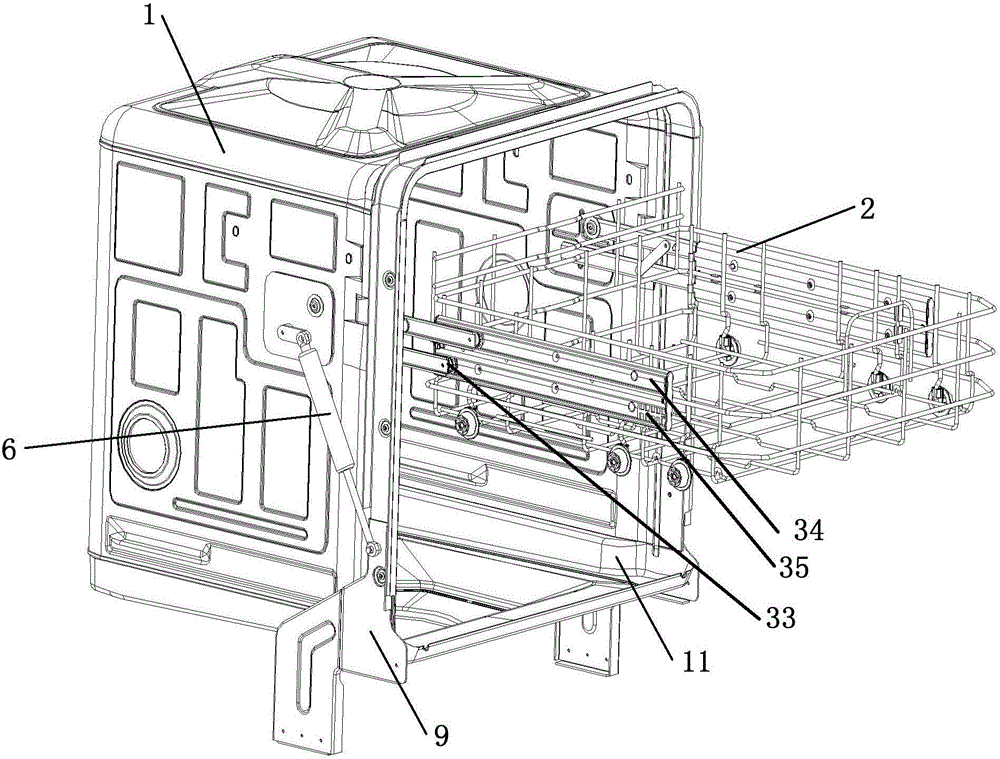

Tableware cleaning machine

InactiveCN106175633AImprove experienceReduce structural complexityTableware washing/rinsing machine detailsMechanical engineeringEngineering

The invention discloses a tableware cleaning machine, relating to the field of kitchen equipment so that convenience of the tableware cleaning machine is improved. The tableware cleaning machine comprises a housing, a tableware basket and a driving mechanism rotatably connected with the housing. The tableware basket is connected with the driving mechanism capable of rotating relative to the housing to lift the tableware basket. By taking the above technical scheme, the tableware basket is upwardly lifted such that the position thereof is lifted. Therefore, operation is more user-friendly and convenience is improved because a user can stand up or take tableware. The experience of the user is improved. In addition, the above mentioned technical scheme utilizes a manual mode to push the tableware basket. Without utilizing a motor and other driving units to drive, the structure complexity of the tableware cleaning machine is greatly reduced and the tableware cleaning machine is beneficial to lightweight development of products.

Owner:GREE ELECTRIC APPLIANCES INC

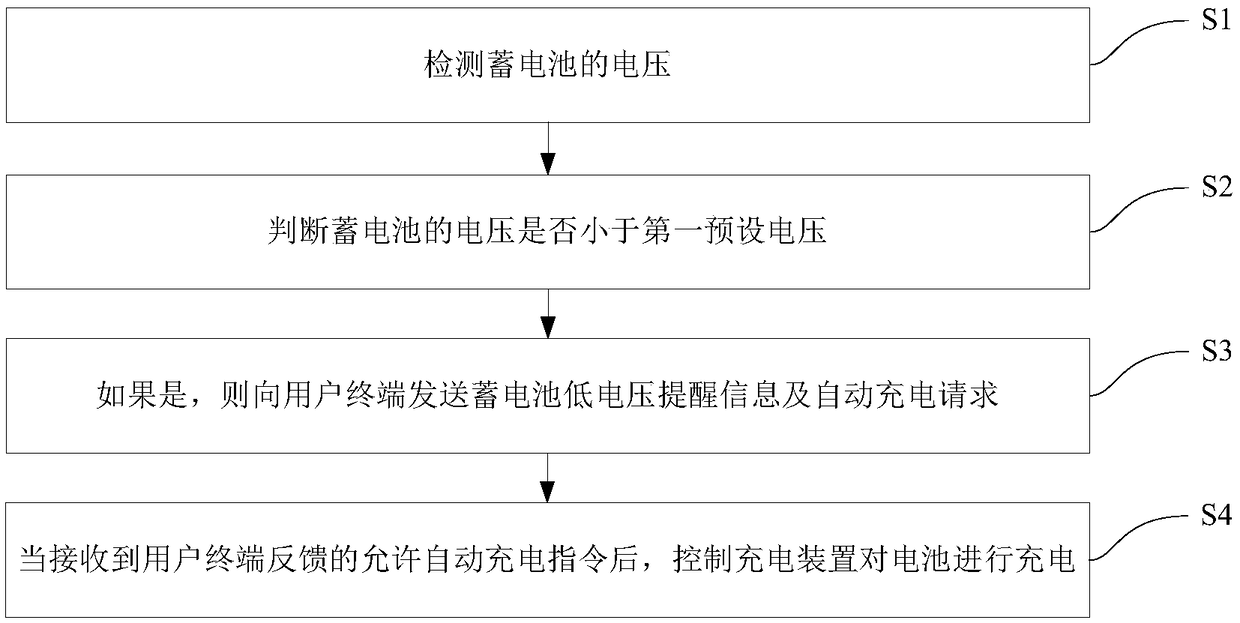

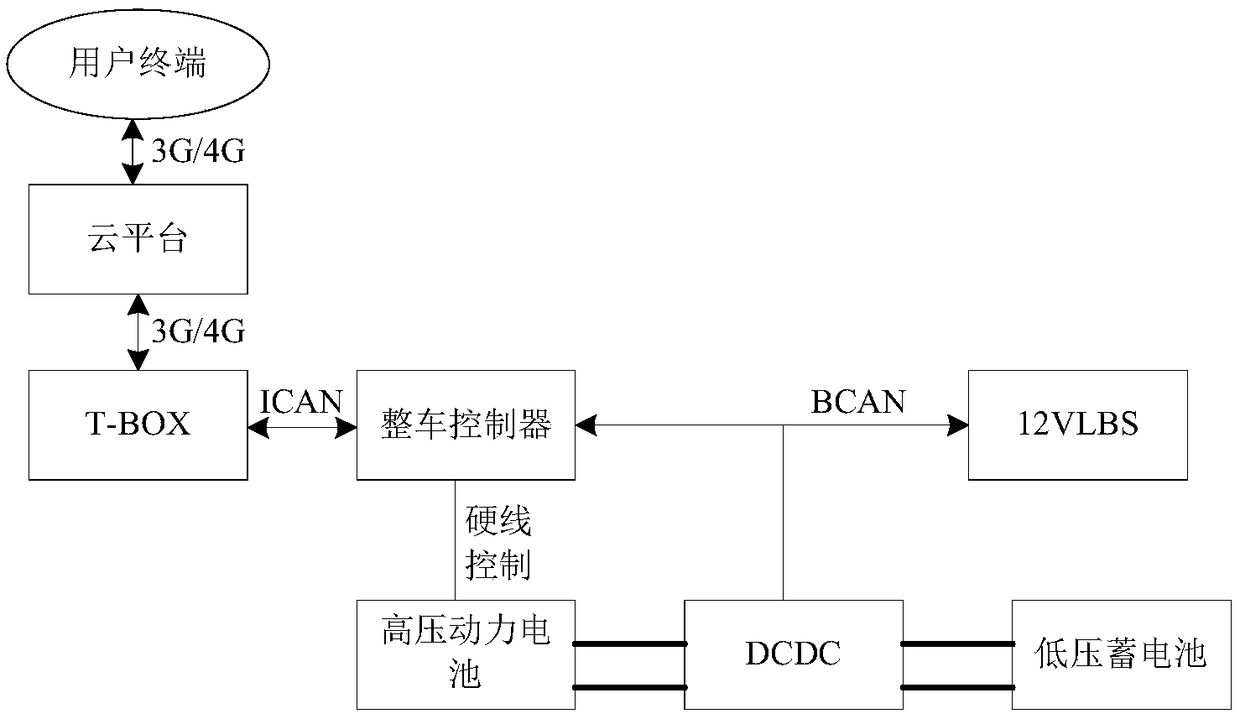

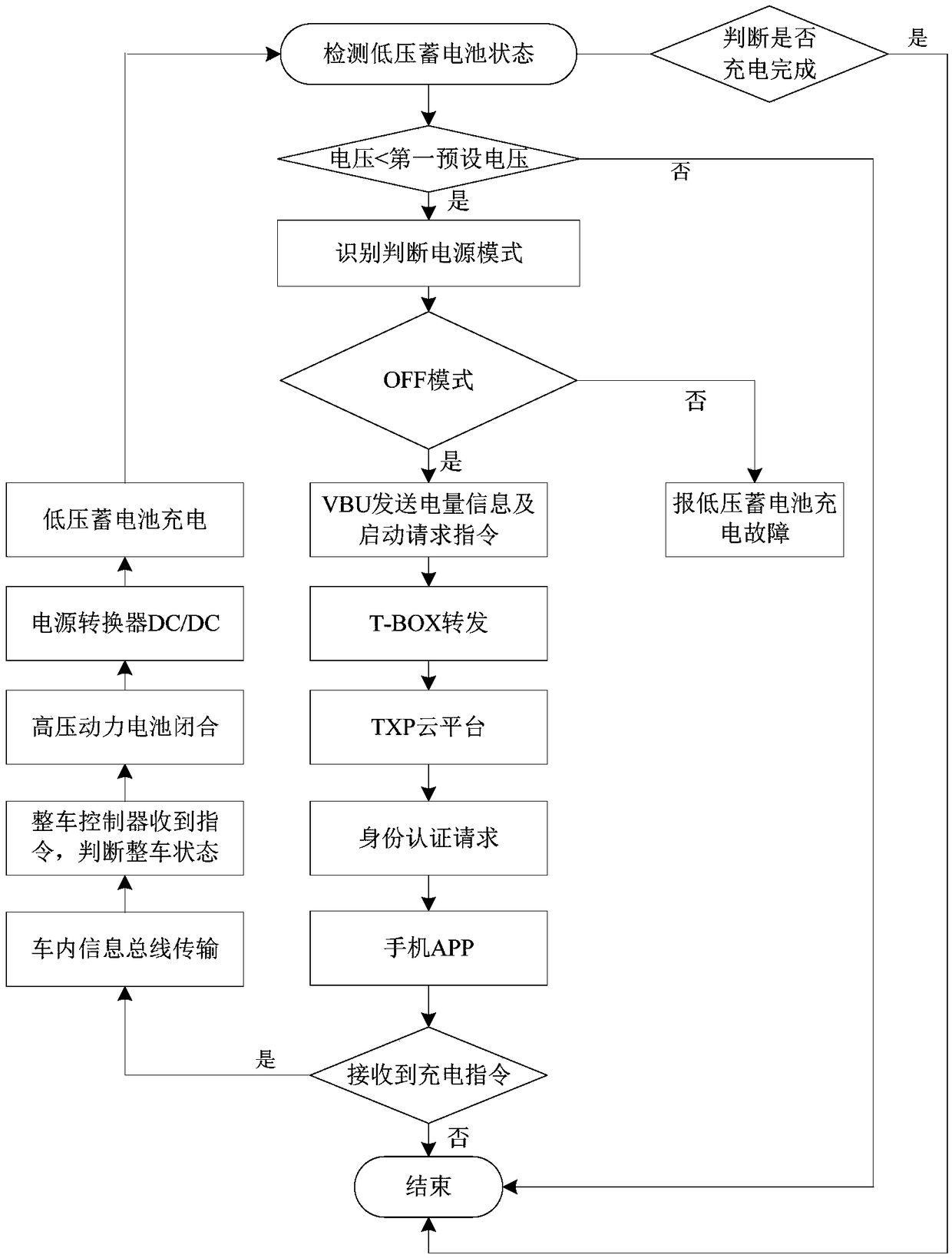

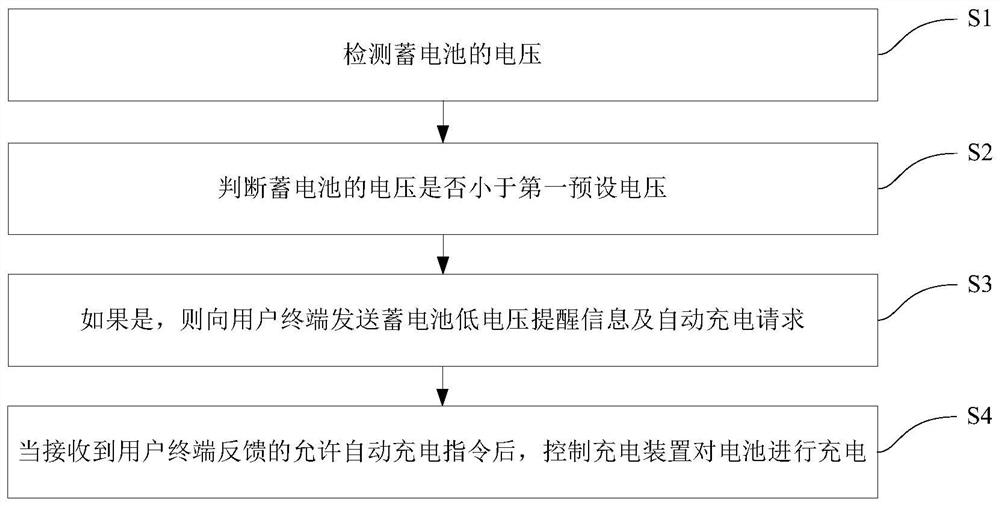

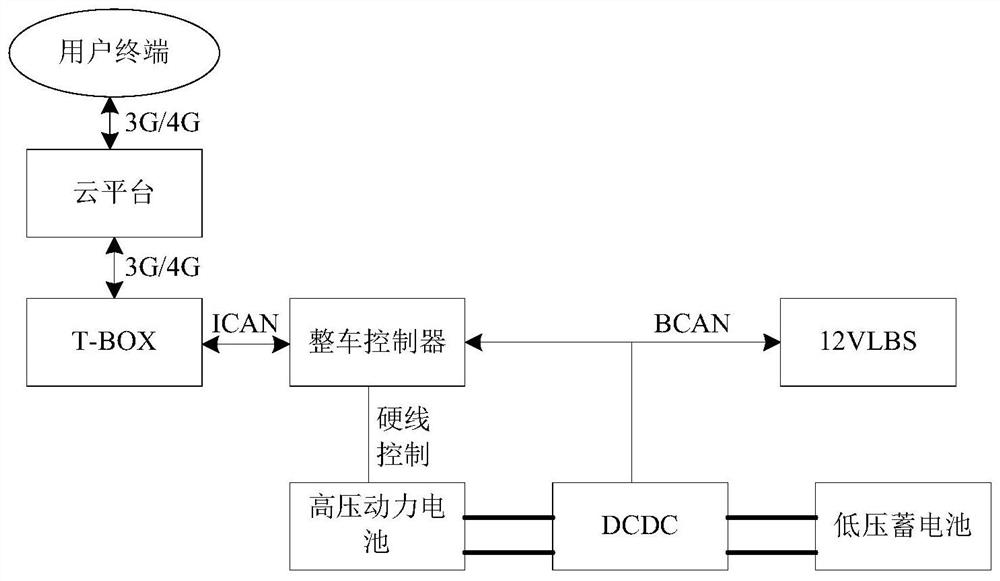

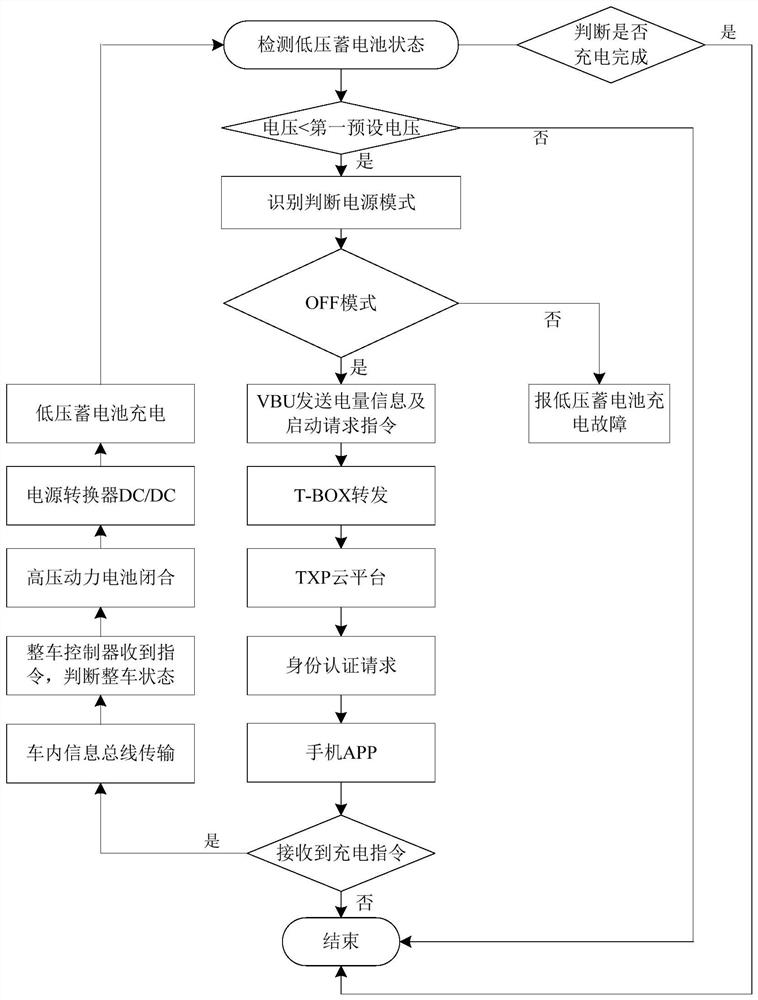

Charging control method and system of electric vehicle, and electric vehicle

ActiveCN109177809AReplenish electricity in timeImprove experienceBatteries circuit arrangementsElectric powerLow voltageElectrical battery

The invention provides a charging control method and system of an electric vehicle, and an electric vehicle. The charging control method comprises the following steps: detecting the voltage of a battery; judging whether the voltage of the battery is less than the first preset voltage; if so, sending a battery low voltage reminder message and an automatic charging request to the user terminal; andafter receiving the instruction allowing automatic charging, fed back by the user terminal, controlling the charging device to charge the battery. The charging control method can send reminding information and charging request to the user when the voltage of the vehicle battery is too low, thereby facilitating the timely supplement of the battery power, avoiding the power deficit phenomenon causedby the long-term parking of the vehicle, greatly facilitating the user, lowering the required cost, and improving the user experience.

Owner:CH AUTO TECH CORP CO LTD

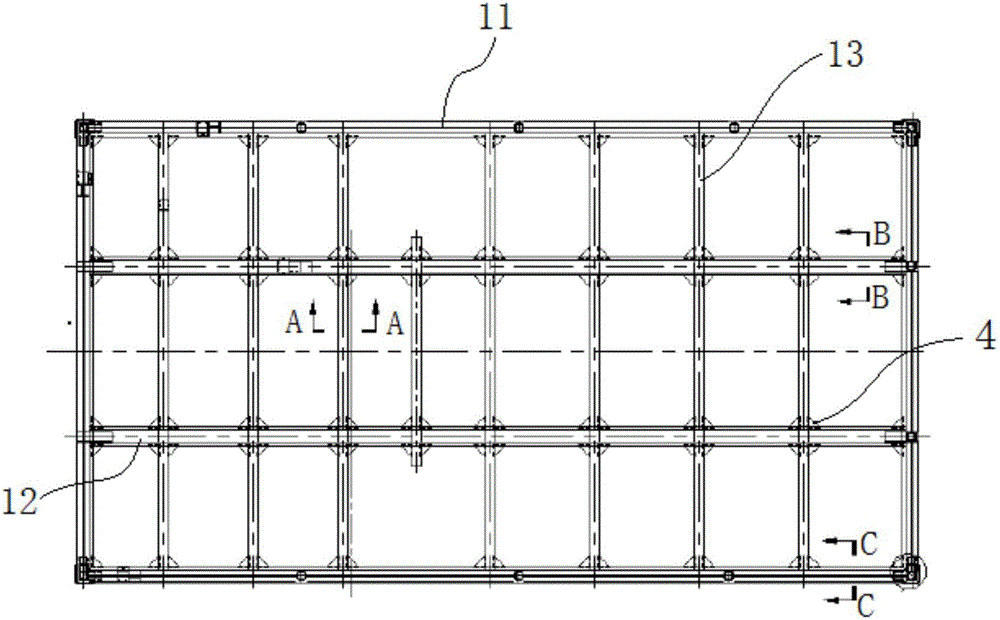

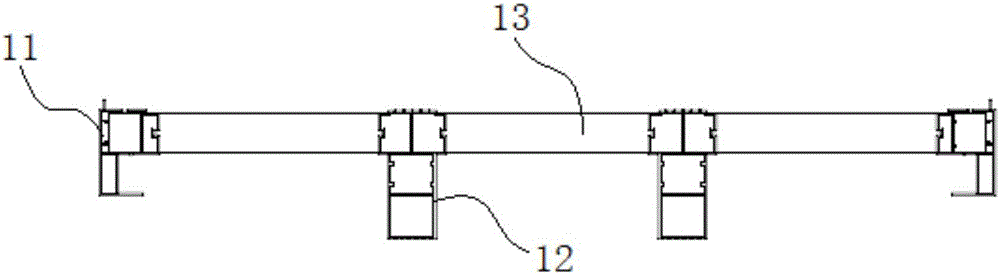

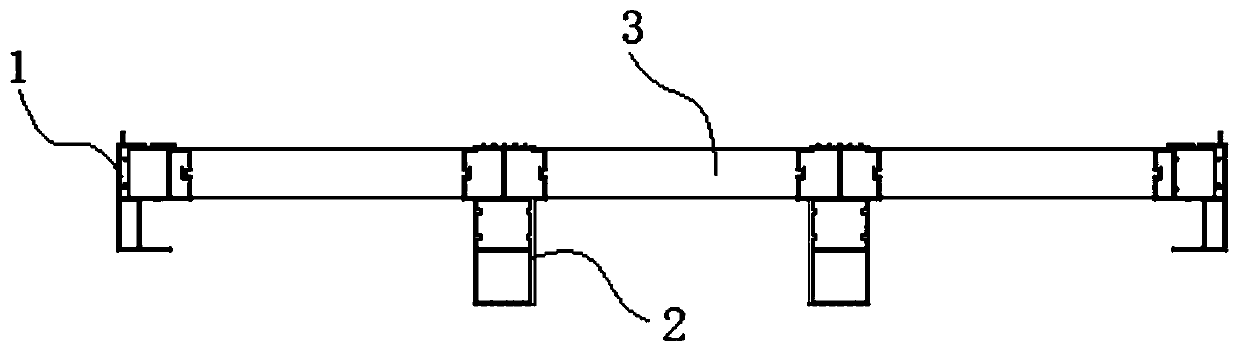

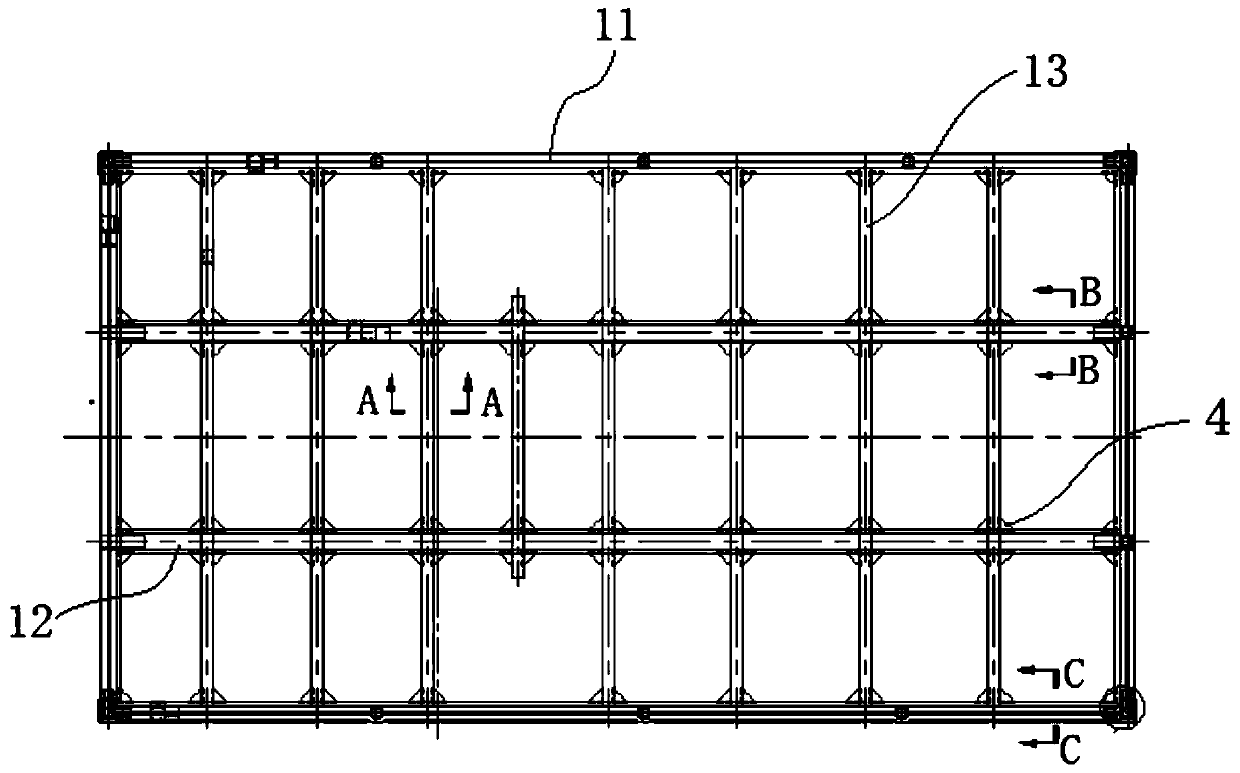

Chassis of full-aluminum carriage

ActiveCN106080806AEasy to manufactureEasy to assembleLoading-carrying vehicle superstructuresAluminium alloyTransverse beam

The invention discloses a chassis of a full-aluminum carriage. The chassis of the full-aluminum carriage comprises a bottom edge frame, sub longitudinal beams and transverse beams, wherein the bottom edge frame comprises four edge frame beams which are connected with each other to form a rectangle, wherein the two parallel edge frame beams are transverse edge frame beams; and the other two edge frame beams are longitudinal edge frame beams; at least one the sub longitudinal beam is arranged in the bottom edge frame; the two ends of the sub longitudinal beam are connected with a transverse edge frame beam in an inserted way; at least one transverse beam is arranged in the bottom edge frame; the two ends of the transverse beam are connected with a longitudinal edge frame beam in an inserted way; each transverse beam is connected with each sub longitudinal beam in an inserted way at the crossed part; and the edge frame beams, the sub longitudinal beams and the transverse beams are all made of aluminum alloys. According to the invention, as the beams are connected with each other in an inserted way, the carriage framework forms an integrated structure so that the carriage obtains enough rigidity and strength to satisfy loading requirements. According to the invention, as the sub longitudinal beams are connected with the transverse beams in an inserted way, the end parts of the sub longitudinal beams are inserted in the transverse edge frame beams and the end parts of the transverse beams are inserted in the longitudinal edge frame beams, the chassis forms an integrated structure so that the chassis obtains enough rigidity and strength to satisfy loading requirements of the carriage.

Owner:广西南南铝加工有限公司

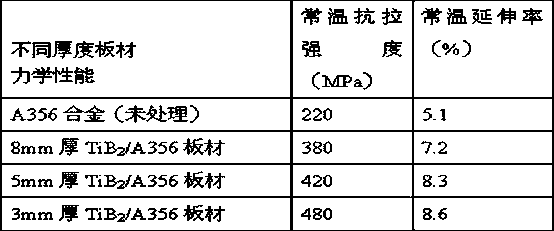

Preparing process of high-performance TiB2/A356 composite panel

The invention relates to a preparing process of an aluminum base composite panel, in particular to a preparing process of a high-strength TiB2 particle enhanced aluminum base composite panel. The process specifically includes the steps of placing an A356 alloy material in a graphite crucible to be heated to a certain temperature, adding a certain amount of dry potassium fluoborate to molten A356 alloy for reaction for a certain period of time, cooling the alloy to a certain temperature after the reaction ends, casting the alloy into an extrusion die, cooling the die to a certain temperature and then directly conducting extraction by a certain mode, and directly conducting rolling by a certain mode after extrusion ends to obtain the panel. The TiB2 particle enhanced A356 composite panel prepared through the process contains small base body crystal particles and few impurities and is uniform in particle distribution, the tensile strength of the panel is greatly improved, and plasticity is also improved.

Owner:镇江海利新材料科技有限公司 +1

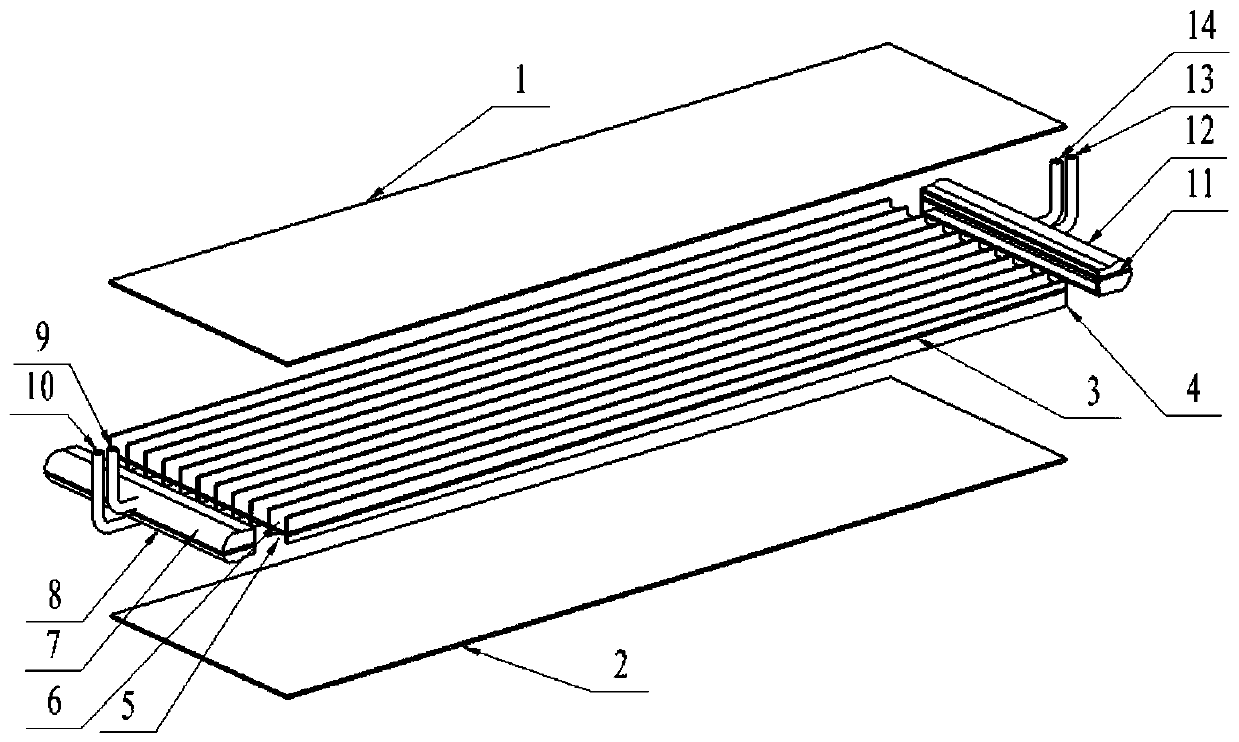

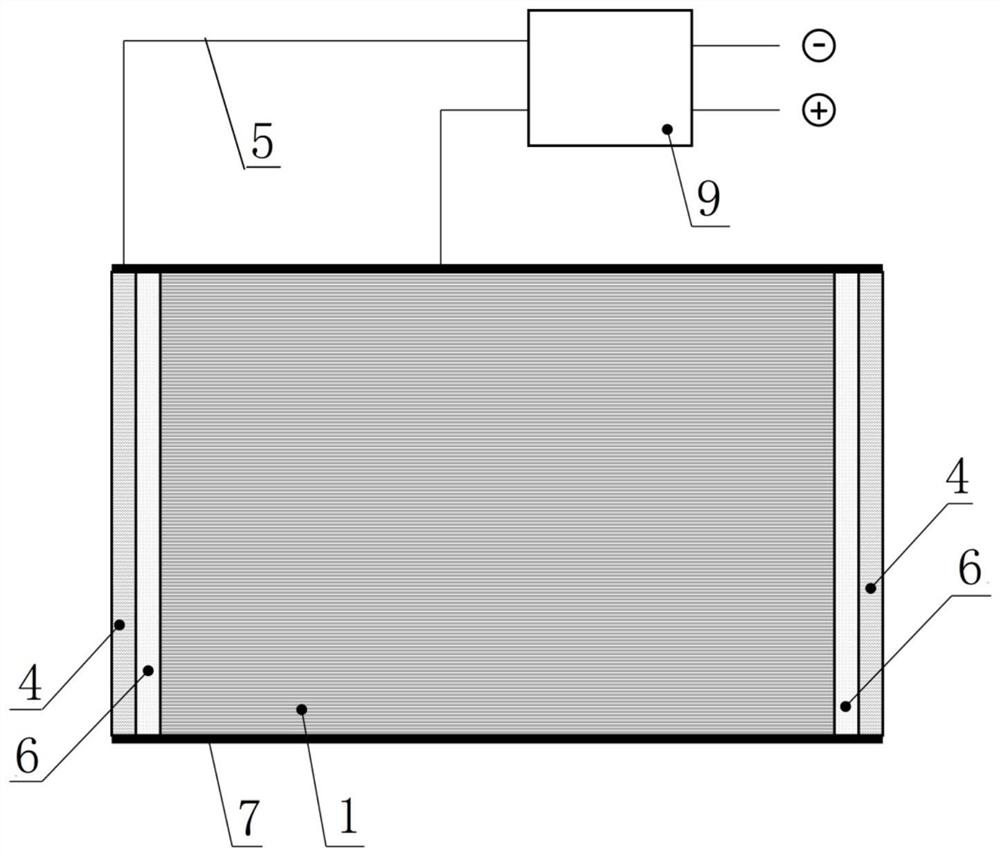

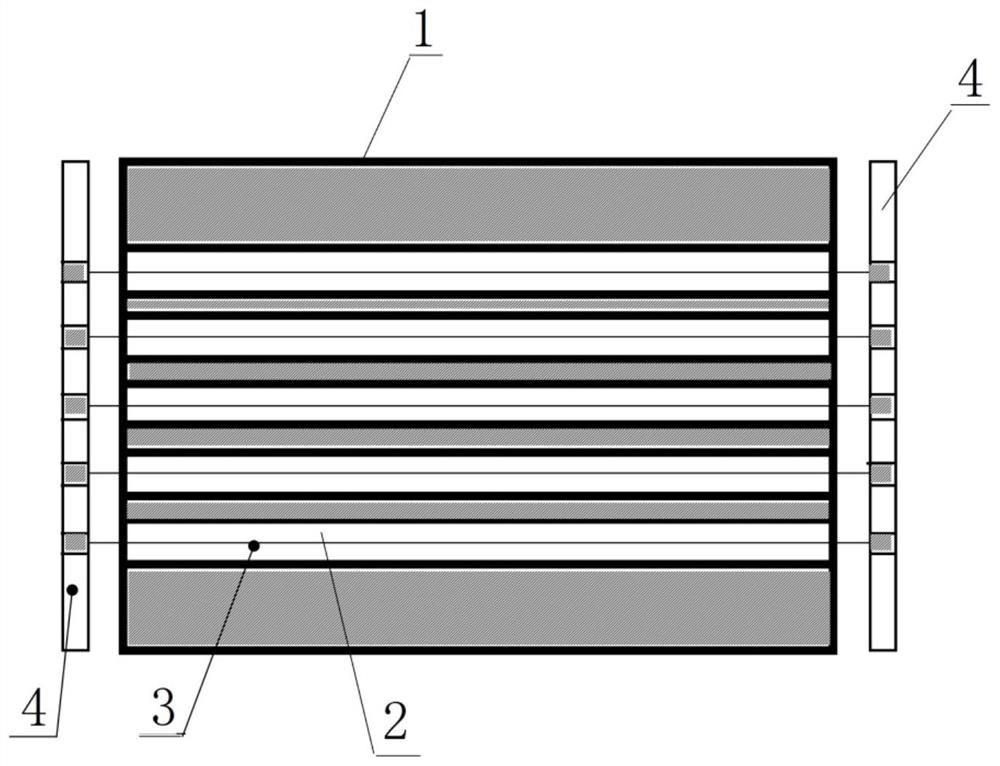

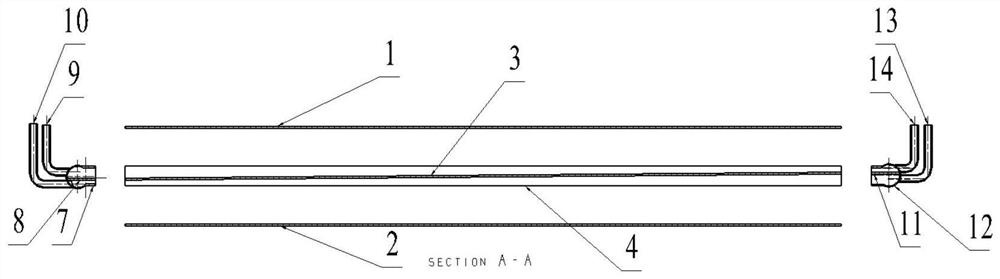

Double-sided working liquid cooling plate with tapered sections on two sides

ActiveCN110890605AReduce in quantityReduce system space occupation and power consumptionSecondary cellsPhysicsElectrical battery

The invention relates to a double-sided working liquid cooling plate with tapered sections on two sides. The heat exchanger comprises an upper side cover plate, a lower side cover plate, a plate body,a left flow collecting pipe and a right flow collecting pipe. The upper side cover plate is arranged above the plate body; the lower side cover plate is arranged below the plate body, the left flow collecting pipe and the right flow collecting pipe are arranged on the left side and the right side of the plate body respectively, the plate body comprises two layers of micro-channel partition plates, the flow directions of cooling liquid in the upper layer of micro-channel partition plates and the lower layer of micro-channel partition plates are opposite, and the sectional areas of the two layers of micro-channel partition plates in the liquid flowing direction are gradually reduced. According to the double-sided working liquid cooling plate with the tapered sections on the two sides, the battery module can be cooled more uniformly, Meanwhile, the double sides can work at the same time. Because one liquid cooling plate can cool two batteries at the same time, the total number of the liquid cooling plates required by the battery system is greatly reduced, the space occupation and electric energy consumption of the system can be greatly reduced, and the development of light weight ofa new energy automobile is facilitated.

Owner:JIANGSU UNIV

Chassis of an all-aluminum carriage

ActiveCN106080806BEasy to manufactureEasy to assembleLoading-carrying vehicle superstructuresAlloyEngineering

Owner:广西南南铝加工有限公司

A kind of yield strength 960mpa automobile frame steel and its production method

The invention discloses automobile beam steel with 960 MPa yield strength and a production method thereof. The automobile beam steel comprises the following chemical components in percent by weight: 0.12-0.14 percent of C, 0.15-0.35 percent of Si, 1.2-1.5 percent of Mn, 0.02-0.04 percent of Nb, 0.3-0.5 percent of Mo, 0.08-0.15 percent of V, 0.01-0.04 percent of Ti, 0.01-0.06 percent of Al, 0.4-0.6 percent of Cr, 0.0015-0.0025 percent of B, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.008 percent of N, and the balance of Fe and inevitable impurities. C and Mn with low content are adopted, the separation strengthening effects of V, Nb and Ti are sufficiently utilized, and besides, a certain amount of Mo, a certain amount of Cr and a certain amount of B are added to control the heat treatment structure state, so that a fine and uniform tempering structure is obtained, the steel has high toughness, high welding performance and high low-temperature impact toughness, the safety performance of a vehicle is improved, the light-weight development of the vehicle is facilitated, and the technical problems that in the prior art, since the low-temperature impact toughness of steel is low, the potential safety hazards of a vehicle are caused, and the lightweight development of the vehicle is limited since the strength of the steel is low.

Owner:SHOUGANG CORPORATION +1

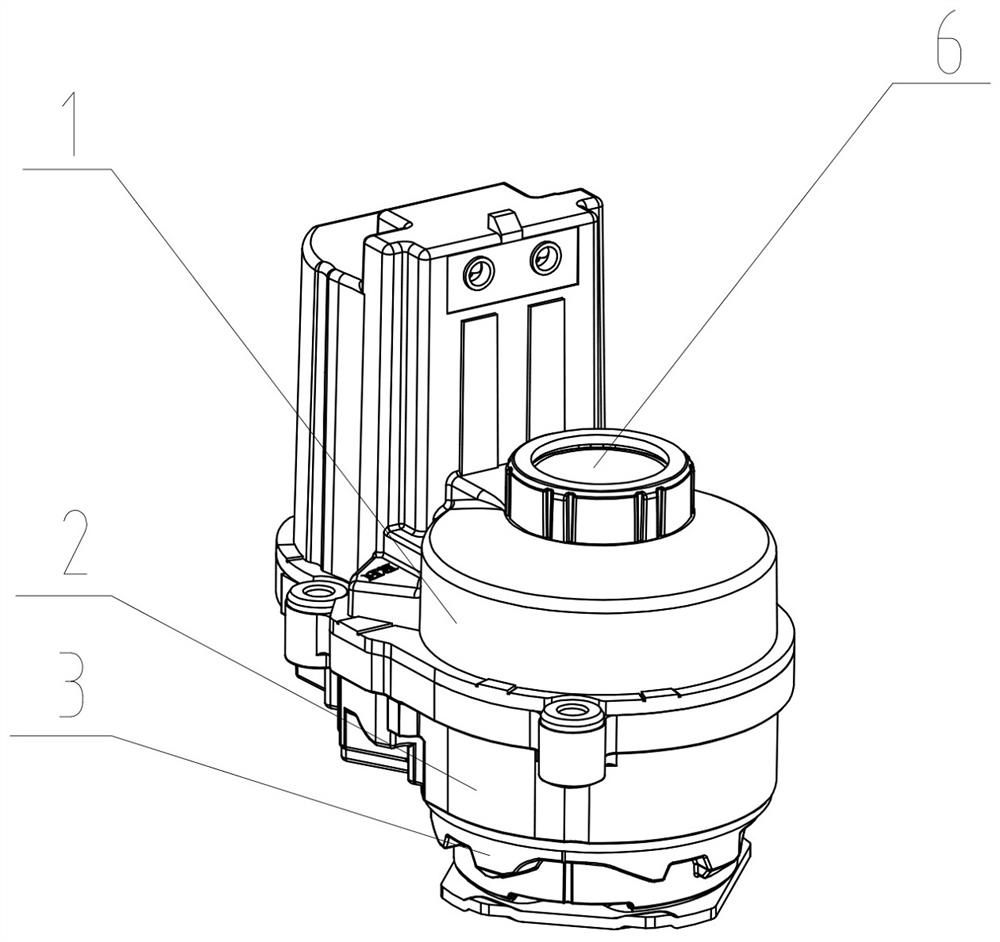

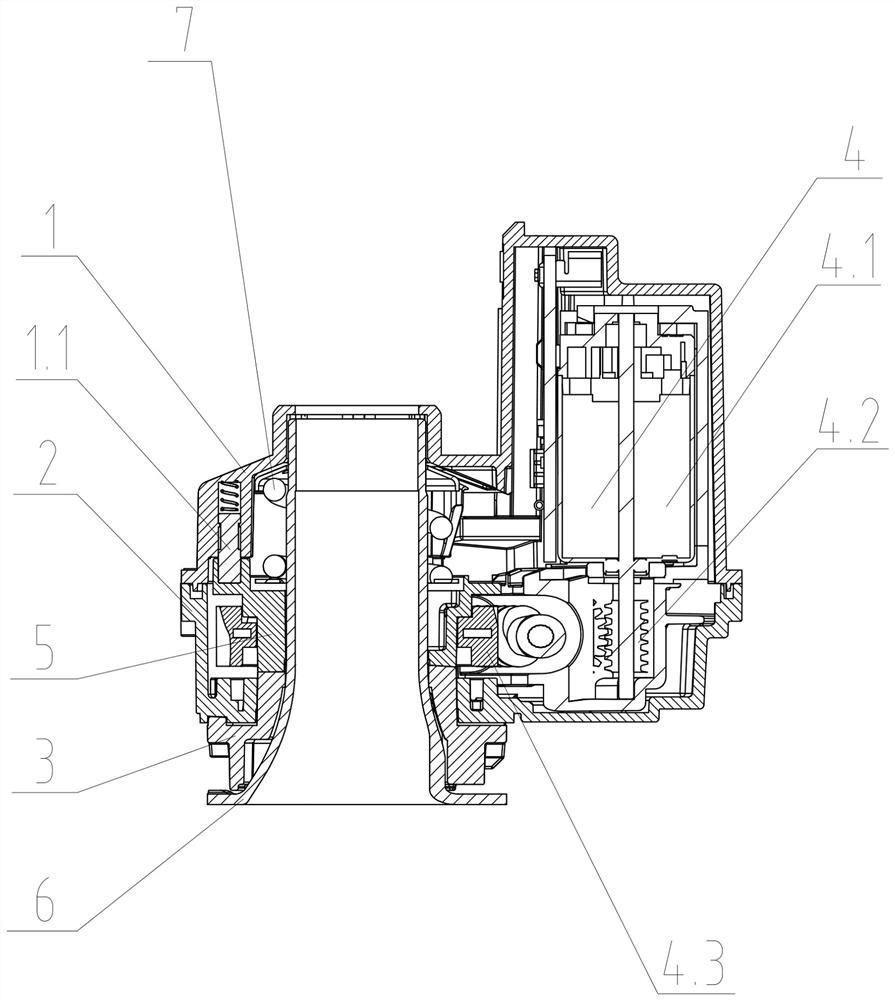

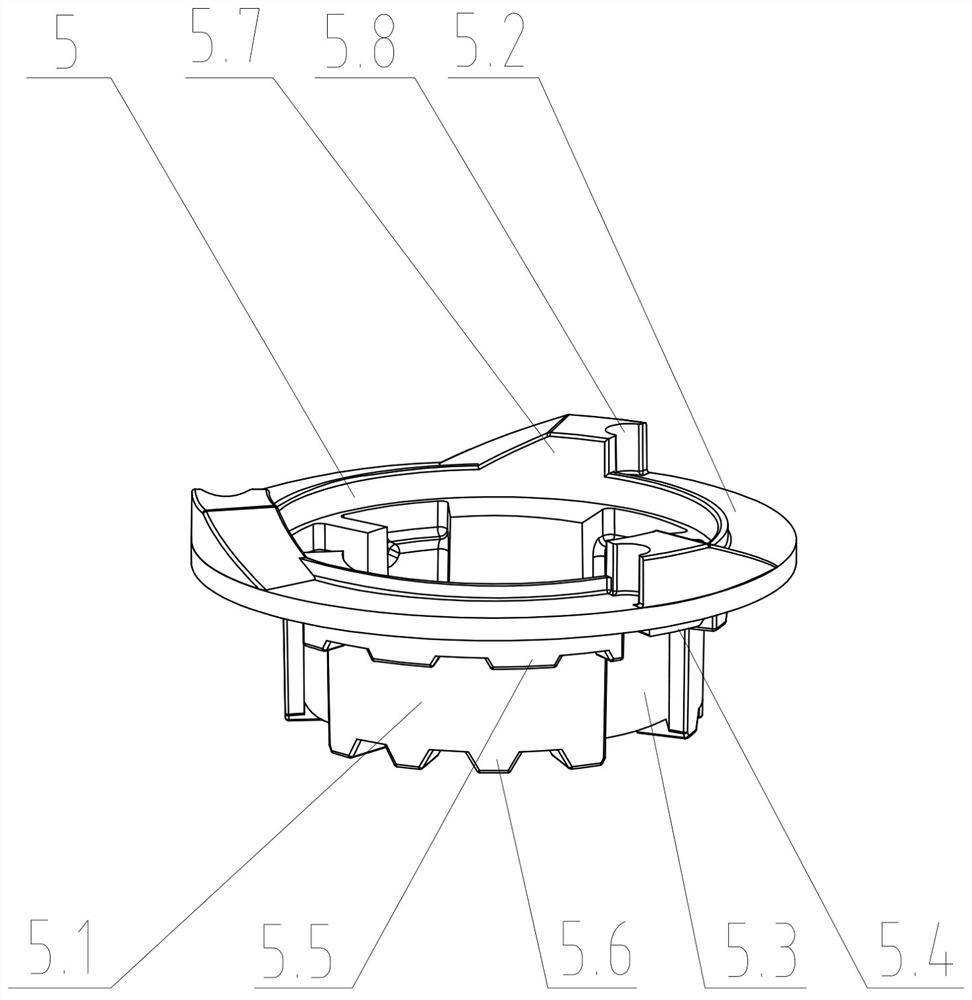

Electric folding device for outside rear-view mirror of automobile

The invention discloses an electric folding device for an outside rear-view mirror of an automobile. The electric folding device comprises a centralized connecting piece; the centralized connecting piece is provided with a mounting part allowing a driving gear to slide in the circumferential direction; a limiting seat is integrally arranged on the upper portion of the mounting part; a spring abutsagainst the upper end of the limiting seat; the driving gear abuts against the position between the limiting seat and a foundation support, and in the initial state, reserved gaps are formed betweenthe driving gear and the limiting seat as well as between the driving gear and the foundation support; and a foundation support cam assembly and a base cam assembly are driven by an electric drive unit to gradually slide relative to each other, and in the process, the reserved gap is gradually eliminated along with upward lifting of the foundation support until the foundation support cam assemblyabuts against the base cam assembly. The electric folding device for the outside rear-view mirror of the automobile can smoothly achieve the lifting function, has relatively low requirements for the bearing capacity of a gear, and is suitable for lightweight development and relatively low in cost.

Owner:NINGBO JINGCHENG CAR IND

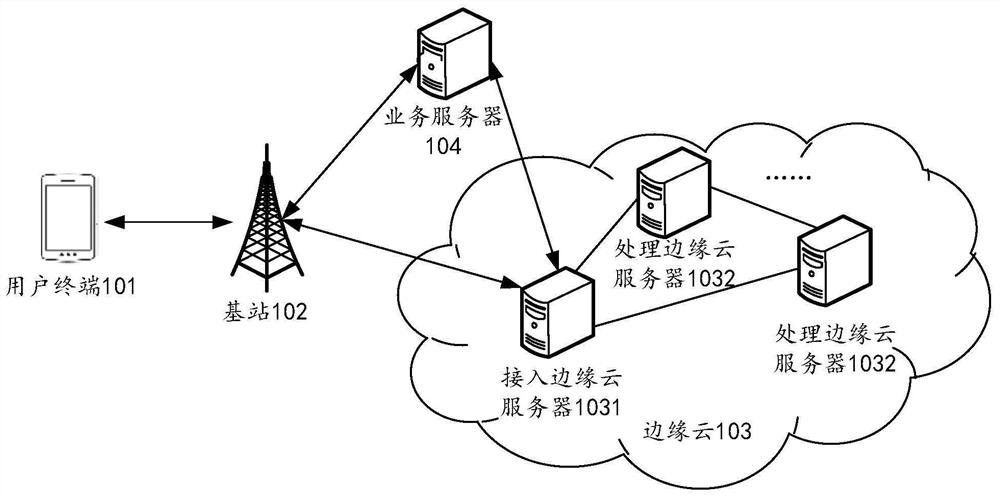

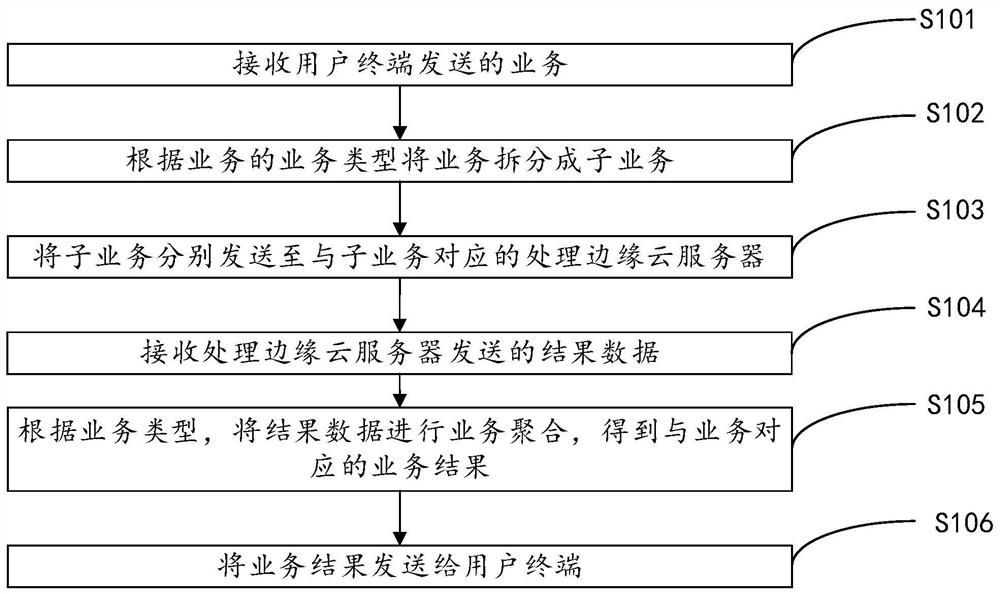

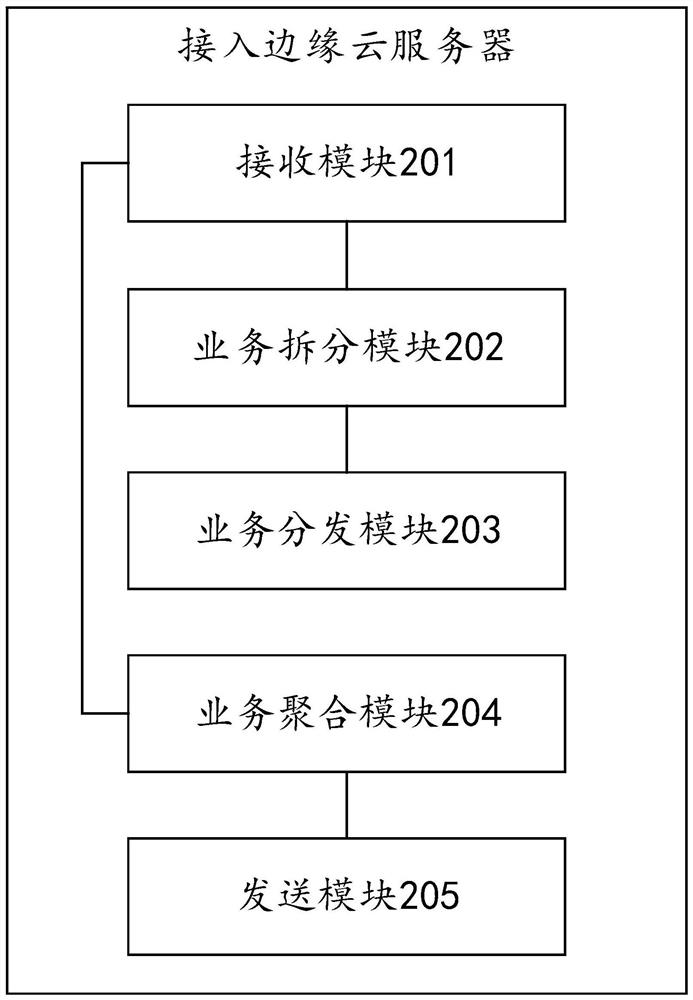

Service processing method, access edge cloud server and service processing system

PendingCN114513506AGuaranteed LatencyPromote lightweight developmentTransmissionEngineeringDistributed computing

The invention provides a service processing method, an access edge cloud server and a service processing system, relates to the technical field of cloud computing, and can ensure service time delay and experience, relieve terminal processing pressure and save precious processing resources of an edge network to a certain extent when processing complex services. The method comprises the following steps: an access edge cloud server receives a service sent by a user terminal; the access edge cloud server splits the service into sub-services according to the service type of the service; the access edge cloud server sends the sub-services to processing edge cloud servers corresponding to the sub-services respectively; the access edge cloud server receives result data sent by the processing edge cloud server; according to the service type, the access edge cloud server performs service aggregation on the result data to obtain a service result corresponding to the service; and the access edge cloud server sends the service result to a user terminal.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

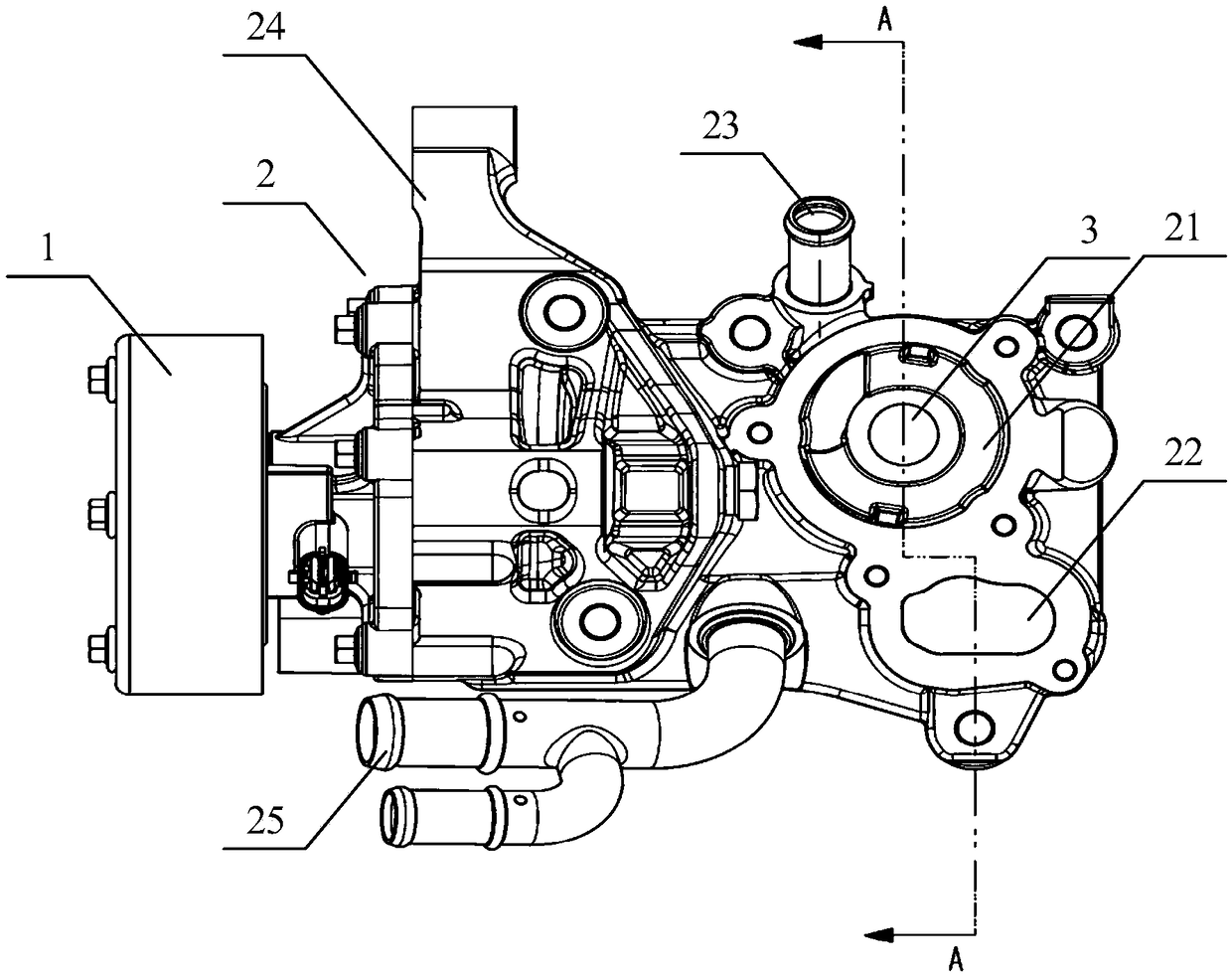

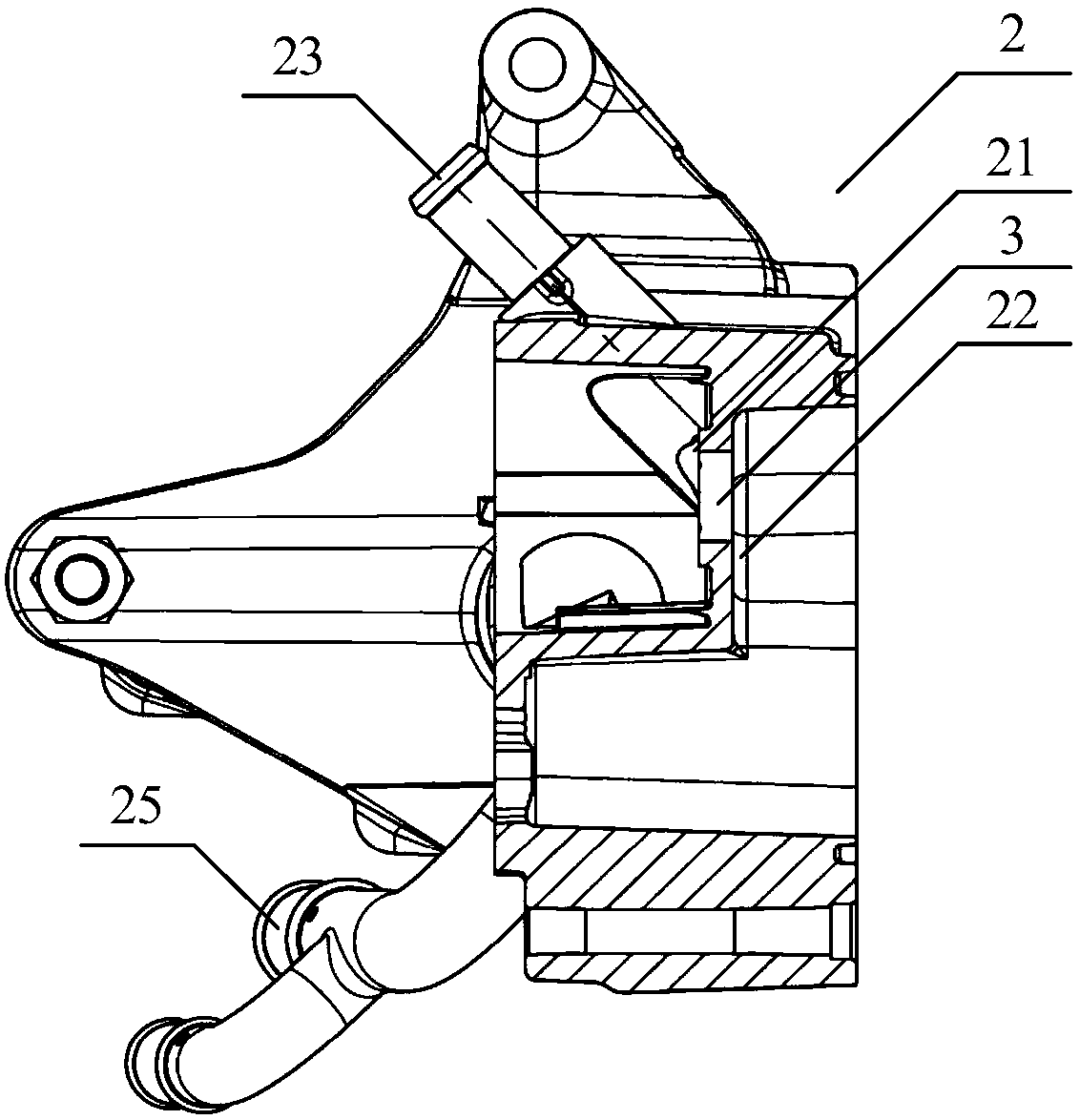

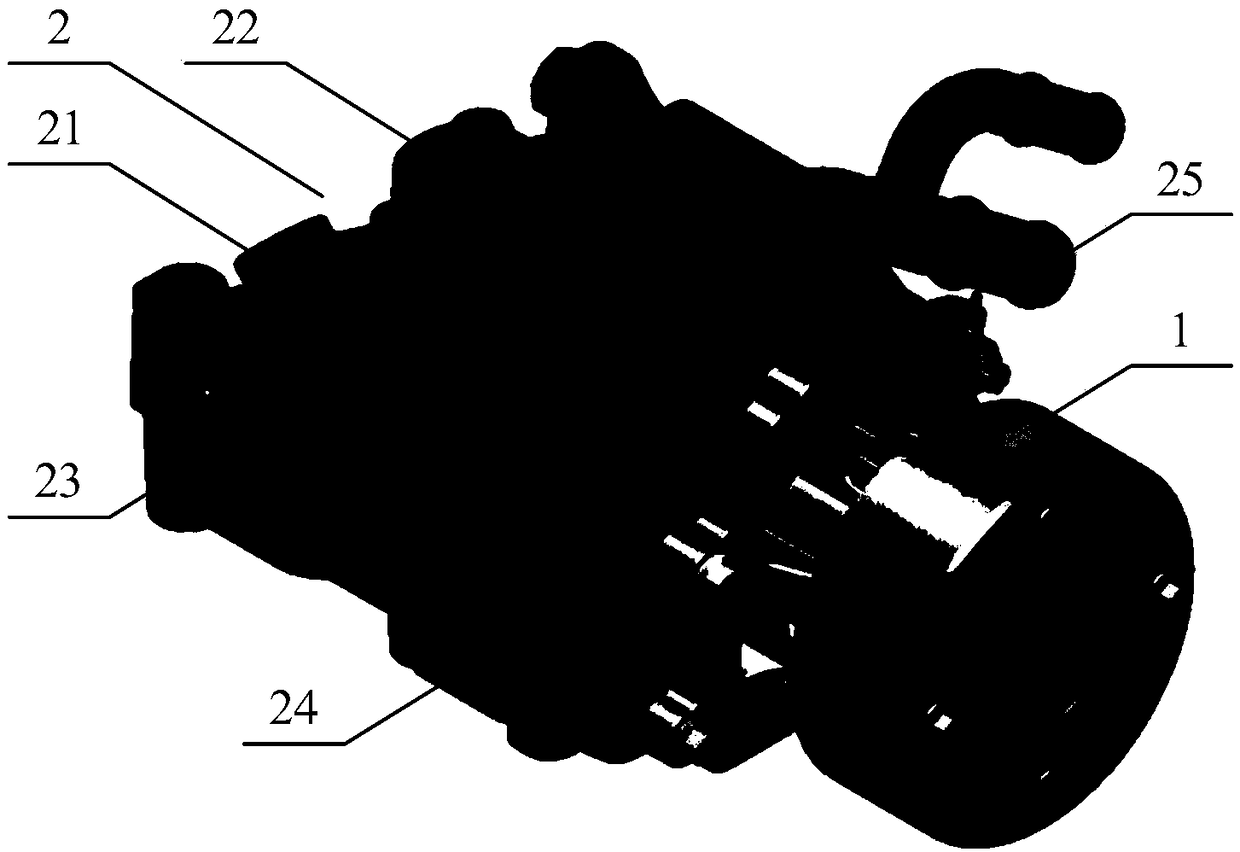

Water pump assembly, cooling system, engine and automobile

ActiveCN109236451ASmall footprintReduce weightMachines/enginesEngine cooling apparatusThermostatElectric generator

The invention discloses a water pump assembly, a cooling system, an engine and an automobile, and belongs to the technical field of automobiles. The water pump assembly comprises a water pump and a water pump shell, wherein the water pump is arranged on the water pump shell, and a channel communicated with a water outlet of the water pump is arranged on the water pump shell; the water pump shell is provided with an engine water inlet, an engine water outlet, an engine oil cooler water inlet and an electric generator bracket for installing the electric generator; a minor-cycle pipeline is arranged between the water inlet of the engine and the water outlet of the engine; a thermostat is arranged at the water inlet of the engine; the water inlet of the engine is respectively connected with afirst pipe orifice of the minor-cycle pipeline and a water outlet of the radiator, and the water outlet of the engine is respectively connected with a second pipe orifice of the minor-cycle pipeline and the water inlet of the radiator. According to the water pump assembly, the cooling system, the engine and the automobile, the weight of the engine can be reduced, and the light weight development of the engine is facilitated.

Owner:CHERY AUTOMOBILE CO LTD

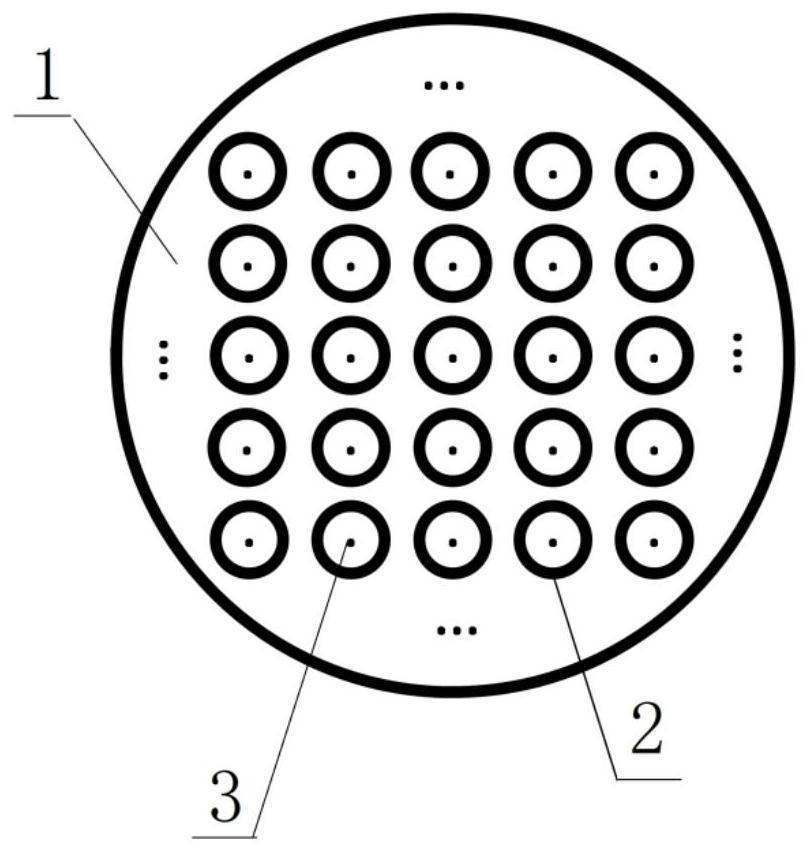

Automobile exhaust particulate matter adsorption device

PendingCN112879124AImprove removal efficiencyReduce the impactExhaust apparatusSilencing apparatusAutomotive engineeringBack pressure

The invention relates to the field of automobile exhaust treatment, and discloses an automobile exhaust particulate matter adsorption device, which comprises a particle collector, a plurality of first vent holes are arranged in the particle collector, and discharge wires which are not in contact with the inner walls of the first vent holes penetrate through the vent holes; the outer portions of the two end faces of the particle collector are each provided with a discharge wire fixing plate for fixing the ends of the discharge wires; gaps are reserved between the end face of the particle collector and the discharge wire fixing plates; the discharge wire fixing plates are of a frame structure, and the discharge wires a re fixedly connected to the discharge wire fixing plates; and the particle collector and the discharge wire fixing plates are respectively connected with positive and negative electrodes of a power supply through wires. According to the automobile exhaust particulate matter adsorption device provided by the invention, the exhaust back pressure of an engine is not increased while the high automobile exhaust particulate matter removal efficiency is guaranteed, and the influence on the performance of the engine is reduced.

Owner:DONGFENG MOTOR GRP

Hybrid laminate structure of new energy automobile battery shell and preparation method

InactiveCN114801364AReduce in quantityImprove integration efficiencySynthetic resin layered productsLaminationAutomotive batteryNew energy

The invention discloses a hybrid laminate structure of a new energy automobile battery shell and a preparation method thereof, based on the characteristics of a fiber-metal hybrid laminate structure, a hybrid laminate structure of an upper cover of the battery shell and a hybrid laminate structure of a box bottom are designed, and the mass of the battery shell is reduced. Preparation-forming integration of the battery pack is completed through a hot mold pressing process, and one-time forming of a complex structure in the shell can be achieved. While the development requirements of light weight and high strength of the battery shell are met, an integrated forming technology is adopted, the welding and riveting times and the processing procedures are reduced, and the integrity and the production efficiency of the battery shell are greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

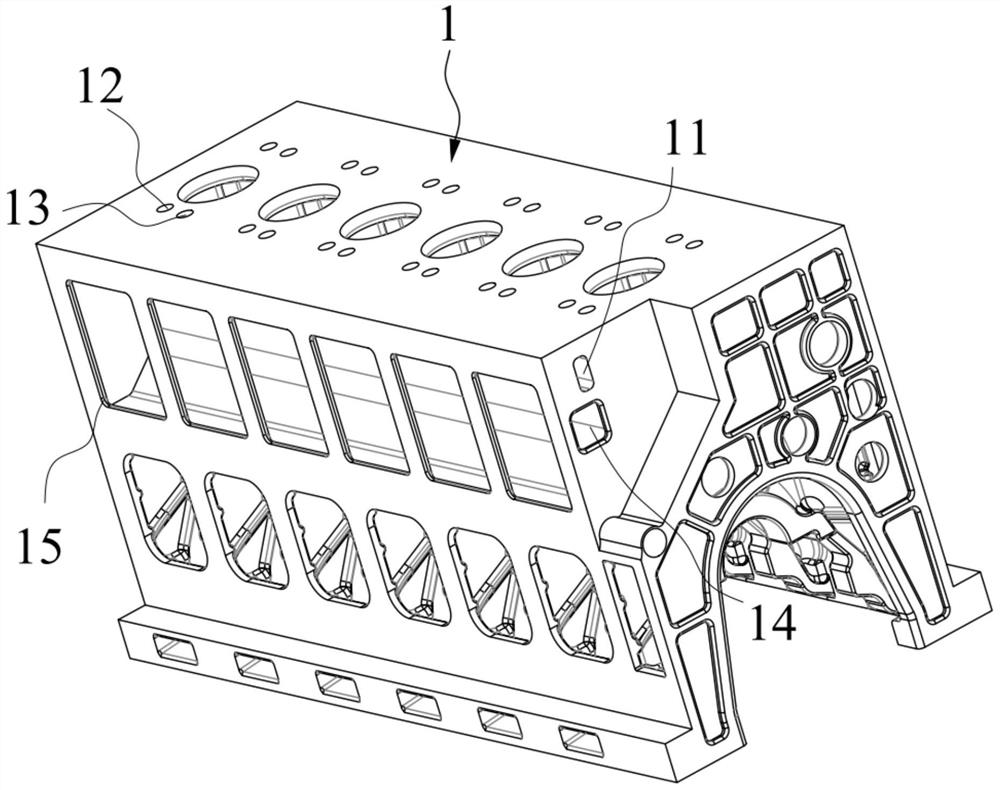

Engine body and diesel engine

PendingCN113323765AMiniaturizationPromote lightweight developmentCylinder headsCylindersMarine engineeringWater jacket

The invention relates to the technical field of engines, and particularly discloses an engine body and a diesel engine. The engine body comprises a machine body and an air cylinder water jacket arranged on the machine body, and the machine body is integrally provided with a high-temperature water main water inlet channel, a cylinder cover water jacket connecting channel, a high-temperature water drainage channel and a plurality of high-temperature water inlet branch channels. One end of each high-temperature water inlet branch channel communicates with the air cylinder water jacket, the high-temperature water main inlet channel communicates with the other end of each high-temperature water inlet branch channel, the cylinder cover water jacket connecting channel conveys cooling water in the air cylinder water jacket into the cylinder cover water jacket, and the high-temperature water drainage channel discharges the cooling water in the cylinder cover water jacket. According to the engine body, external pipelines on the machine body and a cylinder cover can be reduced, and then the development of miniaturization and light weight of an engine is facilitated.

Owner:CSSC POWER INST CO LTD

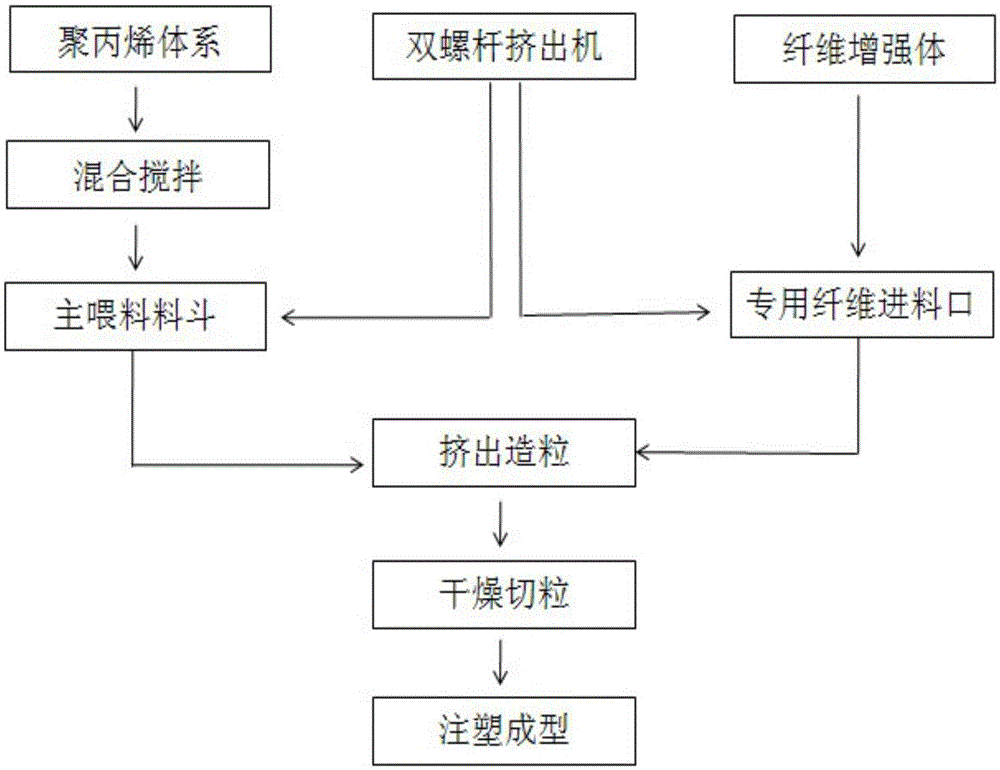

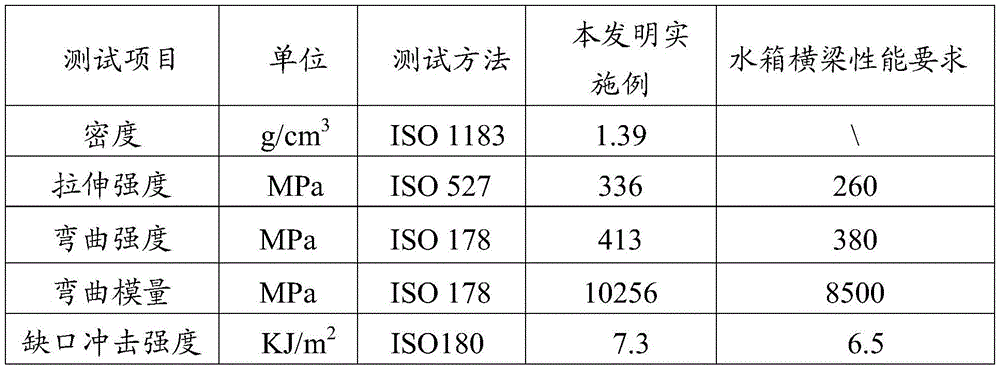

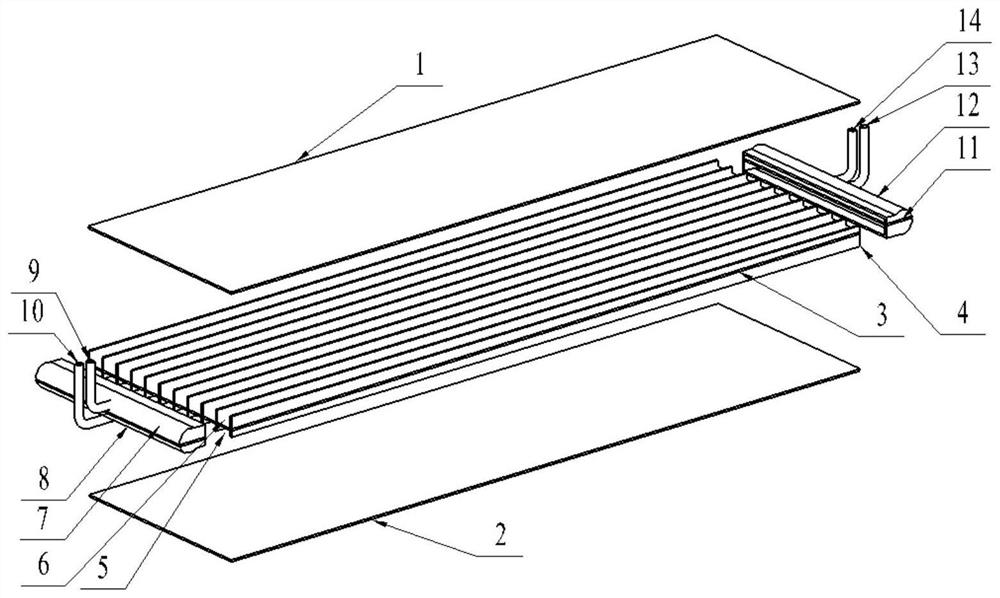

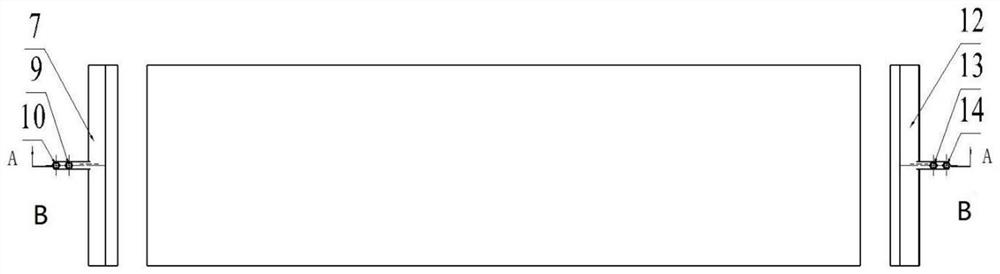

A kind of polypropylene composite material automobile water tank beam and preparation method

Owner:CHERY AUTOMOBILE CO LTD

A double-sided tapered liquid-cooling plate that can work on both sides

ActiveCN110890605BUniform coolingReduce consumptionSecondary cellsNew energyElectrical energy consumption

The invention relates to a double-sided cross-section tapered liquid-cooled plate that can work on both sides, including an upper cover plate, a lower cover plate, a plate body, a left header and a right header, and the upper cover plate It is arranged above the plate body, the lower side cover plate is arranged under the plate body, the left and right collectors are respectively arranged on the left and right sides of the plate body, and the plate body includes two layers of microchannel partitions , the cooling liquid flows in opposite directions in the upper and lower microchannels, and the cross-sectional area of the two layers of microchannel partitions in the direction of liquid flow gradually decreases. The double-sided cross-section tapered liquid cold plate of the present invention can work on both sides simultaneously while cooling the battery module more uniformly. Since one liquid cold plate can cool two batteries at the same time, the total number of liquid cold plates required by the battery system is greatly reduced, which can greatly reduce system space occupation and power consumption, and is conducive to the development of lightweight new energy vehicles.

Owner:JIANGSU UNIV

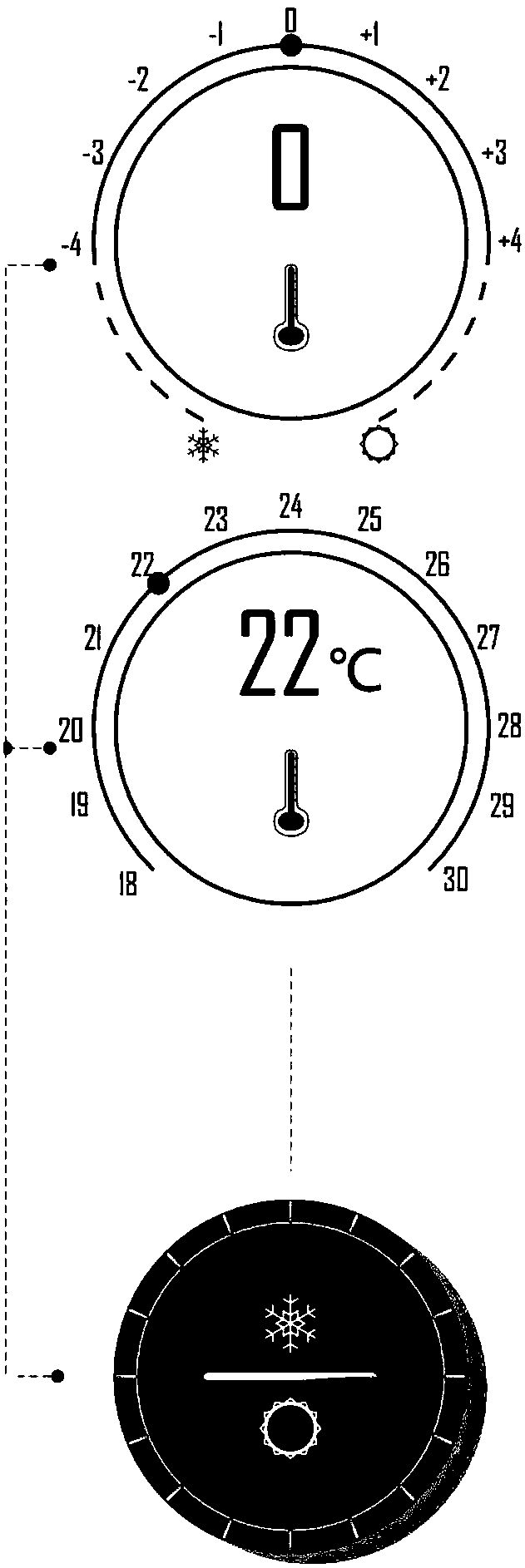

Control method of air conditioning system of electric vehicle

ActiveCN106143049BReduce energy consumptionPromote lightweight developmentAir-treating devicesVehicle heating/cooling devicesMiniaturizationAir conditioning

The invention discloses a control method for an air conditioning system of an electric automobile. The air conditioning system comprises a compressor, a heater and a draught fan. The air conditioning system has a standby state and a working state. In the working state, the air conditioning system has a refrigerating mode, a heating mode and a natural air mode. In the refrigerating mode, the compressor runs, and the heater is stopped. In the heating mode, the compressor is stopped, and the heater runs. The draught fan runs in both the refrigerating mode and the heating mode to blow the refrigerated air or heated air into a cab of the electric automobile. In the natural air mode, the compressor and the heater are both stopped, and the draught fan runs to blow air. By the adoption of the control method of the embodiment, the energy consumption and the system running cost of the electric automobile are reduced, the weight of a storage battery can be reduced, and the miniaturization and lightweight development of the electric automobile is facilitated as well.

Owner:BEIJING ELECTRIC VEHICLE

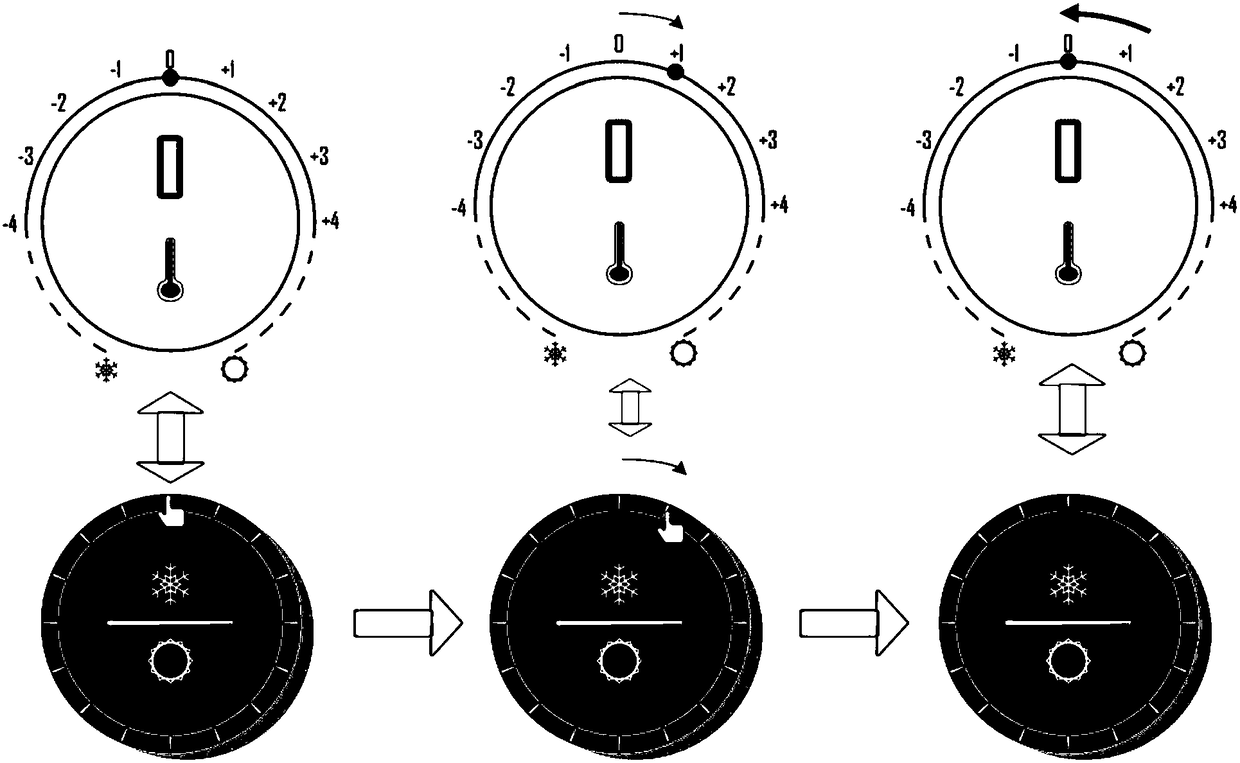

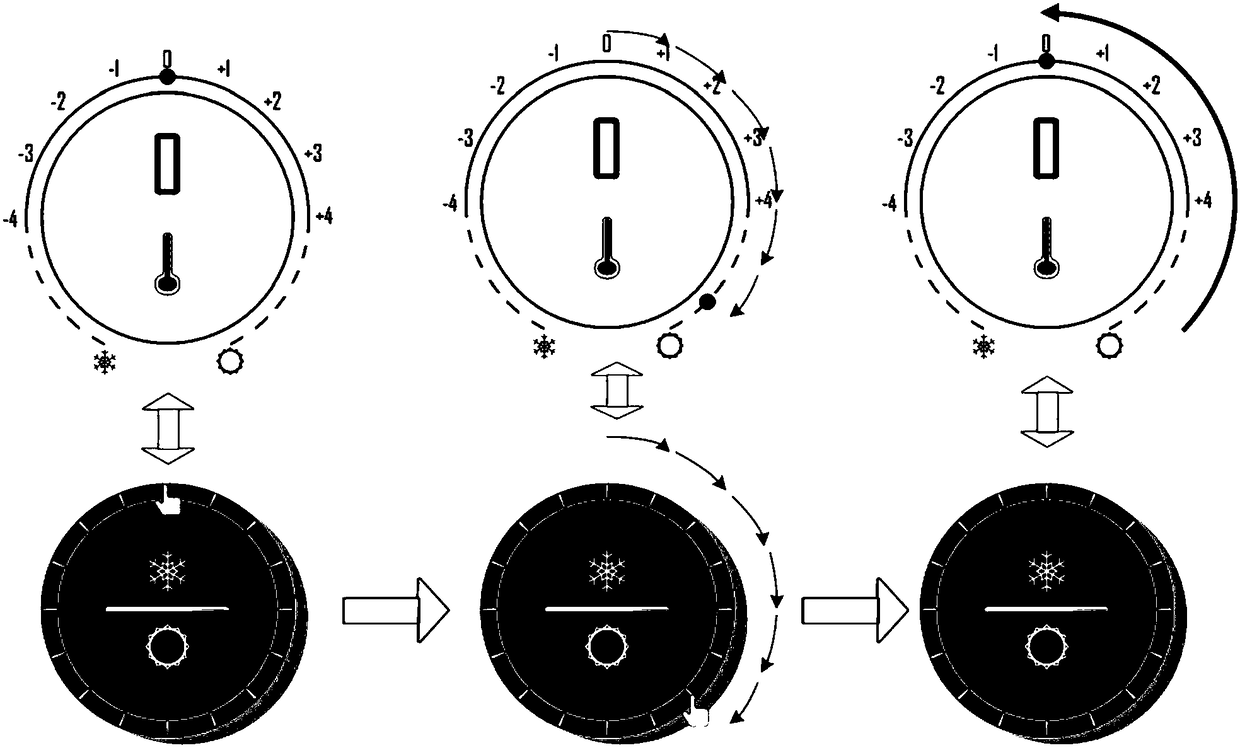

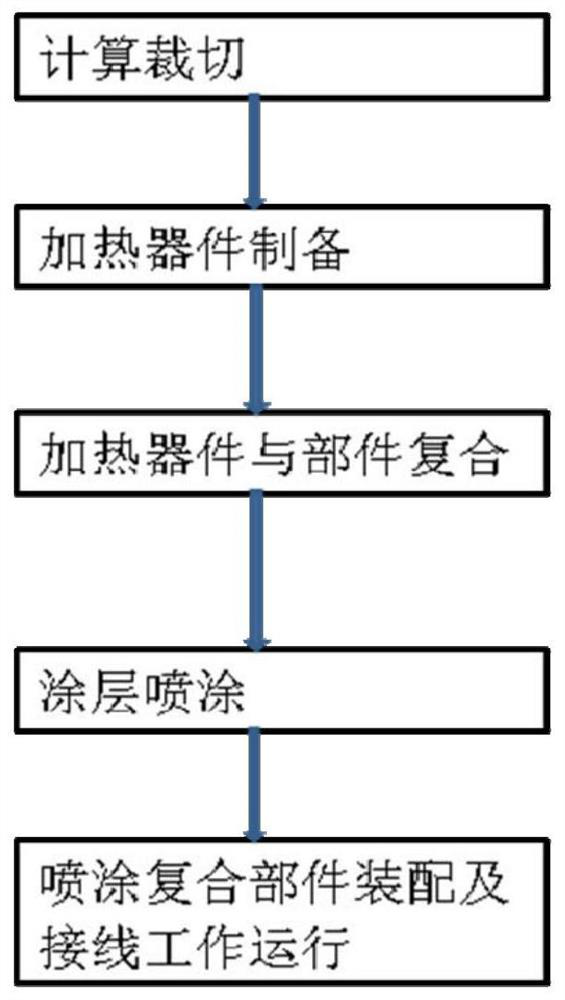

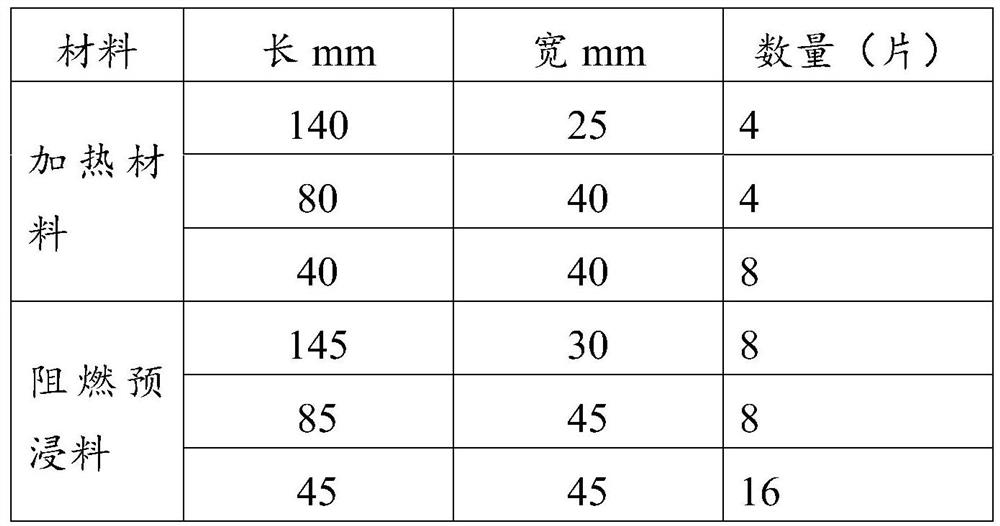

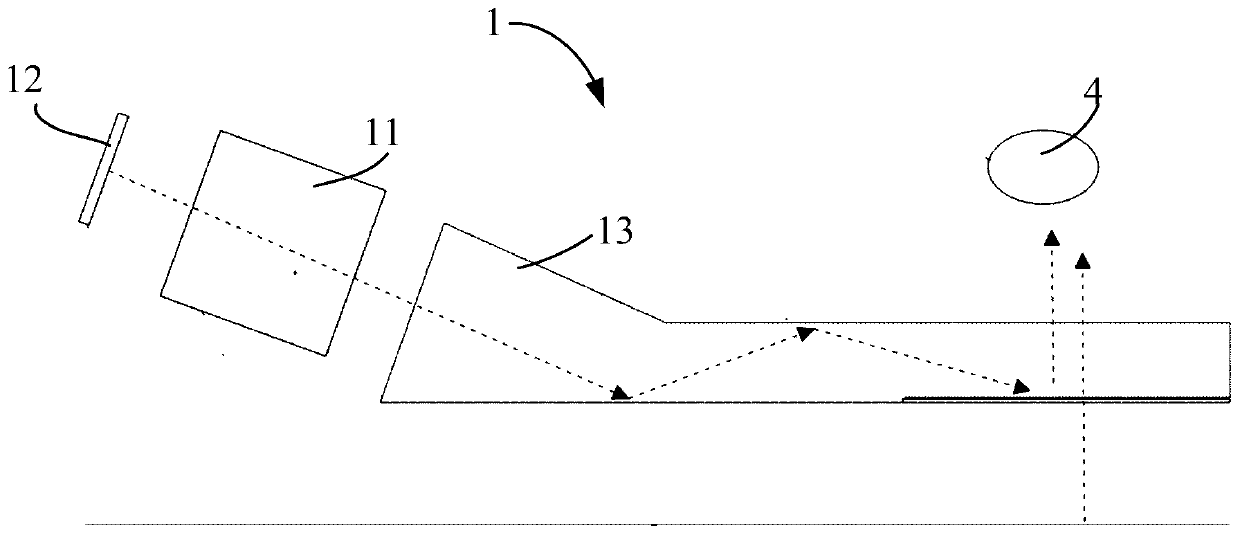

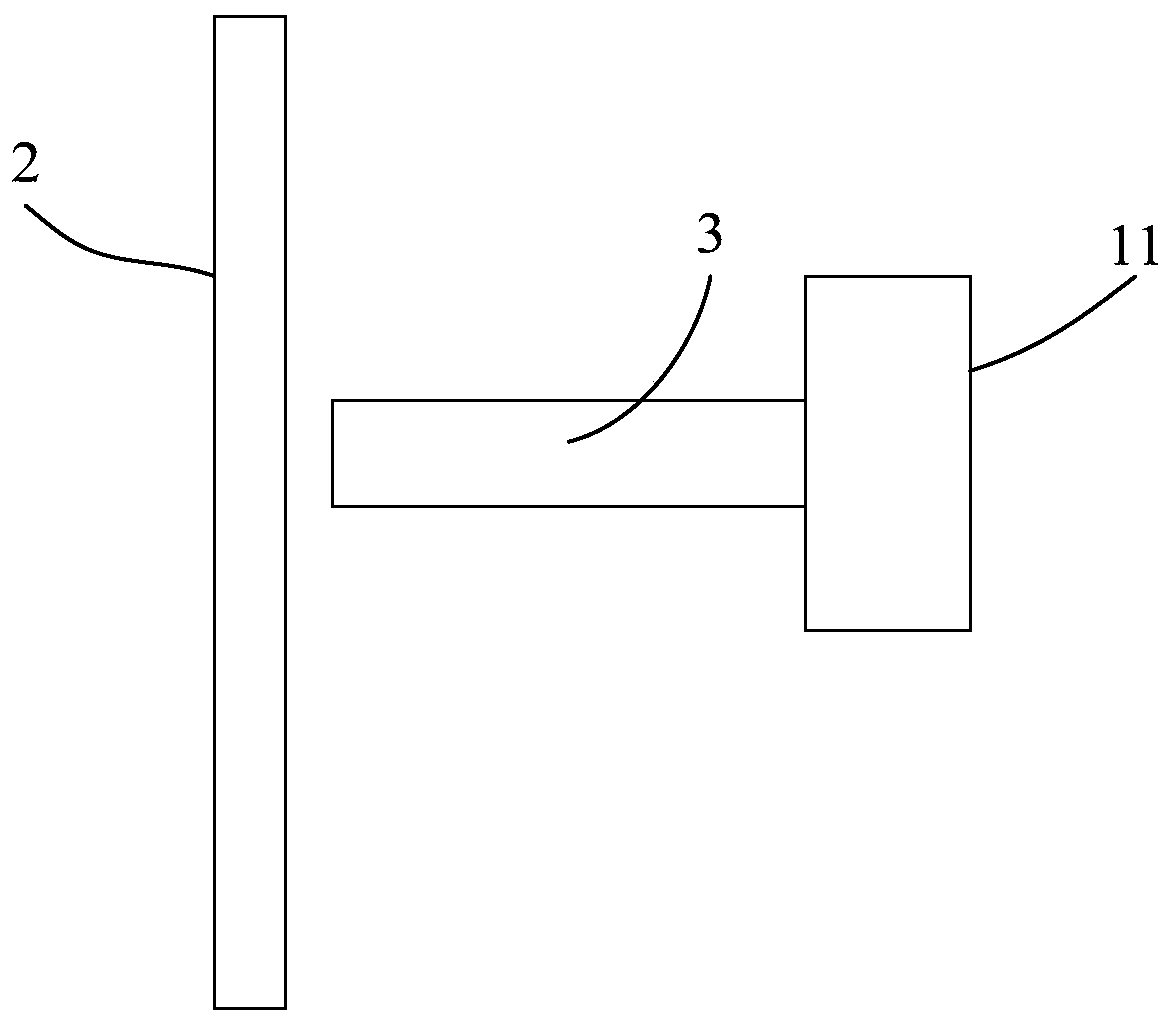

Manufacturing method of infrared composite heating device for ice prevention and removal and heating device

PendingCN111867168ADoes not affect heating performanceMeet the requirementsTransparent/reflecting heating arrangementsInsulation layerElectric wire

The invention relates to the field of vehicles, in particular to a manufacturing method of an infrared composite heating device for ice prevention and removal. The method comprises the following steps: 1), calculating and cutting a heating material, a packaging material and a lead; 2) sewing or fitting the lead and the heating material, and packaging and molding by using the packaging material toobtain a heating component; 3) performing packaging material insulation laying on a to-be-prevented-and-deiced part, then performing distribution and wire connection on the heating component on the insulation layer, and then performing packaging and coating on the heating component by using the packaging material to obtain a complex of the heating component and the to-be-prevented-and-deiced part;4) carrying out integrated composite forming on the composite body obtained in the step (3) to obtain the integrally-formed part, 5) spraying a hydrophobic layer on the integrally-formed part obtained in the step (4) to obtain the composite formed part with the hydrophobic coating, and 6) connecting the qualified composite formed part to a vehicle.

Owner:上海骏珲新材料科技有限公司 +1

Virtual display

The invention provides a virtual display. The virtual display comprises an optical assembly, a heat dissipation part and a heat conduction assembly, wherein the optical assembly comprises a projectionlens; the heat dissipation part is arranged on one side of the projection lens; and the heat conduction assembly is arranged between the projection lens and the heat dissipation part, and when the heat conduction assembly is in contact with the projection lens and the heat dissipation part, the heat conduction assembly is used for transmitting heat on the projection lens to the heat dissipation part. According to the virtual display, the stability of the display effect of the virtual display can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Control method of air conditioning system of electric vehicle

ActiveCN106042836BReduce energy consumptionMiniaturizationAir-treating devicesVehicle heating/cooling devicesMiniaturizationEngineering

The invention discloses a control method for an air conditioning system of an electric automobile. The air conditioning system comprises a compressor, a heater and a draught fan and has a standby state and a working state. In the working state, the air conditioning system has a refrigerating mode, a heating mode, a natural air mode and a defrosting mode. In the refrigerating mode, the compressor runs, and the heater is stopped; in the heating mode, the compressor is stopped, and the heater runs; in both the refrigerating mode and the heating mode, the draught fan runs so as to blow refrigerated or heated air into a cab of the electric automobile; in the natural air mode, both the compressor and the heater are stopped, and the draught fan runs to blow air; and in the defrosting mode, both the compressor and the heater are started to run. According to the control method, the energy consumption of the electric automobile and the running cost of the system are reduced, the weight of a storage battery can be better reduced, and miniaturization and lightweight development of the electric automobile are further facilitated.

Owner:BEIJING ELECTRIC VEHICLE

Control method for air conditioning system of electric automobile

ActiveCN106042836AReduce energy consumptionMiniaturizationAir-treating devicesVehicle heating/cooling devicesMiniaturizationEngineering

The invention discloses a control method for an air conditioning system of an electric automobile. The air conditioning system comprises a compressor, a heater and a draught fan and has a standby state and a working state. In the working state, the air conditioning system has a refrigerating mode, a heating mode, a natural air mode and a defrosting mode. In the refrigerating mode, the compressor runs, and the heater is stopped; in the heating mode, the compressor is stopped, and the heater runs; in both the refrigerating mode and the heating mode, the draught fan runs so as to blow refrigerated or heated air into a cab of the electric automobile; in the natural air mode, both the compressor and the heater are stopped, and the draught fan runs to blow air; and in the defrosting mode, both the compressor and the heater are started to run. According to the control method, the energy consumption of the electric automobile and the running cost of the system are reduced, the weight of a storage battery can be better reduced, and miniaturization and lightweight development of the electric automobile are further facilitated.

Owner:BEIJING ELECTRIC VEHICLE

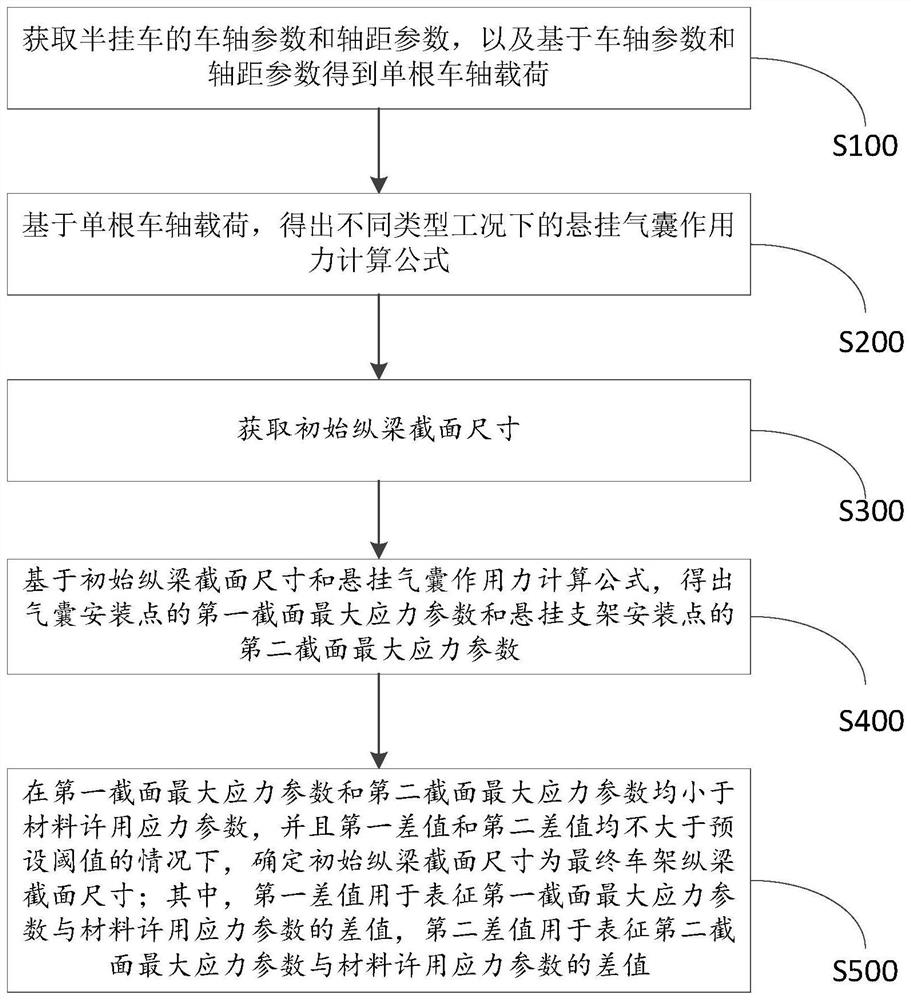

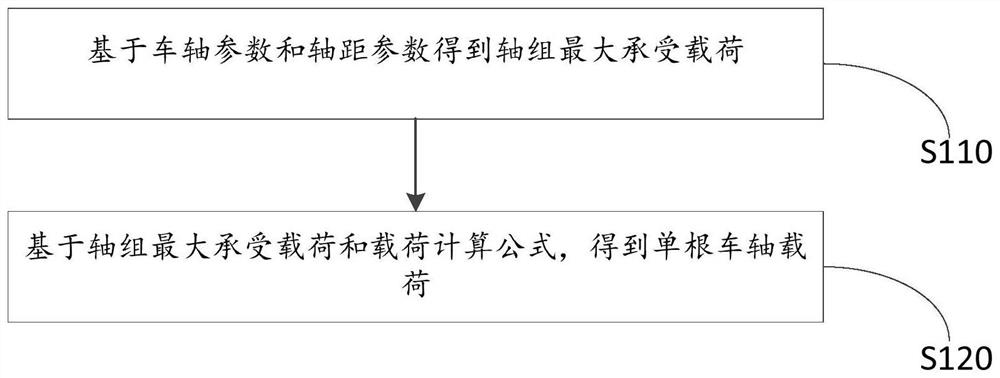

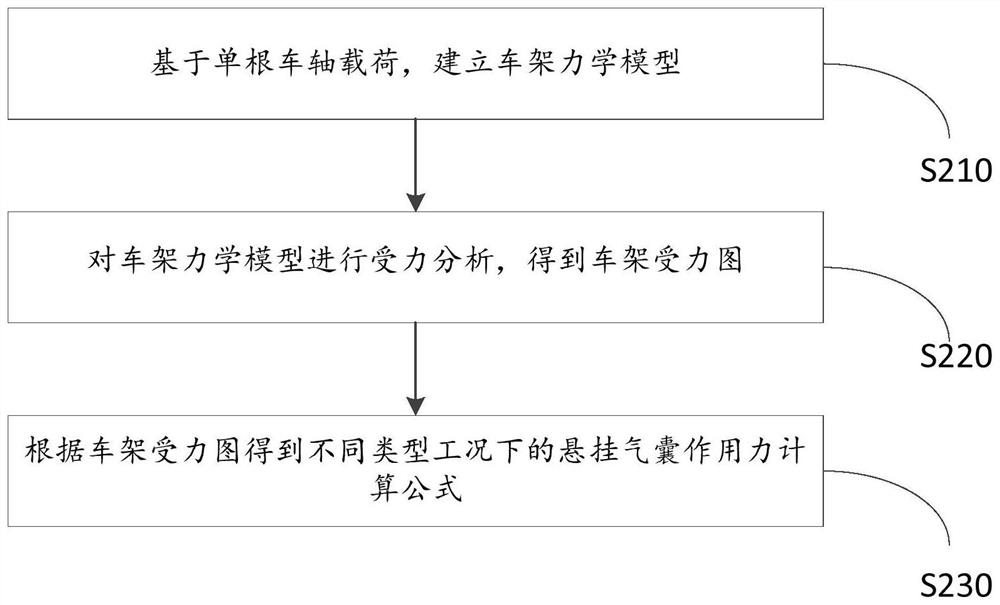

Method and equipment for calculating section size of frame longitudinal beam of liquid tank semitrailer, and storage medium

ActiveCN113722839APromote lightweight developmentSolve immature problemsGeometric CADSustainable transportationVehicle frameEngineering

The embodiment of the invention provides a method and equipment for calculating the section size of a frame longitudinal beam of a liquid tank semitrailer, and a storage medium. The method comprises the steps of obtaining axle parameters and axle distance parameters of the semitrailer, and obtaining a single axle load based on the axle parameters and the axle distance parameters; based on the load of a single axle, obtaining a suspension airbag acting force calculation formula under different types of working conditions; obtaining an initial longitudinal beam section size; obtaining a first section maximum stress parameter and a second section maximum stress parameter based on the initial longitudinal beam section size and a suspension air bag acting force calculation formula; and under the conditions that the first section maximum stress parameter and the second section maximum stress parameter are both smaller than the material allowable stress parameter and the first difference value and the second difference value are both not larger than a preset threshold value, determining the initial longitudinal beam section size as the final frame longitudinal beam section size. According to the method of the embodiment of the invention, the sectional dimension of the longitudinal member of the frame can be calculated quickly, simply and conveniently, and meanwhile, the lightweight development of the frame is further promoted.

Owner:JIANGMEN POLYTECHNIC

An all-aluminum carriage

ActiveCN106080805BMeet load requirementsPromote lightweight developmentLoading-carrying vehicle superstructuresStructural engineeringEngineering

The invention discloses a full-aluminum carriage. The full-aluminum carriage comprises a carriage framework and an aluminum skin. The carriage framework comprises a bottom edge frame, a sub longitudinal beam, a bottom edge frame transverse beam, a top edge frame and four side frame beams, wherein the bottom edge frame comprises four bottom edge frame beams which are connected with each other to form a rectangle, wherein the two parallel bottom edge frame beams are transverse bottom edge frame beams; and the other two bottom edge frame beams are longitudinal bottom edge frame beams; the bottom edge frame is provided with the sub longitudinal beam; the two ends of the sub longitudinal beam are connected with a transverse bottom edge frame beam in an inserted way; the bottom edge frame is provided with the bottom edge frame transverse beam; the two ends of the bottom edge frame transverse beam are connected with a longitudinal bottom edge frame beam in an inserted way; the bottom edge frame transverse beam is connected with the sub longitudinal beam in an inserted way; the top edge frame comprises four top edge frame beams which are connected with each other to form a rectangle; the corner of the bottom edge frame is connected with the corner of the top edge frame through the side frame beams; and each beam is made of aluminum alloy. According to the invention, as the beams are connected with each other in an inserted way, the carriage framework forms an integrated structure so that the carriage obtains enough rigidity and strength to satisfy loading requirements.

Owner:广西南南铝加工有限公司

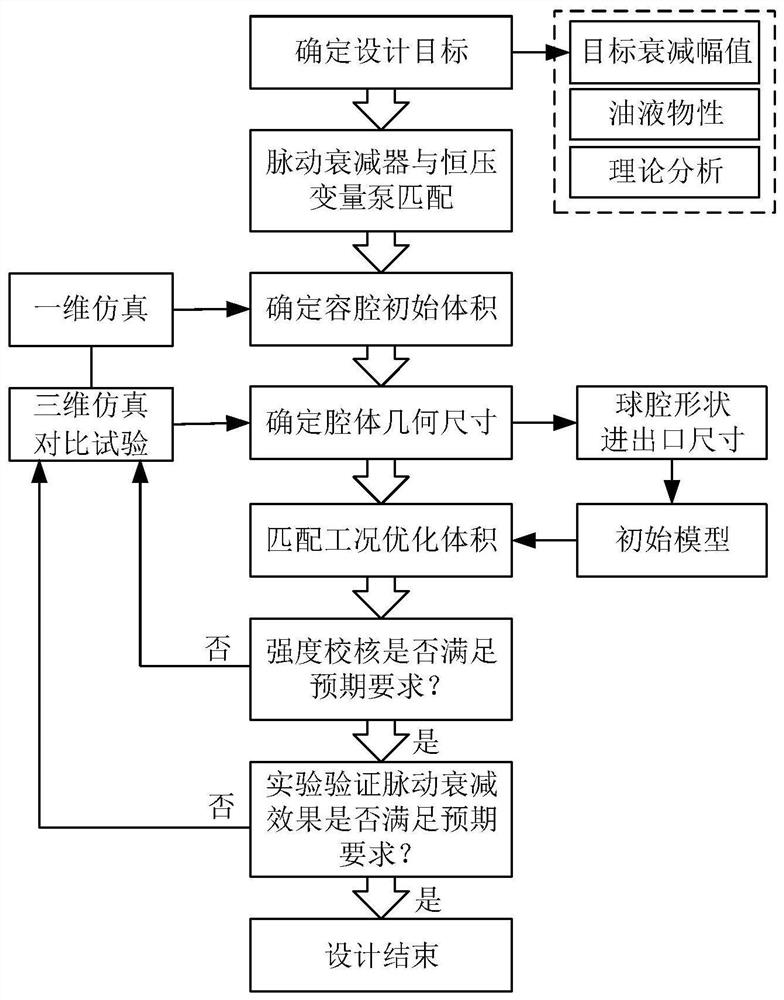

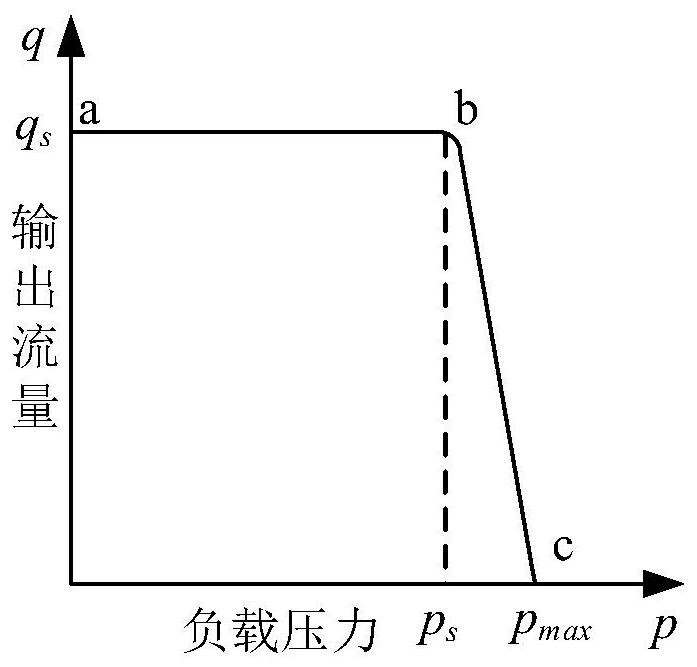

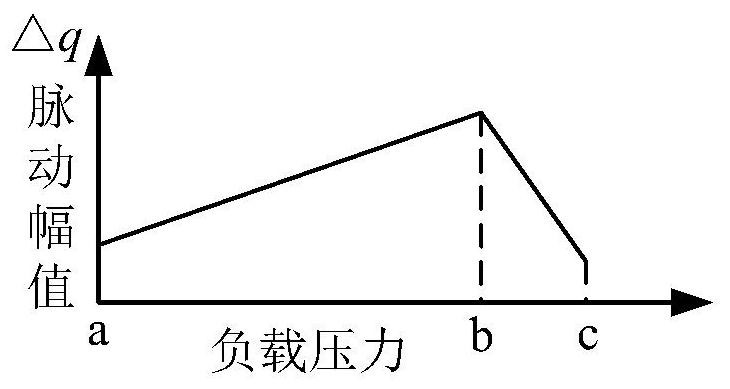

A design method of pressure pulsation attenuator integrated in constant pressure variable pump

ActiveCN111237293BReduce volumeImprove the attenuation effectFluid dynamicsPositive-displacement liquid enginesDimensional simulationDesign methods

The invention discloses a design method of a pressure pulsation attenuator integrated in a constant pressure variable pump, the steps are as follows: Step 1: determine the design target. Determine the working condition characteristics of the design object in the hydraulic system; Step 2: Match the pressure pulsation attenuator with the constant pressure variable pump, including flow matching, pulsation amplitude matching and pulsation frequency matching; Step 3: Determine the volume of the pressure pulsation attenuator cavity ; Step 4: Determine the geometric shape of the pulsation attenuator cavity; Step 5: Optimize the volume for matching working conditions; Step 6: Strength check and experimental verification. The method of the invention can directly attenuate the pulsation at the pulsation source without affecting other pipeline systems, has better attenuation effect, compact structure, and can reduce the volume of the entire hydraulic system. In the whole design process of the pressure pulsation attenuator, the present invention comprehensively uses theoretical calculation, one-dimensional and three-dimensional simulation and experimental verification methods to verify each other, which can improve the design quality and accuracy, and make the designed pressure pulsation attenuator model more feasible .

Owner:BEIHANG UNIV

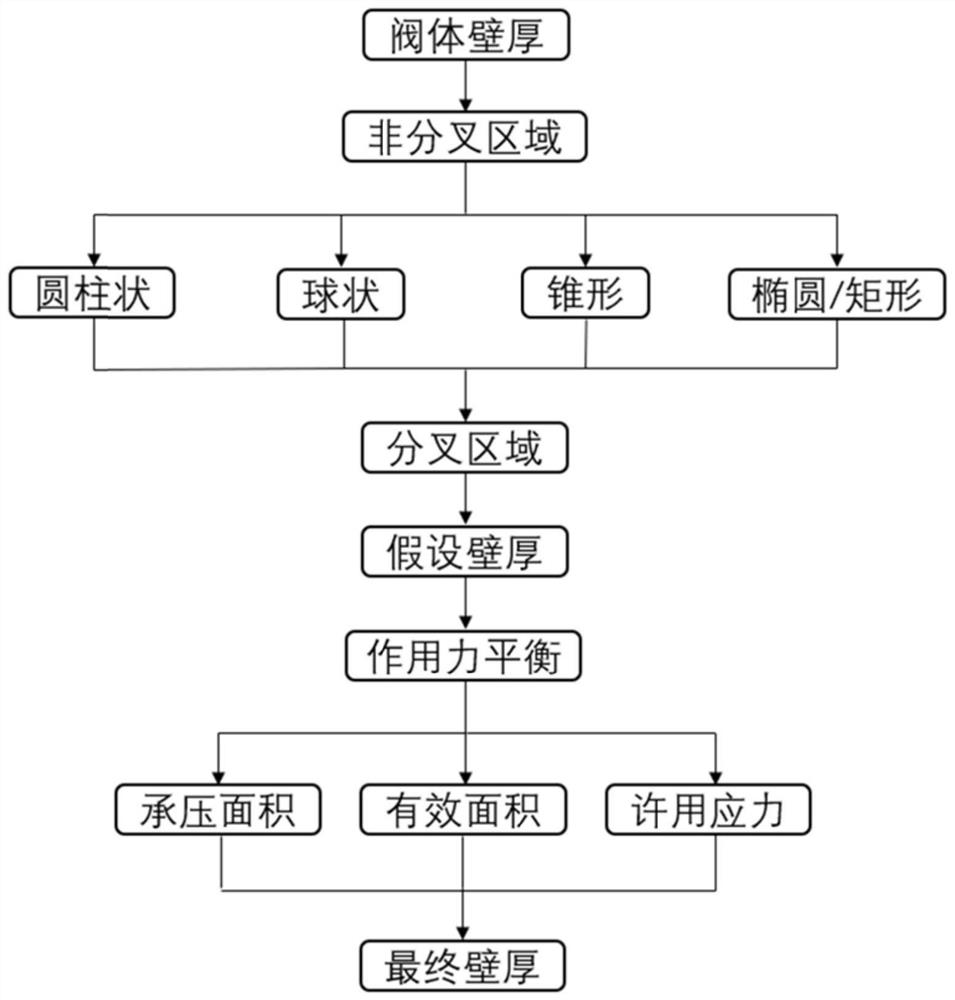

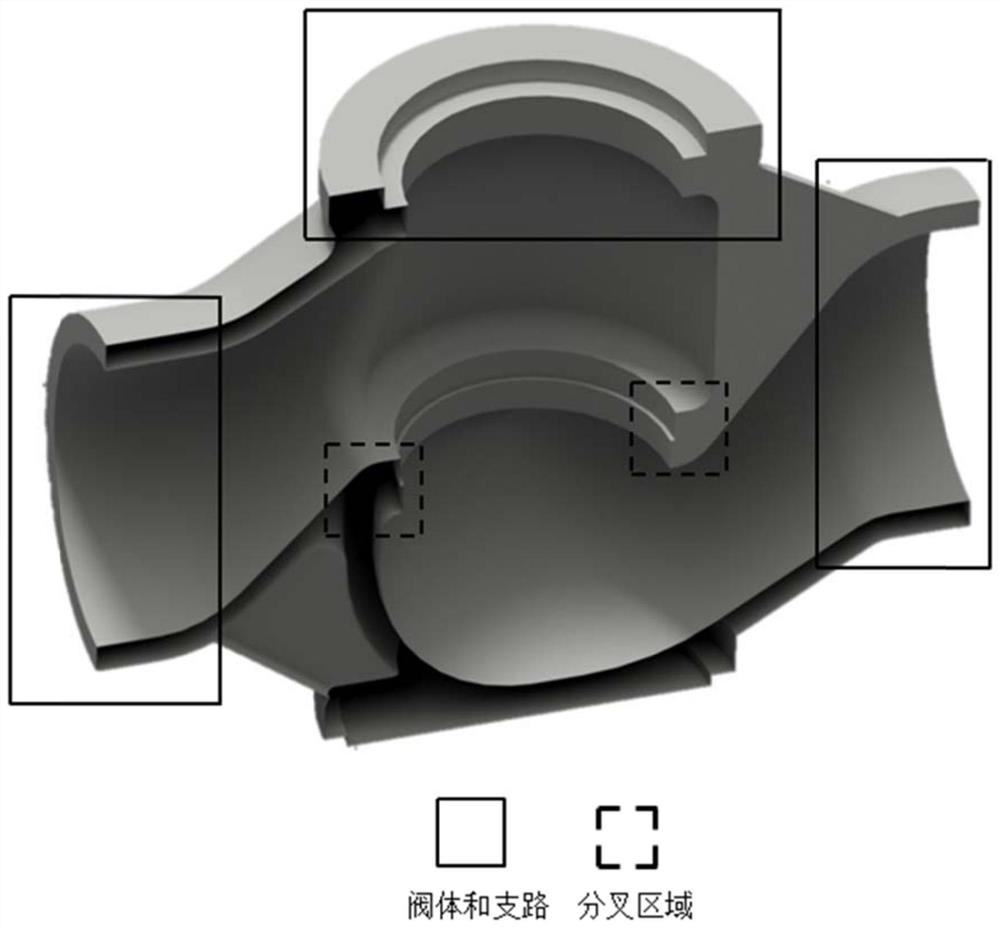

A method for calculating the wall thickness of an industrial steel valve body

ActiveCN111159829BScientific and reasonable wall thicknessAccurately reflect the stressGeometric CADCAD numerical modellingCalculation methodsIndustrial engineering

Owner:ZHEJIANG UNIV

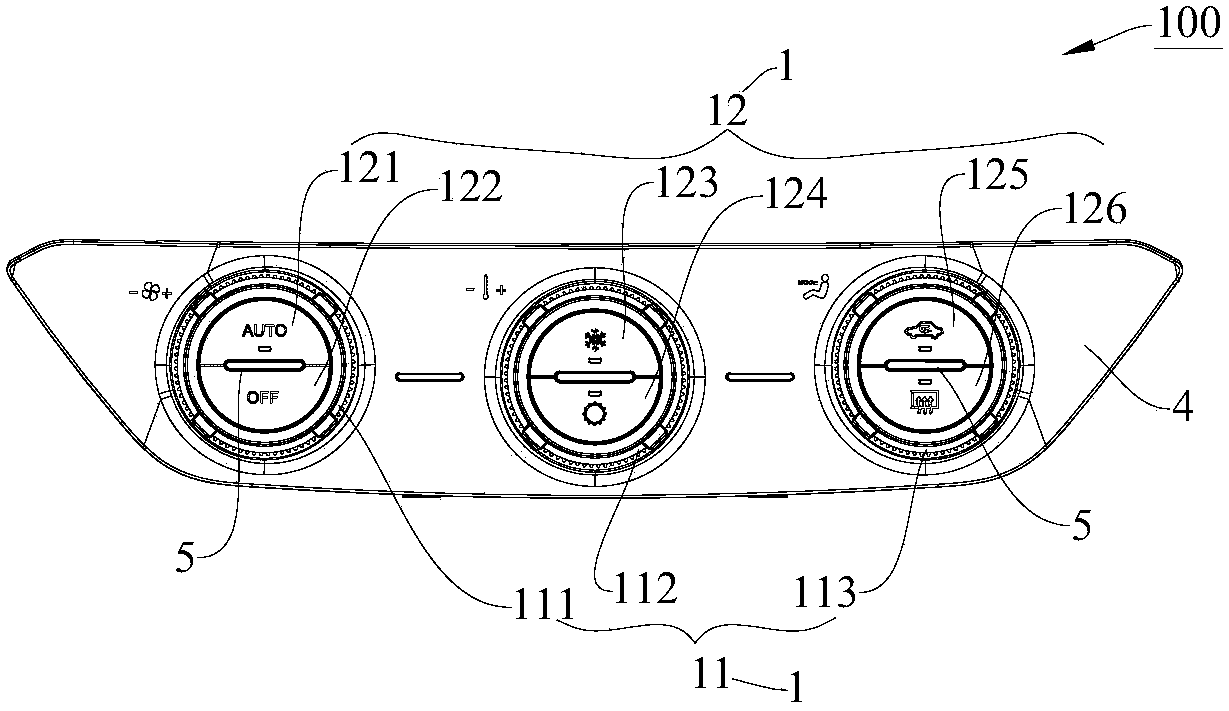

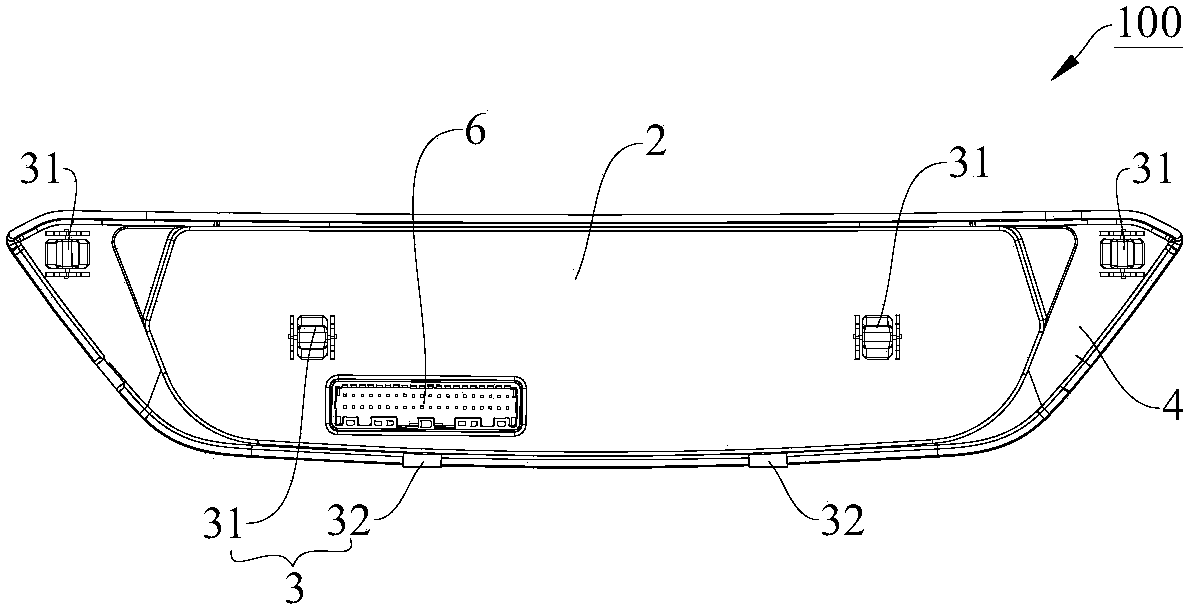

Control method of air conditioning system of electric vehicle

ActiveCN106114128BThe interior is simple and beautifulReduce energy consumptionAir-treating devicesVehicle heating/cooling devicesMiniaturizationEngineering

The invention discloses a control method for an air adjusting system of an electric car. In the refrigerating mode, a compressor is operated while a heater is turned off. In the heating mode, the compressor is turned off while the heater is operated. A fan is operated in both the refrigerating mode and the heating mode so as to blow cooled air or heated air into a cab of the electric car. In the natural wind mode, both the compressor and the heater are turned off, and the fan is operated to blow air. In the defrosting mode, both the compressor and the heater are started for operation. According to the embodiment of the control method for the air adjusting system of the electric car, the power consumption of the electric car and system operation cost are reduced, the weight of a storage battery is advantageously reduced, and miniaturization and lightweight development of the electric car is further facilitated. Fragmentary small display screens on an air conditioner control panel are omitted, and a display screen is used for displaying air conditioner operation information, so that the occupied area of the air conditioner control panel is reduced. In addition, the air adjusting system is simple and attractive in structure and has multiple control functions.

Owner:BEIJING ELECTRIC VEHICLE

Charging control method and system for electric vehicle and electric vehicle

ActiveCN109177809BReplenish electricity in timeImprove experienceBatteries circuit arrangementsElectric powerElectrical batteryCharge control

The present invention proposes a charging control method and system for an electric vehicle, and the electric vehicle. The method includes the following steps: detecting the voltage of the storage battery; judging whether the voltage of the storage battery is lower than the first preset voltage; if so, sending the battery low voltage to the user terminal Voltage reminder information and automatic charging request; after receiving the automatic charging instruction fed back by the user terminal, control the charging device to charge the battery. The present invention can send a reminder message and a charging request to the user when the voltage of the vehicle battery is too low, thereby facilitating timely replenishment of battery power, avoiding power loss caused by long-term parking of the vehicle, greatly facilitating the user, and requiring low cost and improving user experience.

Owner:CH AUTO TECH CORP CO LTD

Ultra-light hot-melt damping panel

InactiveCN107345076ALow densityMeet technical requirementsFilm/foil adhesivesBuilding insulationsHigh densityEngineering

The invention discloses an ultra-light hot-melt damping panel. The ultra-light hot-melt damping panel comprises the following materials by weight percent: 30.1-34.4% of pitch, 4.5-5.6% of modifier, 3.3-6.9% of additives, 5.1-6.2% of mica powder, 30.4-41.2% of calcium carbonate and 15.8-23.4% of glass beads. The ultra-light hot-melt damping panel can solve the problem of high density of the hot-melt damping panel at present. A high-performance hollow glass bead is used for replacing local calcium carbonate, so that the purpose of reducing the density of the damping panel is achieved.

Owner:盐城市宝光车用材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com