A design method of pressure pulsation attenuator integrated in constant pressure variable pump

A constant pressure variable pump and pressure pulsation technology, which is applied to fluid pressure actuation devices, fluid pressure actuation system components, pump components, etc., can solve problems such as pipeline deformation, ring breakage, and hydraulic system hazards, and achieve improved design Quality and precision, small volume and quality, good attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

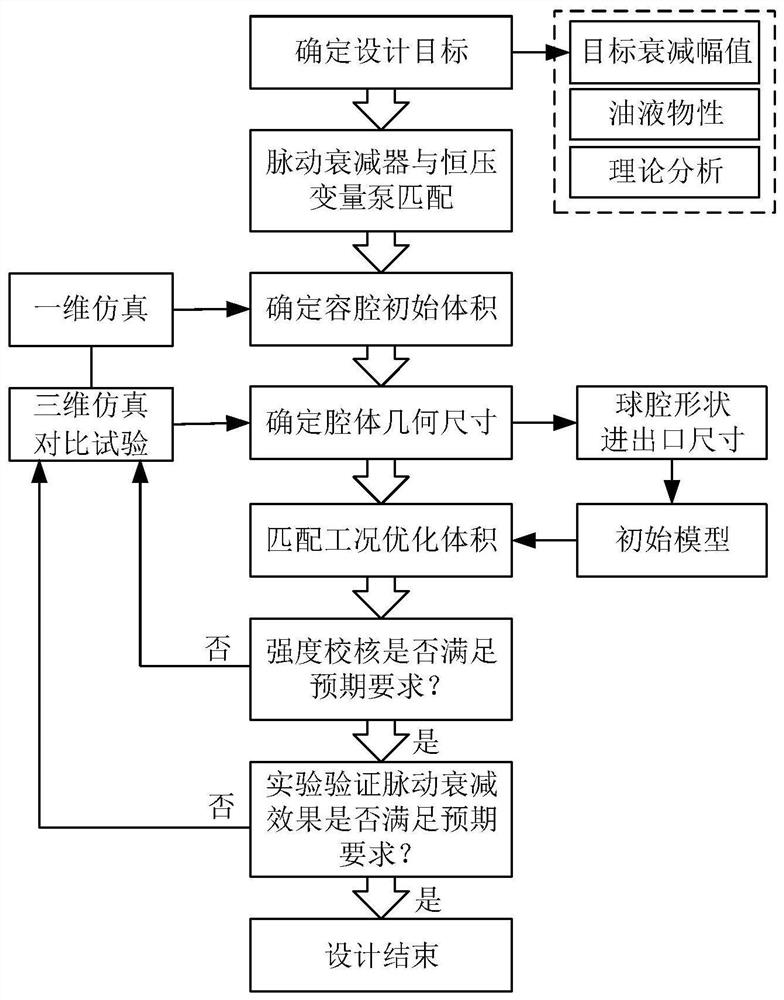

[0064] The design goal is: the rated displacement of a pump is 30 L / min, the rated pressure is 28MPa, the rated speed is 6000R / min; a hydraulic oil density is 900kg / m 3 , Volume elastic modulus 0.8 × 10 9 The PA, 40 ° C dynamic viscosity is 0.032Pa · s; the pressure pulse target amplitude is ± 1.4 MPa, and the maximum pressure drop value that can be accepted is 0.1 MPa.

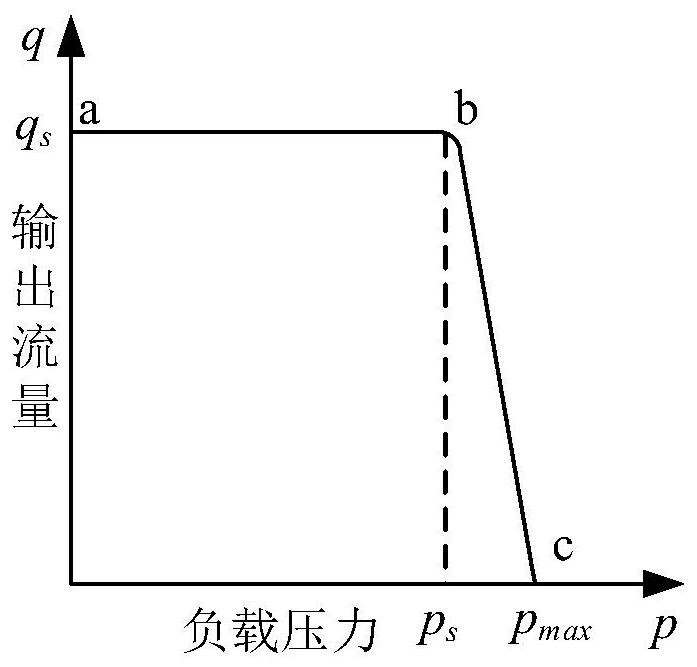

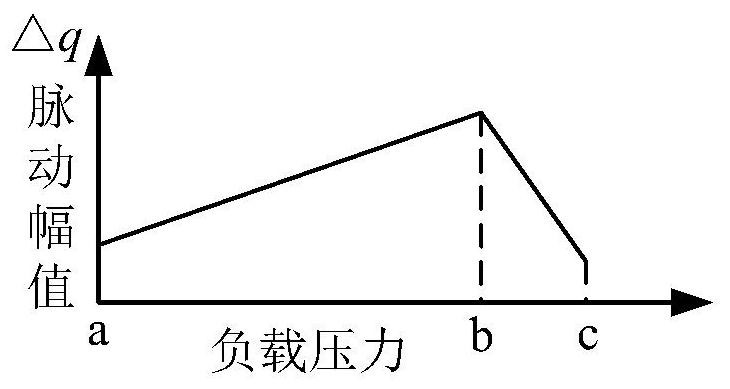

[0065] The pressure pulse attenuator matches the constant voltage variable pump, the flow match, according to the flow rate-pipe diameter requirements of the hydraulic system, the flow rate 30L / min high pressure hydraulic system corresponds to a minimum tube diameter of 8.9 mm, takes 9.5 mm; the pulsation magnitude is matched, according to the pulsation value The pump pressure-pulsating characteristic diagram, matching the maximum pressure pulse magnetic value; the pulsation frequency matches, the "hazard" matching of each speed is matched.

[0066] Determine the volume of the pulsation attenuator cavity,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com