Efficient steel pipe cutting device

A cutting device and a high-efficiency technology, applied in the direction of pipe shearing device, shearing device, positioning device, etc., can solve the problems of low cutting efficiency and time delay, and achieve the effect of improving cutting efficiency, convenient cutting process, and convenient disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-5 The application is described in further detail.

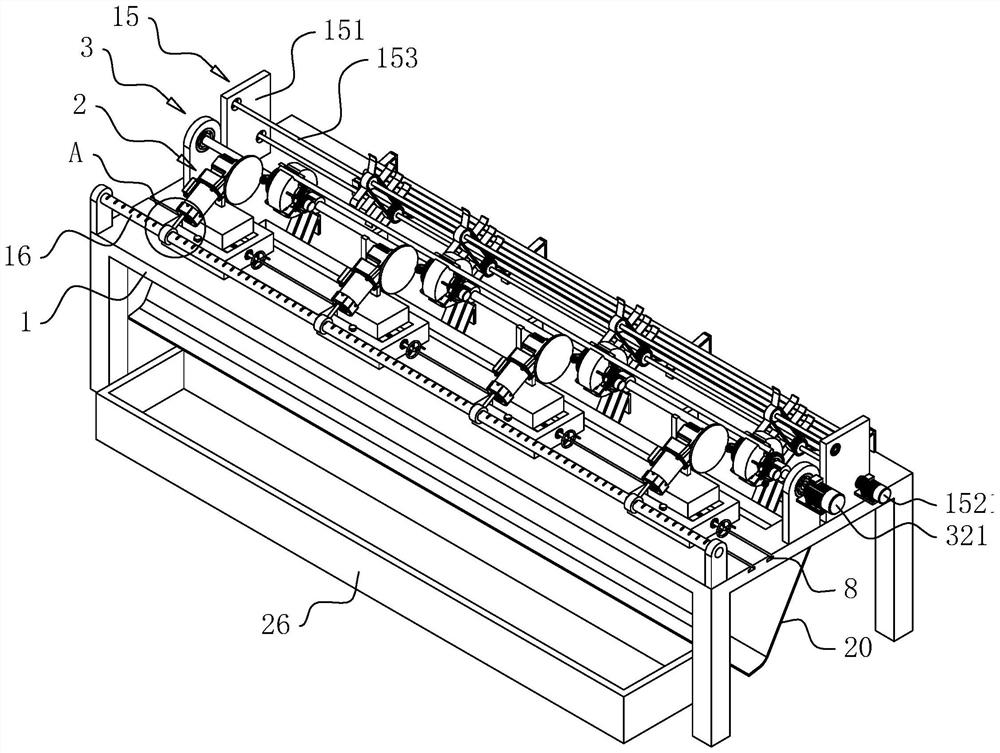

[0042] refer to figure 1 , is a high-efficiency steel pipe cutting device disclosed in the embodiment of this application. It includes a rectangular working platform arranged horizontally, and a plurality of legs for supporting the working platform 1 are arranged under the working platform. It also includes a cutting mechanism 2 arranged on the upper surface of one side of the workbench 1 in the length direction, and a plurality of cutting mechanisms 2 are provided along the length direction of the workbench 1 .

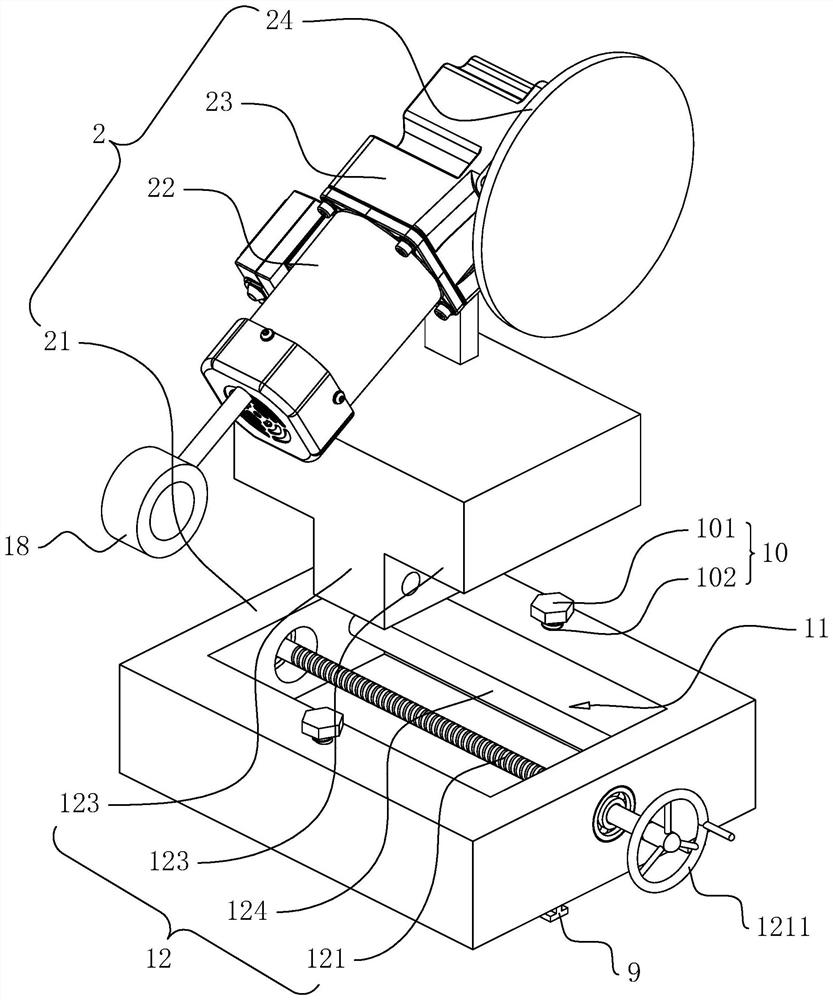

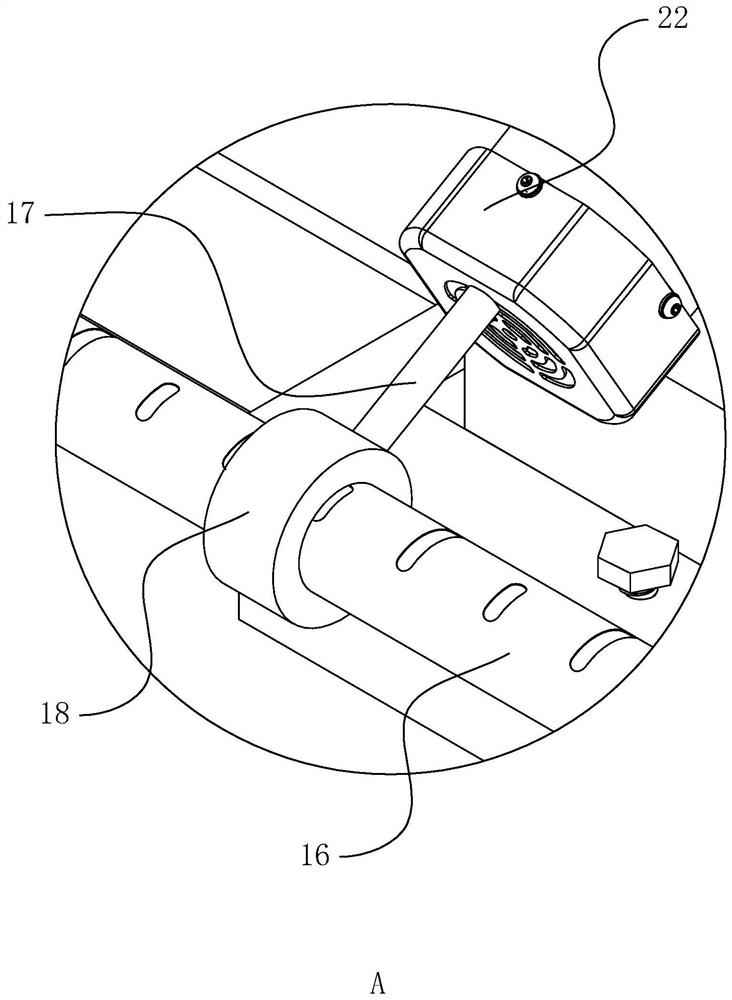

[0043] refer to figure 1 and figure 2 , the cutting mechanism 2 includes a base 21 arranged on the upper surface of the workbench 1, a cutting motor 22 arranged on the base 21, a reducer 23 arranged at the end of the cutting motor 22, and a cutting machine fixedly connected to the end of the output shaft of the reducer 23. disc 24 , the axis of the cutting disc 24 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com