Automatic crushing device for aggregate production

An automatic and aggregate technology, applied in grain processing and other directions, can solve the problems of troublesome, time-consuming and laborious collection of crushed aggregates, and achieve the effect of reducing work content, reducing work difficulty, and facilitating collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

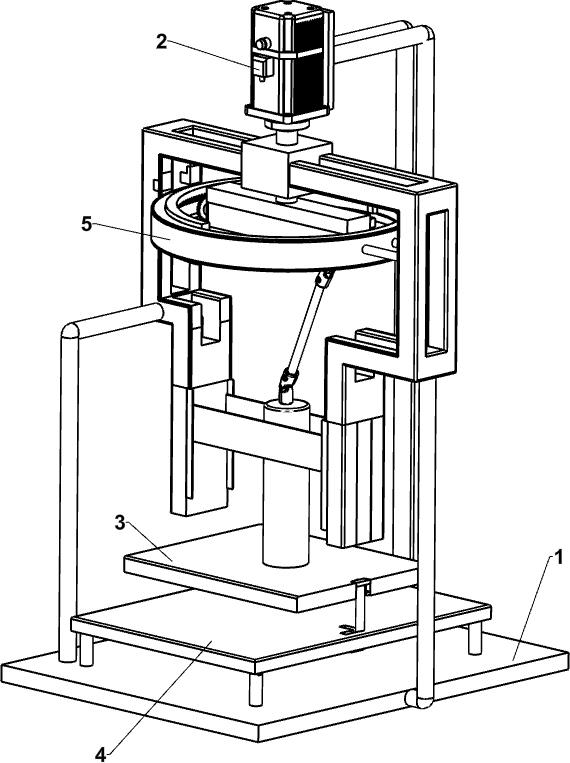

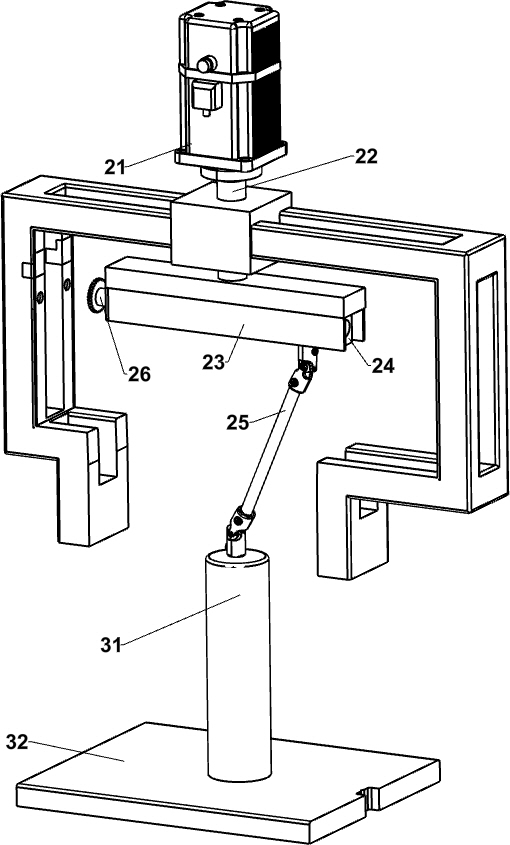

[0021] An automatic crushing device for aggregate production, such as Figure 1-2 As shown, it includes a frame 1, a lifting assembly 2 and a crushing assembly 3. The upper part of the frame 1 is provided with a lifting assembly 2 powered by a motor, and the bottom of the lifting assembly 2 is installed with a crushing assembly 3 that is crushed by lifting. .

[0022] When using this device for aggregate crushing, the raw material to be crushed is placed under the crushing assembly 3, and the lifting assembly 2 is controlled to lift, so that the crushing assembly 3 performs the crushing work. When the raw material to be crushed is crushed After crushing into qualified aggregates, the lifting assembly 2 is controlled to stop moving, and the aggregates are collected and taken out.

[0023] The lifting assembly 2 includes a reduction motor 21, a rotating rod 22, a guide rail 23, a slide block 24, a connecting rod 25 and a bolt 26, the top of the frame 1 is fixedly connected with...

Embodiment 2

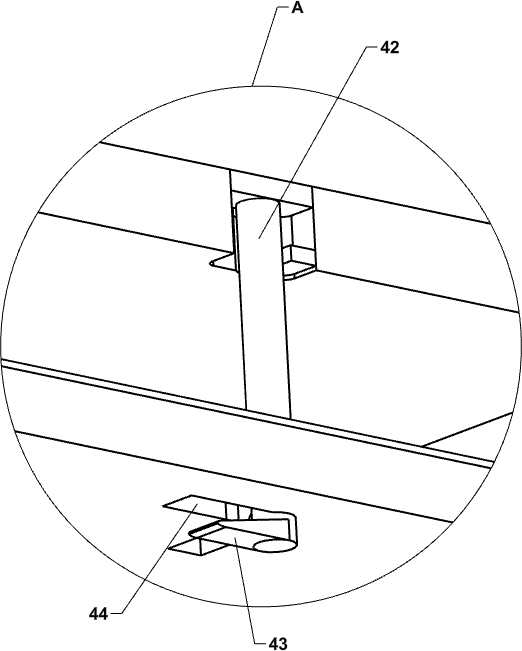

[0028] On the basis of Example 1, such as figure 1 , 3 , 4, 5 and 6, it also includes a placement assembly 4, the bottom of the frame 1 is equipped with a placement assembly 4, the placement assembly 4 includes a placement plate 41, a first connecting column 42 and a wedge block 43, the left side of the bottom of the frame 1 The side rotation type is provided with a placement plate 41, the right side of the pressing plate 32 is welded with a first connecting column 42, the bottom rotation type of the first connecting column 42 is provided with a wedge-shaped block 43, and the right part of the placement plate 41 has a through hole 44, and the through hole 44 and Wedge block 43 fits.

[0029] When using this device for aggregate crushing, the raw material to be crushed can be placed on the placement plate 41, and when the device completes the aggregate crushing work, turn the wedge-shaped block 43 so that it does not fit the through hole 44 , and then control the rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com