Welding device for welding large-scale pipe fitting elbow

A welding device and elbow technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of complex fixed structure of elbow weldment and rotating disc, unstable speed of elbow weldment, and influence on welding quality, etc. , to achieve the effect of improving welding quality, convenient fixing, and stable rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

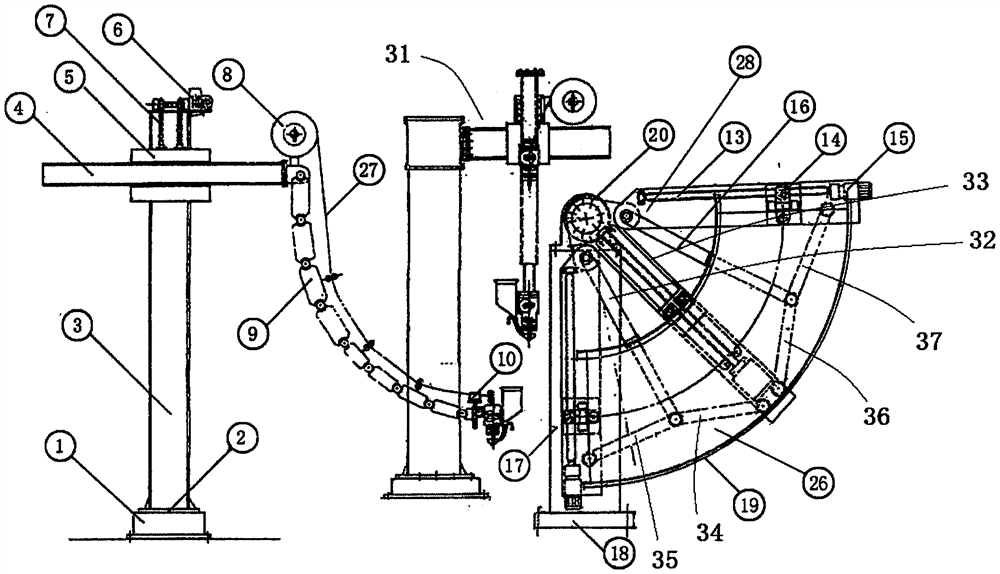

[0029] Welding device for welding elbow inner arc (inner R) welds

[0030] Such as figure 1 As shown, it includes a support that can be lifted. The support is composed of a frame 3, a lift frame 5, and a transverse arm 4. The transverse arm is installed on the lift frame 5. The lift frame can move up and down relative to the frame 3. The transverse arm 4 is connected to the welding arm. 9. A welding head 10 is provided at the end of the welding arm. The rotating disc 2 is fixed on the base 1 and can drive the frame 3 to rotate. The lifting motor 6 can drive the lifting frame 5 to move up and down through the lifting chain 7, and then drive the transverse arm 4 to move up and down. The transverse arm 4 is provided with a welding wire reel 8 , and a welding wire 27 is installed on the welding wire reel 8 , and the welding wire 27 is connected to the welding head 10 .

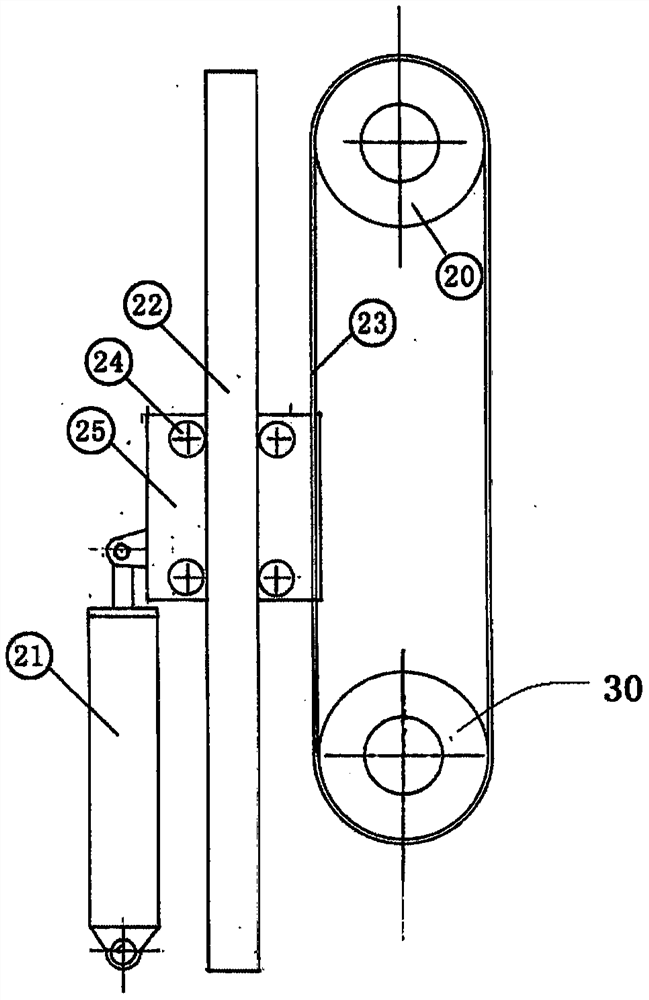

[0031] Such as figure 1 , figure 2 As shown, it also includes an elbow weldment clamping device. The elbo...

Embodiment 2

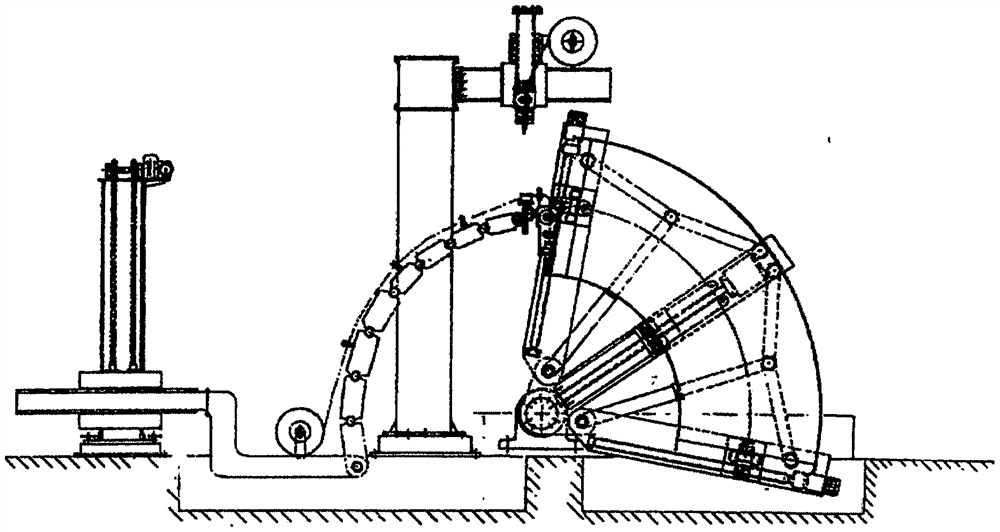

[0036] Welding device for welding elbow outer arc (outer R) welds

[0037] Such as image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that the overall welding arm is in the shape of an upwardly raised arc; the driving sprocket is located below the driven sprocket, and after the elbow weldment is clamped, the outer circle The arc weld seam corresponds to the position of the welding head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com