Reparable carbon fiber electric-heating ice-melting chip and preparation method thereof

A technology of carbon fiber and carbon fiber bundles, which is applied in the field of repairable carbon fiber electric heating ice-melting chips and its preparation, can solve problems such as dry spots, air entrainment in blades, and affecting the heating performance of electric heating chips, so as to reduce the area, improve the natural environment, and reduce the The effect of electrification range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0041] This embodiment provides a repairable carbon fiber electric heating ice melting chip.

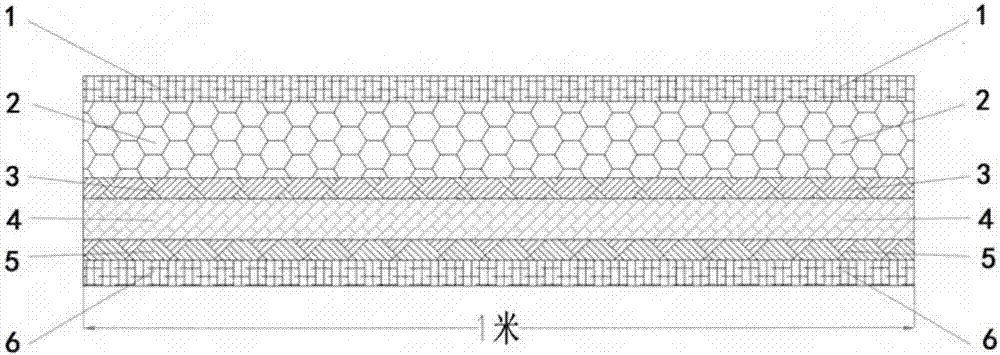

[0042] Preferably, the thickness of the chip is 0.4-1 mm, and it is named TYXK-N repairable electric heating chip in actual production.

[0043] Further, the structure of the repairable carbon fiber electric ice melting chip is that on the glass fiber cloth, there are carbon fiber bundles arranged in both warp and weft directions, and the warp and weft carbon fiber bundles are mutually conductive.

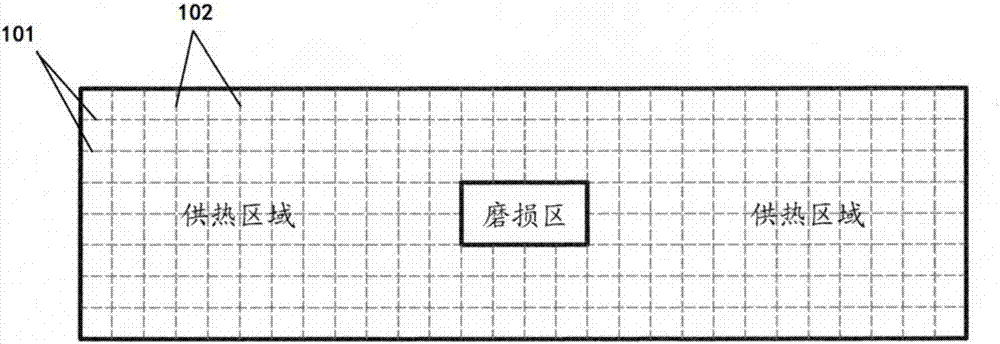

[0044] figure 2 This embodiment is a schematic diagram of the layout of the carbon fiber bundles in the repairable carbon fiber electric ice melting chip. figure 2 101 is a carbon fiber bundle in the warp direction, and 102 is a carbon fiber bundle in the weft direction. Such as figure 2 As shown, the repairable carbon fiber electric heating ice melting chip in this embodiment has a structure as follows: carbon fiber bundles are arranged in the warp and weft directions of the glass fiber clot...

no. 2 example

[0060] This embodiment provides a method for preparing a repairable carbon fiber electric heating ice melting chip (electric heating chip for short), and the method includes the following steps:

[0061] Step S1, mixing the glass fiber bundle and the carbon fiber bundle to obtain a chip fiber bundle.

[0062] The electric heating chip is based on glass fiber cloth, and its physical properties are similar to glass fiber cloth. It has the characteristics of regular shape (strip), soft texture and easy processing. It can be processed according to the processing method of glass fiber cloth and processed into Different shapes. Here, the preparation process of the electric heating chip is combined with the preparation process of the glass fiber cloth. The glass fiber bundle provides physical support for the chip, and the carbon fiber bundle provides electrical performance for the chip. When the carbon fiber bundles are sufficiently tough to support each other, the glass fiber bundles ca...

no. 3 example

[0070] This embodiment provides a method for preparing a repairable carbon fiber electric heating ice melting chip (electric heating chip for short), and the method includes the following steps:

[0071] Step S1: lay out carbon fiber bundles in the warp and weft directions on the glass fiber cloth.

[0072] Further, the carbon fiber bundles in the warp and weft directions include: a layer of warp carbon fiber bundles with a fixed pitch on top of a layer of weft carbon fiber bundles with a fixed pitch; or, a layer of weft carbon fiber bundles with a fixed pitch It is located on a layer of warp carbon fiber bundles with fixed intervals; or, the warp carbon fiber bundles and the weft carbon fiber bundles are arranged crosswise to form a network with each node crossing each other. When arranging a layer in the warp or weft direction, the carbon fiber bundle can be fixed on the glass fiber cloth by means of glue binding, pin nails or wire bundles. When arranging, keep a certain distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com